AAV Manufacturing 2025: Strategies for Scalability, Cost Reduction, and Regulatory Success

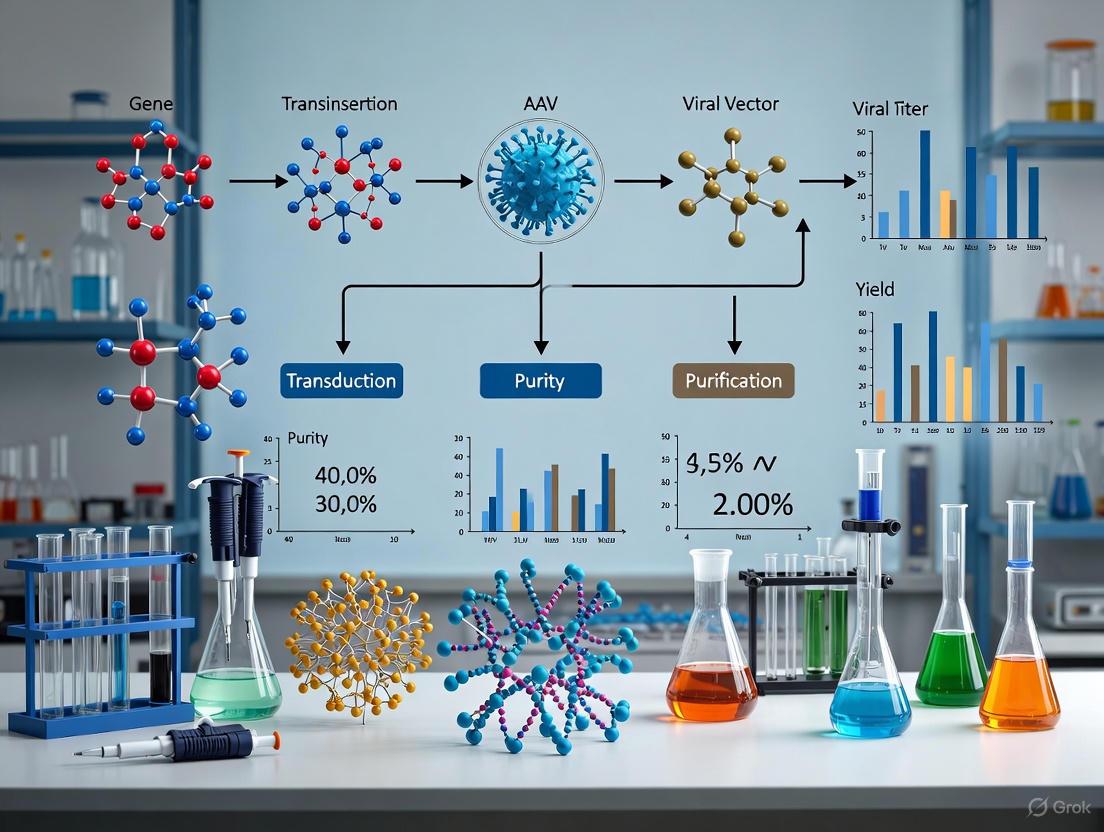

This article provides a comprehensive overview of the current state and future directions of Adeno-associated Virus (AAV) manufacturing for gene therapy.

AAV Manufacturing 2025: Strategies for Scalability, Cost Reduction, and Regulatory Success

Abstract

This article provides a comprehensive overview of the current state and future directions of Adeno-associated Virus (AAV) manufacturing for gene therapy. Tailored for researchers, scientists, and drug development professionals, it covers foundational AAV biology, detailed methodological workflows, and cutting-edge strategies for troubleshooting critical bottlenecks like high costs and empty capsids. By synthesizing the latest advancements in process development, analytical methods, and scalable production platforms, this guide serves as a strategic resource for navigating the complexities of AAV process development, optimization, and regulatory compliance from preclinical to commercial scales.

Understanding AAV: From Viral Biology to Therapeutic Vector

Adeno-associated virus (AAV) has emerged as a leading viral vector for human gene therapy due to its favorable safety profile, non-pathogenic nature, and ability to transduce a wide range of tissues. The structure of the AAV virion is elegantly complex, comprising three essential components: the protein capsid, the single-stranded DNA genome, and the inverted terminal repeats (ITRs) that flank the genome. These components work in concert to mediate cell targeting, efficient gene delivery, and genomic persistence. Understanding the biology and structure of AAV is fundamental to advancing its application in gene therapy, particularly in the context of viral vector manufacturing and capsid engineering strategies designed to overcome current limitations such as pre-existing immunity, suboptimal transduction efficiency, and limited tissue specificity [1] [2].

This application note provides a detailed overview of the AAV capsid, genome, and ITRs, framing their functions within the broader scope of AAV research and manufacturing. It includes structured quantitative data, detailed experimental protocols for key characterization assays, and visual workflows to aid researchers and drug development professionals in the analysis and engineering of AAV vectors.

Core Structural Components of AAV

The Capsid

The AAV capsid is a non-enveloped, T=1 icosahedral shell approximately 25 nm in diameter, assembled from 60 viral protein (VP) monomers [2] [3]. These monomers are derived from the cap gene and are present in a typical stoichiometric ratio of VP1:VP2:VP3 = 1:1:10 [2]. The VP proteins share a common C-terminal region (the VP3 domain), while VP1 and VP2 have unique, extended N-termini that are intrinsically disordered and reside inside the capsid [3].

The exposed surface of the capsid is formed by loops connecting the β-strands of the conserved VP3 β-barrel core structure. These loops are designated as variable regions (VRs I-IX) and are the primary determinants of the virus's interaction with its environment [3]. The variations in these VRs dictate serotype-specific traits, including receptor binding, tissue tropism, and antigenicity, which in turn determine the vector's efficacy and immunogenicity [1] [3].

Table 1: Key Characteristics of the AAV Capsid

| Characteristic | Description |

|---|---|

| Symmetry & Size | T=1 icosahedron, ~25 nm diameter [2] |

| Structural Proteins | VP1 (~82 kDa), VP2 (~67 kDa), VP3 (~60 kDa) [3] |

| Stoichiometric Ratio | Typically 1:1:10 (VP1:VP2:VP3) [2] |

| Key Surface Features | Variable Regions (VR I-IX), 3-fold protrusions, 2/5-fold wall, 5-fold pore [3] |

| Primary Functions | Host cell receptor binding, protection of genome, immune system interaction |

The Genome and Inverted Terminal Repeats (ITRs)

The recombinant AAV (rAAV) genome is a single-stranded DNA molecule, typically limited to a packaging capacity of less than 5 kb. The essential components of the rAAV vector genome are the inverted terminal repeats (ITRs) and the transgene cassette.

The ITRs are 145-base-pair hairpin-forming sequences that flank the transgene. They are the only viral cis-elements required for the AAV life cycle [2]. Their secondary structure formation is topologically dependent, requiring negative superhelicity to facilitate intra-strand base pairing [4]. Functionally, the ITRs serve as:

- Origins of DNA replication

- Primers for DNA synthesis

- Packaging signals for the genome into pre-assembled capsids [2] [4]

The transgene cassette, placed between the ITRs, contains all necessary elements for gene expression in the target cell, including a promoter, the therapeutic gene, and a polyadenylation signal [2].

Table 2: Composition of the Recombinant AAV Genome

| Component | Function | Key Features |

|---|---|---|

| Inverted Terminal Repeats (ITRs) | - Origin of replication- Primer for DNA synthesis- Genome packaging signal [2] [4] | - 145 bp palindromic sequences- Form T-shaped hairpin structures- Derived from AAV2 in most rAAV vectors |

| Promoter/Enhancer | Drives transcription of the transgene | Can be constitutive, inducible, or tissue-specific |

| Transgene | Encodes the therapeutic protein or RNA | Coding sequence for the therapeutic payload |

| Polyadenylation Signal | Ensures proper termination of transcription | Enhances mRNA stability and nuclear export |

The topology of the AAV genome is not limited to a single form. While single-stranded AAV (ssAAV) is the classical configuration, self-complementary AAV (scAAV) vectors are engineered to package an inverted repeat genome that can fold into double-stranded DNA upon uncoating, bypassing the rate-limiting step of second-strand synthesis and leading to faster transgene expression [5] [6]. Advanced sequencing techniques can distinguish these and other genome configurations, such as incomplete genomes (ICG) and genome deletion mutants (GDM) [5].

Figure 1: AAV Structural Component Relationships. This diagram illustrates the core structural components of AAV and their primary functions, highlighting how the capsid, genome, and ITRs contribute to the overall biology of the viral vector.

Quantitative Data and Analytical Methods

Accurate characterization of AAV vectors is critical for assessing the quality, safety, and potency of gene therapy products. Different analytical techniques provide complementary data on key attributes.

Table 3: Key Titers and Analytical Methods for AAV Characterization

| Titer Type | Units | Measurement Method | Significance |

|---|---|---|---|

| Capsid Titer | Capsid particles per mL (cp/mL) | ELISA [2] | Quantifies total assembled capsids (full and empty); important for immunogenicity assessment. |

| Genome Titer | Vector genomes per mL (vg/mL) | qPCR (after DNase treatment) [2] | Quantifies vector genomes available for transduction; used for clinical dosing (vg/kg). |

| Infectious Titer | Infectious Units per mL (IU/mL) | In vitro infectivity assay [2] | Measures biological activity of the vector; difficult to automate and standardize. |

| Full/Empty Ratio | Percentage (%) | Derived from comparison of genome and capsid titers; directly measured by AUC, TEM, or MP [2] [7] [6] | Critical quality attribute; impacts efficacy and safety. State-of-the-art processes achieve 8-30% full capsids [2]. |

The full-to-empty capsid ratio is a particularly critical attribute, as empty capsids not only lack therapeutic benefit but can also elicit immune responses that compromise efficacy and patient safety [2] [7]. Several orthogonal methods are employed to determine this ratio and characterize AAV products.

Table 4: Orthogonal Methods for AAV Capsid Population Characterization

| Method | Principle | Key Advantages | Key Limitations |

|---|---|---|---|

| Quantitative TEM (QuTEM) | Direct visualization and classification of capsids based on internal electron density [6] | - Direct visualization- Preserves structural integrity- High granularity | - Labor-intensive- Requires specialized expertise and equipment |

| Analytical Ultracentrifugation (AUC) | Separates capsids by mass/sedimentation velocity in a gravitational field [7] | - Considered a "gold standard"- High-resolution separation | - Requires large quantities of purified material- Labor-intensive [7] |

| Mass Photometry (MP) | Measures light scattering of individual particles to determine mass [7] [6] | - Fast, robust, and accurate- Requires minimal sample | - Not yet fully validated for commercial GMP use [7] |

| SEC-HPLC | Separates capsid species by size using chromatography [6] | - High-throughput potential- Amenable to automation | - Can lack resolution (baseline separation) [7] |

A recent comparative study demonstrated that QuTEM provides reliable quantification with high concordance to MP and AUC data, while offering the superior advantage of direct visual assessment of the capsids in their native state [6].

Detailed Experimental Protocols

Protocol 1: AAV Genome Sequencing via Nanopore Technology

This protocol outlines the steps for sequencing the AAV genome using Oxford Nanopore Technologies (ONT) to characterize genome integrity, ITR structure, and identify contaminants [5].

1. Pre-sequencing: Plasmid Construct Validation

- Purpose: Confirm the sequence of recombinant AAV (rAAV) plasmids and helper/repcap plasmids to reduce the likelihood of truncations and contaminating genomes in final preparations.

- Method: Use the ONT

Rapid sequencing V14 - Plasmid sequencingprotocol (SQK-RBK114.24 or SQK-RBK114.96) with thewf-clone-validationworkflow for assembly [5].

2. AAV Genome Extraction

- Recommended Method: Use the PureLink Viral RNA/DNA Mini Kit alongside DNase I treatment to remove unencapsidated DNA.

- Methods to Avoid: Heat, proteinase K, or phenol-chloroform treatments alone result in an increase in short reads and a decrease in full-length ITR-ITR genomes compared to the PureLink method [5].

3. Library Preparation

- Recommended Kit: Native Barcoding Kit 24 V14 (SQK-NBD114.24).

- Critical Step: Omit the self-annealing step. Direct ligation without annealing yields a faster library prep time and a higher number of full-length ssAAV genomes compared to high-temperature or low-temperature annealing protocols [5].

4. Sequencing and Analysis

- Sequencing: Perform on a MinION flow cell for ~72 hours using the High-accuracy (HAC) live basecaller.

- Analysis: Use appropriate EPI2ME workflows. The

itr_fl_thresholdparameter can be adjusted to define how many bases from the outer end of each ITR can be missed while still classifying a read as full-length [5].

Figure 2: AAV Genome Sequencing Workflow. The optimized protocol from sample to analysis, highlighting key recommendations for extraction and library preparation to maximize full-length genome recovery.

Protocol 2: Production of Recombinant Porcine AAV Vectors

This protocol describes the production of recombinant AAV vectors using porcine capsids (AAVpo.1, AAVpo.6), which are of interest for their ability to evade pre-existing human neutralizing antibodies and cross the blood-brain barrier [3].

1. Plasmid Construction

- Cap Gene Synthesis: Synthesize the entire cap gene of AAVpo.1 or AAVpo.6 (e.g., GenBank FJ688147, JX896664).

- Vector Plasmid Assembly: Amplify the porcine cap gene and a plasmid containing AAV2 rep and a placeholder cap gene (e.g., AAV5) via PCR. Use Gibson Assembly to replace the placeholder cap gene with the porcine cap gene, creating an

AAV2-rep-AAVpo.1-caporAAV2-rep-AAVpo.6-capplasmid. - Quality Control: Verify correct plasmid assembly by Sanger sequencing [3].

2. Triple Transfection in HEK293 Cells

- Cell Culture: Maintain HEK293 cells in DMEM with 10% FBS and 1% antibiotic-antimycotic at 37°C with 5% CO2.

- Plasmids for Transfection: Co-transfect HEK293 cells using the standard triple transfection method with three plasmids:

- Transgene Plasmid: e.g., pTR-UF3-Luciferase, containing the gene of interest flanked by AAV2 ITRs.

- Helper Plasmid: e.g., pHelper (Stratagene), providing adenoviral helper functions (E1, E2a, E4, VA).

- Packaging Plasmid: The constructed

AAV2-rep-AAVpo.1-caporAAV2-rep-AAVpo.6-capplasmid [3].

3. Harvest and Purification

- Harvest: 72 hours post-transfection, pellet cells by centrifugation.

- Lysis: Resuspend cell pellet in PBS. Lyse cells via three freeze-thaw-vortex cycles.

- Benzonase Treatment: Treat lysate with benzonase (0.1 µL/mL) for 1 hour at 37°C to degrade unpackaged nucleic acids.

- Clarification: Add NaCl to the lysate and clarify by centrifugation. Collect the supernatant containing the crude viral vector.

- Purification: Purify genome-containing particles using iodixanol density gradient ultracentrifugation [3].

- Characterization: Identify AAV-containing fractions via Western blot and determine genomic titer by qPCR.

The Scientist's Toolkit: Essential Research Reagents

Table 5: Key Reagents for AAV Vector Research and Production

| Reagent / Material | Function in AAV Research | Example Use Case |

|---|---|---|

| HEK293 Cell Line | A packaging cell line that provides necessary helper functions for AAV production. | Standard platform for transient transfection-based AAV production [2] [3]. |

| pHelper Plasmid | Plasmid providing adenoviral genes (E1, E2a, E4, VA) required for AAV replication and packaging. | One of the three plasmids in the standard triple transfection protocol [3]. |

| Rep/Cap Plasmid | Plasmid encoding the AAV Rep proteins (for replication) and Cap proteins (for capsid formation). | Can feature capsids from natural serotypes (e.g., AAV8, AAV9) or engineered variants (e.g., AAVpo.1) [2] [3]. |

| ITR-flanked Transgene Plasmid | Plasmid carrying the therapeutic gene of interest flanked by AAV2 inverted terminal repeats (ITRs). | Provides the "cassette" to be packaged into the AAV capsid [2] [3]. |

| Iodixanol | Non-toxic gradient medium used in density gradient ultracentrifugation. | Purification of genome-containing AAV particles from crude cell lysates [3]. |

| DNase I | Enzyme that degrades linear, unencapsidated DNA. | Treatment of AAV samples prior to qPCR to ensure only packaged genomes are measured [2] [5]. |

| Proteinase K | Broad-spectrum serine protease. | Digestion of viral capsids to release the genome for sequencing or titer analysis [5]. |

| Anti-AAV Capsid Antibodies | Antibodies specific to AAV capsid proteins. | Detection and quantification of total capsids (full and empty) via ELISA [2]. |

The structural components of AAV—the capsid, genome, and ITRs—form an integrated system that defines the vector's performance, safety, and manufacturability. Advances in analytical techniques, such as nanopore sequencing and quantitative TEM, are providing unprecedented insights into the complexity of AAV biology, from genome integrity and ITR topology to capsid heterogeneity. Concurrently, the exploration of novel capsids from non-primate sources, like porcine AAVs, offers promising paths to overcome the challenge of pre-existing immunity in human populations [3].

A deep understanding of AAV structure-function relationships is the foundation for the next generation of AAV vectors. As capsid engineering, genome design, and manufacturing processes continue to evolve through rational design, directed evolution, and computational approaches, the potential of AAV-based gene therapies to treat a wider array of genetic disorders will be greatly expanded [1] [2].

Adeno-associated virus (AAV) has emerged as the predominant viral delivery vehicle for in vivo gene therapy, marking a transformative era in the treatment of genetic disorders [8]. As a member of the Parvoviridae family, AAV is a small, non-enveloped virus with a single-stranded DNA genome of approximately 4.7 kilobases [2] [9]. Its journey from being identified as a contaminant in adenovirus preparations in the mid-1960s to becoming a cornerstone of modern gene therapy reflects its unique biological properties [10] [8]. The increasing adoption of AAV vectors is evidenced by the growing number of clinical trials and several approved therapies, such as Luxturna for inherited retinal dystrophy, Zolgensma for spinal muscular atrophy, and Hemgenix for hemophilia B [11] [12].

The fundamental appeal of recombinant AAV (rAAV) vectors lies in their ability to efficiently deliver therapeutic genes to both dividing and non-dividing cells while maintaining a favorable safety profile and enabling sustained transgene expression [9]. These characteristics address critical requirements for successful gene therapies, particularly for monogenic rare diseases requiring long-term correction. This application note examines the scientific foundation underpinning AAV's safety and durability advantages, provides detailed protocols for their evaluation, and discusses current challenges and innovative solutions in the field.

The Safety Profile of AAV Vectors

Non-Pathogenic Nature and Low Immunogenicity

The safety profile of AAV vectors is primarily rooted in their native biological characteristics. Wild-type AAV is naturally replication-deficient, requiring co-infection with a helper virus (such as adenovirus or herpes simplex virus) to complete its lytic cycle [9] [8]. This fundamental dependency is leveraged in vector design; recombinant AAV vectors lack the viral rep and cap genes necessary for replication, rendering them inherently incapable of autonomous replication and causing disease [9]. Unlike wild-type AAV, which can establish latent infection by integrating into a specific site on human chromosome 19 (AAVS1), recombinant AAV vectors are engineered without the rep gene, thus losing site-specific integration capability [9] [8].

The immunogenic properties of AAV vectors are notably favorable compared to other viral vectors. AAVs generally exhibit low immunogenicity, eliciting relatively mild immune responses, which is crucial for both safety and the potential for re-dosing [12]. While the prevalence of neutralizing antibodies against various AAV serotypes in the human population presents a clinical consideration, the capsid itself triggers minimal inflammatory responses [8]. This benign immunological profile has been demonstrated in long-term clinical studies; a 13-year follow-up of patients treated with AAV gene therapy for severe hemophilia B reported no development of factor IX inhibitors, thrombosis, or chronic liver injury, with adverse events primarily limited to transient elevations in aminotransferase levels [13].

Table 1: Key Safety Attributes of AAV Vectors

| Safety Attribute | Biological Basis | Clinical Implication |

|---|---|---|

| Non-pathogenic | Replication deficiency; requires helper virus for replication [9] [8] | No risk of causing viral disease |

| Minimal Genomic Integration | Lack of Rep78/68 proteins prevents site-specific integration into AAVS1 site [9] | Reduced risk of insertional mutagenesis |

| Low Immunogenicity | Limited inflammatory response to capsid and transgene products [8] [12] | Lower risk of immune-mediated adverse events |

| Episomal Persistence | Forms circular concatemers in nucleus without integration [9] | Stable transgene expression without genomic disruption |

Mitigating Genotoxic Risk

A significant safety advantage of AAV vectors is their predominantly episomal behavior in transduced cells. Following cellular entry and nuclear import, the single-stranded AAV genome is converted into double-stranded DNA, which subsequently undergoes ITR-mediated circularization to form stable episomal circular monomers or concatemers [9] [8]. This extrachromosomal persistence allows for long-term transgene expression without disrupting the host genome architecture. While random integration at low frequencies (0.01% to 3%, depending on cell type and vector concentration) can occur, the majority of rAAV DNA remains episomal [9]. This minimal integration profile substantially reduces the risk of insertional mutagenesis that has been associated with other viral vectors, particularly retroviruses.

The field continues to address safety considerations through vector engineering and manufacturing improvements. Concerns regarding immune responses to high systemic doses, potential genotoxicity, and off-target effects are actively being researched [8]. Strategies to mitigate these concerns include further engineering of capsids to evade pre-existing immunity, developing tissue-specific promoters to restrict transgene expression, and implementing advanced purification methods to remove empty capsids that contribute to immunogenicity [2] [14].

Long-Term Transgene Expression

Mechanisms of Persistence

The capacity of AAV vectors to mediate long-term transgene expression represents one of their most valuable therapeutic attributes. This durability stems from multiple biological factors that enable persistent transgene expression without genomic integration. The primary mechanism involves the formation of episomal circular concatemers in the nucleus of transduced cells [9]. Following second-strand synthesis, the linear AAV genome circularizes via its inverted terminal repeats (ITRs), forming stable episomes that are capable of persisting in non-dividing cells for extended periods, often for years [9] [8]. These episomal structures develop chromatin-like organization that protects them from degradation and allows for sustained transcriptional activity.

The stability of these episomal forms has been demonstrated in clinical settings with remarkable outcomes. A landmark study published in 2025 reported stable factor IX expression over 13 years of follow-up in patients with severe hemophilia B who received a single infusion of AAV gene therapy [13]. The mean factor IX levels remained stable across dose cohorts (1.7 IU/dL in low-dose, 2.3 IU/dL in intermediate-dose, and 4.8 IU/dL in high-dose groups), demonstrating the remarkable persistence of transgene expression achievable with AAV vectors [13]. This sustained expression translated directly to clinical benefit, with the median annualized bleeding rate decreasing from 14.0 to 1.5 episodes, representing a reduction by a factor of 9.7 [13].

Clinical Evidence of Durability

The durability of AAV-mediated transgene expression has been observed across multiple target tissues and disease states. In the central nervous system, AAV vectors have demonstrated persistent transgene expression for years in large animal models and human trials. Similarly, in retinal disorders, a single administration of AAV-based therapies has shown maintenance of therapeutic benefit for multiple years. The long-term follow-up data from hemophilia B trials provides particularly compelling evidence, with patients maintaining therapeutic factor IX levels for over a decade without necessitating re-administration [13].

Table 2: Evidence Supporting Long-Term AAV Expression

| Evidence Type | Findings | Therapeutic Implications |

|---|---|---|

| Clinical Evidence (13-year follow-up) | Stable FIX activity (4.8 IU/dL in high-dose group); reduced annualized bleeding rate from 14.0 to 1.5 [13] | Single administration can provide durable clinical benefit for over a decade |

| Molecular Studies | Episomal circular concatemers persist in non-dividing cells; chromatin-like organization [9] | Explains mechanism for long-term expression without genomic integration |

| Tissue-Specific Analyses | Liver biopsy at 10 years post-infusion showed transcriptionally active transgene in hepatocytes without fibrosis [13] | Confirms tissue-specific persistence and safety in relevant target organs |

Several factors influence the duration and stability of transgene expression, including the target cell type (with non-dividing cells typically maintaining expression longer), the specific AAV serotype used, the design of the transgene cassette, and potential immune responses to the transgene product [11]. Promoter selection is particularly important, with tissue-specific promoters often providing more sustained expression than ubiquitously active promoters by minimizing promoter silencing and immune activation [2].

Essential Research Reagents and Materials

The following table outlines key reagents and materials essential for AAV vector research and development, particularly for studies focusing on safety and long-term expression profiles.

Table 3: Essential Research Reagents for AAV Vector Studies

| Reagent/Material | Function | Application Notes |

|---|---|---|

| HEK293 Cell Line | Producer cells; express adenoviral E1 gene essential for AAV replication [2] [9] | Widused platform; can be adapted to suspension culture for scaling |

| Transfer Plasmid (pCis) | Contains ITR-flanked transgene expression cassette [9] [14] | Cloning into ITR regions requires specialized bacterial strains (e.g., NEB Stable) |

| Packaging Plasmid (pTrans) | Provides AAV rep and cap genes in trans [9] [14] | Determines serotype and capsid properties |

| Helper Plasmid (pHelper) | Supplies adenoviral genes (E4, E2a, VA) necessary for replication [9] | Often combined with packaging plasmid in two-plasmid systems |

| AAVPureMfg Plasmids | Two-plasmid system for high-purity production [14] | Reduces prokaryotic DNA contaminants and empty capsids |

| Affinity Chromatography Resins | Purification of AAV vectors based on capsid properties [2] | Critical for removing empty capsids and process impurities |

| Digital PCR Systems | Absolute quantification of vector genome titer without standard curve [12] | More accurate than qPCR for dose determination |

| MiQuant AAV Kits | Ready-to-use kits for AAV vector genome titration [12] | Incorporates TruTiter technology to detect only intact capsids |

Experimental Protocol: Evaluating AAV Safety and Expression Durability

AAV Vector Production Using Triple Transfection Method

The following protocol describes the standard method for producing AAV vectors in research settings, with specific quality control measures to assess safety and potency attributes.

Materials and Reagents

- Cell Culture: HEK293 cells (adherent or suspension adapted) [9]

- Plasmids: Transfer plasmid (pCis), packaging plasmid (pTrans), helper plasmid (pHelper) [9] [14]

- Transfection Reagent: Polyethylenimine (PEI) or comparable transfection reagent

- Cell Culture Medium: DMEM or comparable medium supplemented with serum for adherent cultures; serum-free medium for suspension cultures

- Lysis Buffer: 50 mM Tris, 150 mM NaCl, 2 mM MgCl₂, pH 8.5, supplemented with 0.5% sodium deoxycholate and 50 U/mL benzonase

- Purification Materials: Affinity chromatography resin or iodixanol gradient solutions [2]

Production Procedure

- Cell Seeding: Seed HEK293 cells at appropriate density (e.g., 1×10⁷ cells/mL for suspension culture or 70-80% confluency for adherent culture) in complete medium [9].

- Plasmid Transfection:

- Prepare plasmid DNA mixture at molar ratio of 1:1:1 (pHelper:pTrans:pCis) [14]. For a 150 mm plate, use 10 µg of each plasmid.

- Dilute DNA mixture in opti-MEM or serum-free medium to a total volume of 1.5 mL.

- Dilute PEI transfection reagent (1 mg/mL stock) in 1.5 mL opti-MEM at a 3:1 PEI:total DNA ratio.

- Combine DNA and PEI solutions, mix thoroughly, and incubate for 15-20 minutes at room temperature.

- Add DNA-PEI complex dropwise to cells with gentle swirling.

- Harvest and Lysis:

- Harvest cells 48-72 hours post-transfection by centrifugation.

- Resuspend cell pellet in lysis buffer and incubate for 1 hour at 37°C with gentle agitation.

- Clarify lysate by centrifugation at 10,000 × g for 20 minutes.

- Purification:

- For affinity chromatography: Load clarified lysate onto AAVX or comparable affinity column. Wash with PBS containing 5-10% glycerol, then elute with elution buffer (e.g., 50 mM citrate, 500 mM NaCl, pH 2.5-3.0) and immediately neutralize [2].

- For iodixanol gradient: Layer clarified lysate on step gradient of 15%, 25%, 40%, and 60% iodixanol in PBS. Centrifuge at 350,000 × g for 2 hours. Collect the 40% fraction containing purified AAV [2].

- Formulation and Storage:

- Dialyze purified AAV against formulation buffer (PBS with 5% glycerol or comparable formulation).

- Concentrate if necessary using centrifugal filter devices.

- Aliquot and store at -80°C.

Quality Control and Characterization Assays

Rigorous quality control is essential for evaluating AAV safety and predicting in vivo performance. The following assays should be performed on purified vector preparations.

Vector Genome Titer quantification (qPCR/dPCR)

- Principle: Quantifies encapsulated vector genomes to ensure accurate dosing [12].

- Procedure:

- Treat AAV sample with DNase I (1 U/µL, 30 minutes, 37°C) to remove unencapsidated DNA.

- Inactivate DNase I by heating (65°C, 30 minutes) with EDTA.

- Digest capsid with proteinase K (0.2 mg/mL, 1 hour, 50°C).

- Perform qPCR with transgene-specific primers and compare to standard curve, or use digital PCR for absolute quantification without standard curve [12].

- Interpretation: Accurate genome titer is critical for dose determination in preclinical and clinical studies.

Capsid Titer Determination (ELISA)

- Principle: Quantifies total viral particles (both empty and full capsids) using antibodies specific to AAV capsids [2].

- Procedure:

- Coat ELISA plate with capture antibody specific to AAV serotype.

- Block with protein-based blocking buffer.

- Add AAV standards and test samples, incubate 1-2 hours.

- Add detection antibody conjugated to HRP, incubate 1 hour.

- Develop with TMB substrate, measure absorbance at 450 nm.

- Interpretation: Capsid titer combined with genome titer allows calculation of full-to-empty capsid ratio, a critical quality attribute.

Infectivity Assay (TCID₅₀ or Plaque Assay)

- Principle: Measures functional vector particles capable of transducing target cells.

- Procedure:

- Seed permissive cells (e.g., HeLa or HEK293) in 96-well plate.

- Serially dilute AAV vector in culture medium.

- Infect cells with diluted vector in the presence of adenovirus (MOI 5-10) as helper.

- After 48-72 hours, harvest cells and extract total DNA.

- Quantify vector genomes by qPCR and calculate titer in infectious units (IU)/mL.

- Interpretation: The ratio of IU/mL to vg/mL indicates specific infectivity, typically 1:100 to 1:1000 for rAAV vectors [2].

Assessing Genomic Integration (Southern Blot)

- Principle: Detects potential integration of vector sequences into host genome.

- Procedure:

- Transduce target cells with AAV vector at relevant MOI.

- Culture cells for extended period (2-4 weeks) with regular passaging.

- Extract high molecular weight genomic DNA.

- Digest DNA with restriction enzymes that cut once in vector genome.

- Perform Southern blotting using transgene-specific probe.

- Interpretation: High molecular weight bands indicate potential integration events, though rAAV predominantly persists as episomal forms [9].

Diagram 1: Comprehensive workflow for AAV vector production and quality assessment, highlighting critical steps for evaluating safety and durability.

Advanced Manufacturing: The AAVPureMfg Protocol

Recent advances in AAV manufacturing address significant impurities that can impact both safety and efficacy. The AAVPureMfg system reduces plasmid backbone encapsulation and empty capsid formation through a novel genetic design [14].

Principles and Mechanism

The AAVPureMfg system utilizes a two-plasmid approach that ensures synchronized colocalization of trans and cis constructs in producer cells [14]. The system consists of:

- pHelper-Bxb1: Provides adenoviral helper genes and the recombinase Bxb1.

- pTrans/Cis: Contains an attP/attB-flanked cis construct inserted into the 3' region of the Rep gene.

Upon co-transfection, Bxb1-mediated attP/attB recombination reconstitutes functional pTrans and generates a minicircle cis construct (mcCis) devoid of bacterial DNA sequences [14]. This design ensures that Cap expression only occurs in cells that have undergone recombination, thereby coupling capsid production with genome availability and reducing empty capsid formation.

Protocol

Materials

- Plasmids: pHelper-Bxb1 and pTrans/Cis [14]

- HEK293 cells (adherent or suspension)

- Transfection reagent (PEI or commercial alternative)

- Standard cell culture and purification materials as in Section 5.1.1

Procedure

- Cell Seeding: Seed HEK293 cells at appropriate density as in standard protocol.

- DNA Transfection:

- Prepare DNA mixture at 1:1 mass ratio (pHelper-Bxb1:pTrans/Cis).

- For a 150 mm plate, use 20 µg total DNA (10 µg of each plasmid).

- Complex with PEI at 3:1 ratio as previously described.

- Add to cells with gentle mixing.

- Harvest and Purification: Follow same procedures as in Section 5.1.2.

- Quality Control: Perform standard QC assays with emphasis on:

- Plasmid backbone contamination: Quantify by qPCR with primers specific to bacterial sequences.

- Full-to-empty ratio: Analyze by analytical ultracentrifugation or charge-detection mass spectrometry.

Expected Results

Compared to standard triple transfection, AAVPureMfg typically achieves:

- 10- to 50-fold reduction in prokaryotic DNA contaminants [14]

- Up to threefold improvement in full capsid ratio at harvest [14]

- Reduced plasmid demand while maintaining or improving vector yields

Challenges and Future Directions

Despite the considerable advantages of AAV vectors, several challenges remain in their clinical application. Immunogenicity concerns persist, particularly regarding pre-existing neutralizing antibodies in patient populations and cell-mediated immune responses to capsid antigens [11] [8]. The limited packaging capacity of AAV (approximately 4.7 kb) constrains the size of therapeutic genes that can be delivered, necessitating strategies such as trans-splicing dual vectors for larger genes [8]. Manufacturing complexities contribute to high costs, with therapies like Zolgensma and Hemgenix priced at $2.1 million and $3.5 million per dose, respectively [11].

The field is actively addressing these limitations through multiple innovative approaches. Capsid engineering through rational design, directed evolution, and computational modeling is generating novel variants with enhanced tissue specificity and reduced immunogenicity [10] [15]. Advanced manufacturing platforms like AAVPureMfg are addressing impurity concerns at the production level [14]. Emerging alternative platforms, including lipid nanoparticles (LNPs) and herpes simplex virus (HSV-1) vectors, are being explored for applications where AAV faces limitations, though AAV remains the dominant platform for in vivo gene therapy [11].

As the field progresses, the focus is shifting toward precision targeting to reduce systemic exposure, optimized promoter systems for regulated transgene expression, and improved manufacturing efficiency to enhance accessibility. With continued refinement and innovation, AAV vectors are poised to maintain their central role in the advancing landscape of gene therapy, potentially offering cures for an expanding range of genetic disorders.

Application Notes

Adeno-associated virus (AAV) vectors have emerged as a leading platform for in vivo gene therapy, with over 2,000 therapies in clinical development [16]. However, their path to commercial success is fraught with significant manufacturing hurdles. This document details the core challenges of packaging capacity, immunogenicity, and scalability, providing data-driven insights and practical protocols to guide researchers and drug development professionals in navigating the complex AAV manufacturing landscape.

Challenge: Limited Packaging Capacity

The inherently small size of the AAV capsid imposes a strict limit on the size of the genetic payload it can carry, which is a major constraint for therapies targeting large genes.

The Packaging Limit Barrier: While the wild-type AAV genome is approximately 4.7 kb, research indicates that recombinant AAV (rAAV) can physically package genomes up to 6.0 kb [17]. However, transduction efficiency significantly decreases for genomes larger than 5.2 kb. One study found that vectors with genomes of 5.3 kb and higher transduced cells less efficiently (within a log) than those with wild-type-sized genomes [17]. This creates a practical optimal packaging capacity of around 5.2 kb for most applications, which includes the transgene, promoter, polyadenylation signal, and other regulatory elements, all of which must fit between the two Inverted Terminal Repeats (ITRs) [9].

Underlying Mechanism and a Solution: The reduction in transduction efficiency for oversized genomes is not due to an inability to package, but rather a post-entry block. Virions containing larger-than-wt genomes are preferentially degraded by the proteasome [17]. This block can be overcome, as treatment of transduced cells with proteasome inhibitors can increase transduction to wild-type levels [17].

Table 1: Impact of Recombinant AAV Genome Size on Transduction Efficiency

| Genome Size | Packaging Efficiency | Transduction Efficiency | Notes |

|---|---|---|---|

| 4.1 - 4.9 kb | Efficient | High (Baseline) | Considered the optimum size for AAV2 vectors [17]. |

| ~5.2 kb | Efficient | Moderate | Often cited as a practical upper limit for effective gene therapy. |

| ≥5.3 kb | Efficient | Reduced (up to 1-log) | Preferentially targeted for proteasomal degradation [17]. |

| Up to 6.0 kb | Possible | Significantly Reduced | Demonstration of physical packaging limit; requires mitigation strategies [17]. |

The following diagram illustrates the cellular fate of AAV vectors with standard versus oversized genomes, highlighting the critical role of the proteasome.

Challenge: Host Immunogenicity

Immunogenicity remains a critical barrier to safe and effective AAV gene therapy, capable of diminishing therapeutic efficacy and causing adverse events.

The Dual Components of Immune Response: The immune system can mount responses against both the AAV capsid and the transgene product [18]. Pre-existing neutralizing antibodies (NAbs) from natural AAV exposure can prevent initial transduction, while cell-mediated cytotoxic T-cell responses against the capsid can lead to the clearance of transduced cells [18].

Innate Immune Sensing: The initial innate immune response is a key driver of subsequent adaptive immunity. AAV vectors are sensed as foreign through various Pattern Recognition Receptors (PRRs):

- TLR9 in endosomes recognizes unmethylated CpG motifs in the AAV single-stranded DNA genome [18].

- cGAS, a cytosolic DNA sensor, can be activated by the AAV genome or by mitochondrial DNA released due to cellular stress from transduction [18].

- TLR2 on the cell surface can be activated by empty AAV capsids [18]. This sensing triggers signaling cascades (e.g., NF-ĸB, IRF) that lead to the production of type I interferons and pro-inflammatory cytokines, creating an environment that promotes adaptive immune responses.

The following diagram outlines the key pathways in AAV immunogenicity.

Challenge: Scalability and Manufacturing

The transition from small-scale research production to commercial-scale manufacturing of AAV vectors is a major bottleneck, characterized by complex processes, low yields, and high costs.

The Scalability Bottleneck: Most viral vectors are still produced using transient transfection of HEK293 cells with multiple plasmids, a process that is inherently inefficient, variable, and relies on large amounts of costly plasmid DNA [19]. Downstream purification is equally challenging, often involving customized protocols with poor recovery rates that further drive up the cost of goods [19].

Trends in Manufacturing Innovation: The industry is actively pursuing solutions to overcome these hurdles:

- Moving to Producer Cell Lines: Packaging and producer cell lines, which stably express the necessary viral components, eliminate the need for large-scale plasmid DNA and transfection reagents for every batch. This shift can immediately cut manufacturing expenses by approximately 35% and enable additional savings of up to ~90–100% through higher titers and improved full capsid ratios [20].

- Suspension Bioreactor Systems: Shifting from adherent culture in multilayer vessels to suspension-based bioreactors is critical for closed, automated, and scalable commercial GMP operations [19] [20].

- Synthetic DNA: Replacing plasmid DNA produced by bacterial fermentation with enzymatically produced synthetic DNA avoids bacterial contaminants, shortens production timelines, and reduces costs [19].

- Advanced Formulation: AAV vectors are fragile and susceptible to aggregation, capsid disassembly, and genome ejection. Developing stable liquid or lyophilized (freeze-dried) formulations for storage at 2-8°C, rather than deep-freezing (below -60°C), is a major focus to simplify logistics and global distribution [21].

Table 2: Key Manufacturing Platforms and Their Impact on Scalability

| Manufacturing Approach | Key Features | Impact on Cost & Scalability | Examples/Notes |

|---|---|---|---|

| Transient Transfection | Triple plasmid transfection in HEK293 cells; high plasmid DNA need. | High COGs; difficult to scale; significant batch-to-batch variability. | Current industry standard but inefficient [19]. |

| Stable Producer Cell Lines | Engineered cells for stable virus component expression. | Reduces plasmid needs by ~35%; potential for 90-100% cost reduction via higher yields [20]. | SK pharmteco's platform [20]. |

| Baculovirus/Sf9 System | Uses insect Sf9 cells; scalable. | Scalable production; different host system [9]. | An alternative to mammalian systems [9]. |

| Synthetic DNA | Enzymatically produced; no bacterial fermentation. | Reduces cost and time; eliminates bacterial impurities [19]. | Complementary strategy to stable cell lines. |

The following workflow summarizes a modern, scalable AAV manufacturing process.

Experimental Protocols

Protocol 1: Assessing Packaging Capacity and Transduction of Oversized Genomes

This protocol is adapted from a foundational study on AAV packaging capacity [17].

1. Objective: To produce and characterize rAAV vectors with genomes exceeding 5.0 kb and evaluate the effect of proteasome inhibition on their transduction efficiency.

2. Materials

- Plasmids: pAVCNst packaging cassettes or similar, with inserts to generate recombinant genomes ranging from 4.4 to 6.0 kb [17].

- Helper Plasmids: AAV helper plasmids (e.g., pXR1-5 for various serotypes) and adenovirus helper plasmid.

- Cells: HEK293, HeLa, or COS-1 cells.

- Reagents: Transfection reagent, Dulbecco’s Modified Eagle's Medium (DMEM) with 10% FBS, proteasome inhibitor (e.g., MG132).

3. Methodology

- Vector Production: Transfect HEK293 cells in triplicate with the transfer plasmid (containing the oversized genome), AAV helper plasmid, and adenovirus helper plasmid using a standard calcium phosphate or PEI method.

- Purification: 48-72 hours post-transfection, harvest cells and lysate. Purify vectors via iodixanol gradient centrifugation or affinity chromatography.

- Dot Blot Analysis (Packaging Efficiency):

- Treat purified vector samples with DNase I to remove unencapsidated DNA.

- Inactivate DNase I, then degrade the capsid with Proteinase K.

- Denature the released DNA and spot onto a nitrocellulose or nylon membrane.

- Hybridize with a radiolabeled or digoxigenin-labeled probe complementary to the transgene.

- Quantify the signal to determine the relative quantity of packaged DNA for each vector preparation.

- Transduction Assay:

- Plate target cells (e.g., HeLa) in 24-well plates.

- Pre-treat cells in a subset of wells with a proteasome inhibitor (e.g., 5-10 µM MG132) for 2-4 hours.

- Transduce all wells with an equal genomic titer (e.g., 1x10^4 vg/cell) of the different-sized AAV vectors, maintaining the MG132 in the pre-treated wells.

- 48-72 hours post-transduction, harvest cells and assay for transgene expression (e.g., CAT assay, fluorescence, or luciferase activity).

4. Data Analysis: Compare the transgene expression levels from vectors of different sizes, with and without proteasome inhibitor treatment. Expect to see a recovery of transduction efficiency for oversized genomes (>5.2 kb) in the presence of the inhibitor.

Protocol 2: Immunogenicity Assay for Detecting Pre-existing Neutralizing Antibodies (NAbs)

This protocol outlines the development of a cell-based NAb assay, which is often required for patient screening in clinical trials [22].

1. Objective: To detect and quantify pre-existing neutralizing antibodies in human serum that inhibit AAV transduction.

2. Materials

- Reporter Vector: AAV vector of the desired serotype encoding an easily quantifiable reporter gene (e.g., GFP, luciferase).

- Cell Line: A cell line permissive to the AAV serotype (e.g., HEK293 for AAV2).

- Test Samples: Human serum or plasma samples.

- Controls: A known positive control (serum with anti-AAV antibodies) and a negative control (serum from naive individuals or assay buffer).

3. Methodology

- Serum Heat-Inactivation: Heat-inactivate all serum samples at 56°C for 30 minutes to degrade complement proteins.

- Sample Dilution: Prepare serial dilutions of the test and control sera in cell culture medium.

- Virus-Serum Incubation:

- Mix a fixed titer of the reporter AAV vector (sufficient to give a robust signal in the absence of serum) with an equal volume of each serum dilution.

- Incubate the virus-serum mixtures at 37°C for 1 hour to allow antibodies to bind the virus.

- Transduction:

- Apply the virus-serum mixtures to pre-seeded cells. Include a "virus-only" control (no serum) to define 100% transduction.

- Incubate for 48-72 hours.

- Signal Quantification: Measure reporter gene expression (e.g., fluorescence intensity for GFP, luminescence for luciferase).

4. Data Analysis and Cutpoint Determination

- Calculate the percentage neutralization for each sample:

% Neutralization = [1 - (Signal Sample / Signal Virus-only)] * 100. - For a qualitative (positive/negative) assay, establish a cutpoint using naive serum samples. The cutpoint is typically set as the mean % neutralization of naive sera plus 2 or 3 standard deviations. Samples exceeding this cutpoint are considered positive for NAbs.

- For a semi-quantitative assay, report the titer, often defined as the dilution at which 50% neutralization (ND50) is achieved.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Reagents for AAV Manufacturing and Characterization Research

| Reagent / Material | Function | Key Considerations |

|---|---|---|

| Transfer Plasmid | Contains the transgene of interest flanked by AAV ITRs. | The backbone should be propagated in recombination-deficient bacterial strains (e.g., NEB Stable) to maintain ITR integrity [9]. |

| Packaging Plasmid (Rep/Cap) | Provides the AAV Rep and Cap genes in trans. | Determines the serotype and tropism of the produced vector. Can be wild-type or engineered (e.g., AAV-DJ) [9]. |

| Helper Plasmid | Provides essential adenoviral genes (E4, E2a, VA) for AAV replication. | Often combined with the packaging plasmid in simpler systems [9]. |

| HEK293T Cells | Production cell line. | Expresses the adenovirus E1 gene, which is critical for AAV replication when using standard helper plasmids [9]. |

| Proteasome Inhibitor (e.g., MG132) | Used in research to block proteasomal degradation of viral particles. | Can enhance transduction, particularly for vectors with oversized genomes [17]. For research use only. |

| Stable Producer Cell Line | Cell line engineered to stably express all AAV components. | Eliminates need for transfection and bulk plasmids; improves scalability and consistency; reduces costs [20]. |

| Polysorbate 80 / Poloxamer 188 | Surfactants used in formulation buffers. | Reduce aggregation and surface adsorption of AAV particles during storage and handling [21]. |

| Trehalose / Sucrose | Stabilizing excipients. | Act as cryoprotectants and lyoprotectants, helping to maintain capsid integrity during freezing, thawing, and lyophilization [21]. |

| Reporter Vector (e.g., AAV-GFP) | AAV vector encoding a fluorescent or luminescent protein. | Essential for titrating functional virus and for conducting neutralization assays [22]. |

Adeno-associated virus (AAV) has emerged as a leading viral vector for human gene therapy due to its favorable safety profile, non-pathogenic nature, and ability to transduce a wide range of tissues with long-term transgene expression [23] [24]. The AAV virion is a small, non-enveloped particle with an icosahedral capsid approximately 25 nm in diameter, containing a linear single-stranded DNA genome of about 4.7 kb [2] [24]. The AAV genome is flanked by inverted terminal repeats (ITRs) that serve as origins of replication and packaging signals, while the coding sequence consists of Rep genes (required for replication) and Cap genes (encoding capsid proteins) [24]. For recombinant AAV (rAAV) vectors used in gene therapy, the Rep and Cap genes are replaced by the therapeutic transgene expression cassette, retaining only the ITRs which are necessary for genome packaging [2].

AAV vectors are particularly valuable for neuroscience research and clinical applications because they efficiently transduce neurons, cause minimal immunoreactivity compared to other viral vectors, and have minimal impact on basal cell function [24]. A key advantage is their ability to persist in non-dividing cells as circular episomes for years, enabling long-term transgene expression without genomic integration, though random integration can occur at low frequencies [24]. The primary limitation of AAV is its limited packaging capacity of approximately 4.7-5.0 kb, though strategies like dual or triple AAV co-infection with split genes can overcome this constraint [24].

Natural AAV Serotypes and Their Tissue Tropisms

To date, thirteen natural serotypes of AAV have been identified, each with distinct capsid structures that confer different tissue tropisms and transduction efficiencies [2] [24]. These differences arise from variations in the VP3 capsid protein sequence, which dictates interactions with host cell surface receptors and determines tissue specificity and immunogenicity [2]. The table below summarizes the key characteristics and primary tropisms of the most widely used natural AAV serotypes.

Table 1: Natural AAV Serotypes and Their Tissue Tropisms

| Serotype | Primary Receptor(s) | Tissue/System Tropism | Key Applications and Notes |

|---|---|---|---|

| AAV1 | α2,3 and α2,6 N-linked sialic acid [25] | Skeletal muscle, heart, CNS | Efficient transduction in mouse skeletal muscle and human skeletal muscle [25]; Used in cardiac gene transfer [25] |

| AAV2 | Heparan sulfate proteoglycan [2] | CNS, liver, kidney, retina | Most extensively characterized serotype; Natural neuronotropism [24]; Used in Allen Mouse Brain Connectivity Atlas [24] |

| AAV4 | α2-3 O-linked sialic acid [25] | CNS, retina | Requires sialic acid binding for transduction [25] |

| AAV5 | α2-3 N-linked sialic acid [25] | CNS, lung, retina, pancreas | Requires sialic acid binding for transduction [25]; Efficient transduction of airway epithelial cells [25] |

| AAV6 | α2,3 and α2,6 N-linked sialic acid; Heparin sulfate [25] [2] | Skeletal muscle, heart, lung | Efficient transduction of airway epithelial cells in mouse lungs [25]; Infects epithelial cells and cardiomyocytes well in vitro [2] |

| AAV7 | Not specified | Liver, skeletal muscle, retina | Cardiac gene transfer [25] |

| AAV8 | Laminin receptor [26] | Liver, skeletal muscle, retina, pancreas | Cardiac gene transfer [25]; Efficient in pancreatic beta and alpha cells [25] |

| AAV9 | Laminin receptor [26] | Heart, CNS, liver, skeletal muscle, pancreas | Superior global cardiac gene transfer in mouse and rat [25]; Crosses blood-brain barrier [25] |

| AAV11 | Not specified | Projection neurons, astrocytes | Enables efficient retrograde targeting of projection neurons and enhances astrocyte-directed transduction [25] |

The tropism differences between serotypes are primarily determined by their interactions with specific cell surface receptors. For instance, AAV2 binds to heparan sulfate proteoglycan, while AAV4 and AAV5 require sialic acid binding for transduction, albeit with different linkage specificities [25] [2]. AAV1 and AAV6 both utilize N-linked sialic acid for cell entry [25]. Recent research has identified an alternate receptor for adeno-associated viruses, expanding our understanding of AAV entry mechanisms [25].

Engineering AAV Capsids: Rational Design, Directed Evolution, and Machine Learning

While natural AAV serotypes provide a valuable toolkit for gene delivery, they have limitations including suboptimal transduction efficiency, pre-existing immunity in human populations, and inadequate tissue specificity for many therapeutic applications [1] [26]. To address these challenges, researchers have developed three primary approaches for engineering novel AAV capsids: rational design, directed evolution, and machine learning-guided engineering.

Rational Design

Rational design leverages structural insights from AAV capsids and their interactions with host factors to make targeted modifications that enhance specific properties [1] [26]. This approach requires detailed understanding of AAV biology, including:

- Receptor binding domains: Modifying surface-exposed variable regions to alter receptor binding specificity

- Antigenic epitopes: Mutating residues that are targets for neutralizing antibodies to evade pre-existing immunity

- Phosphorylation sites: Engineering surface-exposed tyrosine residues to reduce ubiquitination and enhance intracellular trafficking

The rational design process begins with structural analysis of capsid-receptor interactions, followed by targeted amino acid substitutions or insertions of peptide ligands, and finally validation of novel capsids in relevant models.

Directed Evolution

Directed evolution applies selective pressure to diverse AAV capsid libraries to identify variants with enhanced properties [1] [26]. This approach involves:

- Library creation through DNA shuffling of cap genes from multiple serotypes, error-prone PCR, or peptide display

- Selection in vitro (on cell lines) or in vivo (in animal models)

- Recovery and amplification of AAV variants that successfully transduce target tissues

- Iterative cycles of selection to enrich for capsids with desired traits

Directed evolution has generated novel AAV variants with enhanced tropism for specific tissues, including the central nervous system, retina, and liver.

Machine Learning-Guided Engineering

Machine learning (ML) represents the cutting edge of AAV capsid engineering, using computational analysis of high-throughput screening data to enable predictive design [1] [26]. ML approaches:

- Analyze large datasets from directed evolution experiments

- Identify sequence-function relationships that would be difficult to detect manually

- Generate predictive models to forecast the properties of novel capsid sequences

- Guide the design of focused capsid libraries with higher probabilities of success

The integration of these three approaches—rational design, directed evolution, and machine learning—creates a powerful engineering pipeline that accelerates the development of novel AAV capsids with optimized properties for specific therapeutic applications [1] [26].

Figure 1: Integrated approaches for engineering novel AAV capsids, combining rational design, directed evolution, and machine learning methodologies.

Experimental Protocols for AAV Serotype Evaluation

Protocol: In Vivo Evaluation of AAV Serotype Tropism

Objective: Systematically compare the transduction efficiency and tissue tropism of different AAV serotypes in a murine model.

Materials:

- Purified AAV vectors (serotypes to be tested) expressing a reporter gene (e.g., eGFP, luciferase)

- Experimental animals (e.g., C57BL/6 mice)

- Sterile PBS for dilutions

- Appropriate injection equipment (syringes, needles, stereotactic apparatus for CNS injections)

- Tissue collection supplies (dissection tools, cryostat, fixation reagents)

Procedure:

- Vector Preparation: Dilute all AAV serotypes to the same genomic titer (e.g., 1×10^12 vg/mL) in sterile PBS. Maintain samples on ice until administration.

- Animal Administration: Administer AAV vectors to animals via the intended route (intravenous, intramuscular, intracerebral, etc.). Include a PBS-injected control group.

- Incubation Period: Allow 2-4 weeks for transgene expression to reach peak levels.

- Tissue Collection: Euthanize animals and harvest target tissues (brain, liver, heart, skeletal muscle, etc.).

- Analysis:

- Imaging: Capture fluorescence images of whole tissues and sectioned samples

- Histology: Process tissues for immunohistochemistry and fluorescence microscopy

- Molecular analysis: Extract DNA/RNA for qPCR analysis of vector biodistribution and transgene expression

- Quantification: Quantify transduction efficiency by counting reporter-positive cells or measuring reporter activity in tissue extracts.

Protocol: Assessing Neutralizing Antibody Activity Against AAV Serotypes

Objective: Evaluate the prevalence of pre-existing neutralizing antibodies against different AAV serotypes in human serum samples.

Materials:

- HEK293 or HeLa cells

- AAV vectors expressing reporter genes (e.g., luciferase)

- Test serum samples

- Control serum (AAV-negative)

- Cell culture media and reagents

- Luciferase assay system

Procedure:

- Serum Heat-Inactivation: Heat-inactivate all serum samples at 56°C for 30 minutes to eliminate complement activity.

- Serial Dilution: Prepare serial dilutions of test and control sera in cell culture medium.

- Virus-Serum Incubation: Mix AAV vectors (1×10^9 vg) with equal volumes of diluted serum and incubate at 37°C for 1 hour.

- Cell Infection: Add virus-serum mixtures to cells and incubate for 48-72 hours.

- Reporter Assay: Measure reporter gene expression (e.g., luciferase activity).

- Data Analysis: Calculate neutralizing antibody titers as the serum dilution that inhibits 50% of reporter gene expression compared to control serum.

AAV Capsid Engineering Workflow

Figure 2: Directed evolution workflow for engineering novel AAV capsids with enhanced properties.

Essential Research Reagents for AAV Studies

Table 2: Essential Research Reagents for AAV Serotype and Capsid Engineering Studies

| Reagent/Category | Specific Examples | Function/Application |

|---|---|---|

| AAV Serotypes | AAV1, AAV2, AAV5, AAV6, AAV8, AAV9, AAV11 [25] | Comparative tropism studies; Baseline for engineering |

| Cell Lines | HEK293, HEK293T, HeLa, Sf9 (for baculovirus system) [2] | AAV production; Transduction efficiency assays |

| Plasmids | pAAV-RC (rep/cap), pHelper, pAAV-GOI (gene of interest) [2] | AAV vector production; Provides essential viral genes |

| Promoters | CAG, CBA, CMV, Synapsin, GFAP, MECP2 [2] [24] | Drive transgene expression; Constitutive vs. cell-specific |

| Reporter Genes | eGFP, mCherry, LacZ, Luciferase [24] | Visualize and quantify transduction efficiency |

| Detection Antibodies | Anti-AAV VP1/2/3, Anti-GFP, Cell type-specific markers [2] | Characterize vector distribution and cell tropism |

| Quantitative Assays | qPCR/ddPCR, ELISA, Western Blot, Immunohistochemistry [2] | Measure genome titers, protein expression, localization |

| Animal Models | Mice, Rats, Non-human primates [25] [24] | In vivo tropism and efficacy studies |

AAV Vector Manufacturing Considerations

The manufacturing process significantly influences AAV vector characteristics and performance. Current platforms include mammalian cell systems (HEK293-based) and baculovirus-insect cell systems, each generating vectors with distinct molecular signatures that affect purity, safety, and potency [2]. A critical challenge in AAV manufacturing is the production of capsids that either lack DNA cargo or contain partial genomes, with state-of-the-art processes typically achieving full/empty ratios of only 8-30% [2].

Key titration metrics for AAV characterization include:

- Capsid titer (cp/mL): Total fully assembled capsids, measured by ELISA

- Genome titer (vg/mL): Vector genomes available for transduction, measured by qPCR after DNase treatment

- Infectious titer (IU/mL): Biologically active vectors, measured by in vitro assays

These parameters collectively determine vector quality and dosing considerations, particularly for systemic administration where empty capsids can contribute to immunogenicity without therapeutic benefit [2].

The AAV serotype landscape has evolved from a collection of naturally occurring variants to an expanding toolkit of engineered capsids with refined properties for specific research and therapeutic applications. Understanding the natural tropisms of AAV serotypes provides a foundation for selecting appropriate vectors for specific targets, while capsid engineering approaches—including rational design, directed evolution, and machine learning—enable the development of novel vectors with enhanced transduction efficiency, reduced immunogenicity, and improved tissue specificity. As these technologies continue to mature alongside advances in vector manufacturing, AAV-based gene therapies will become increasingly targeted and effective for treating a broad range of human diseases.

The AAV Production Workflow: From Plasmid to Purified Drug Product

The growing demand for recombinant adeno-associated virus (rAAV) vectors in gene therapy has exposed significant bottlenecks in traditional manufacturing processes, which are often limited by volumetric productivity and scalability [27]. Upstream process intensification represents a critical strategy to overcome these limitations, with high cell density (HCD) transfection in bioreactors emerging as a promising solution. This application note details the implementation of an intensified upstream process utilizing high-density transient transfection of HEK293 cells in perfusion mode bioreactors. The protocol demonstrates the feasibility of transfecting cells at densities of 50 million cells/mL (MVC/mL) and maintaining cultures at ≥30 MVC/mL throughout production, achieving rAAV production levels per cell comparable to traditional shake flask cultures at standard densities (1 MVC/mL) [27]. This approach offers the potential to significantly enhance rAAV volumetric production capacity to meet the growing demands for gene therapies.

Key Experimental Data and Performance Metrics

The table below summarizes the key quantitative outcomes from implementing high-density transfection in a perfusion bioreactor system compared to a standard shake flask process.

Table 1: Performance Comparison of Intensified vs. Standard AAV Production Processes

| Process Parameter | Standard Shake Flask Process | Intensified Perfusion Bioreactor Process | Improvement/Fold Change |

|---|---|---|---|

| Viable Cell Density at Transfection | 1 - 2 MVC/mL [27] | 50 MVC/mL [27] | 25-50x |

| Culture Maintenance Density | 1 - 2 MVC/mL | ≥ 30 MVC/mL [27] | 15-30x |

| rAAV9 Volumetric Yield | 10^12 - 10^15 vg/L [27] | Comparable cell-specific productivity achieved at HCD [27] | Maintained productivity at significantly higher volume |

| Process Scalability | Limited by surface area/gas exchange | High; demonstrated in 200 mL STR, scalable principle [27] [28] | Significant improvement |

| Production Time | Reference (7.5x longer than Quantum BR) [28] | Reduced (Up to 7.5x reduction vs. stack systems) [28] | Up to 7.5x reduction |

| Cost of Goods (COGs) | Reference (20.7x higher than Quantum BR) [28] | Reduced (Up to 20.7x reduction vs. CellSTACK) [28] | Substantial reduction |

The data demonstrates that process intensification via HCD perfusion culture enables a dramatic increase in production capacity while maintaining product quality and reducing operational costs and timelines.

Detailed Experimental Protocol

Materials and Reagent Solutions

The following table lists the critical reagents and their functions essential for establishing a high-density transfection process.

Table 2: Essential Research Reagent Solutions for High-Density Transfection

| Reagent / Material | Function / Role in the Process | Specific Examples / Notes |

|---|---|---|

| HEK293 Cell Line | Host cell for rAAV production via transient transfection. | HEK293F, Viral Production Cell 2.0 (VPC2) [27]. |

| Plasmids | Provide genetic components for rAAV assembly: genome (GOI), rep/cap, and adenoviral helper functions. | pHelper, pGFP (or other GOI), pRC (serotype-specific, e.g., pR2C9 for AAV9) [27]. A 1:1:2 ratio is common. |

| Transfection Reagent | Facilitates DNA delivery into cells by forming polyplexes. | Polyethylenimine (PEI MAX) is cost-effective for large-scale use [27]. |

| Culture Media | Supports cell growth, viability, and protein expression. | Chemically defined media like BalanCD HEK293, FreeStyle 293, or Viral Production Medium [27]. |

| Perfusion Bioreactor System | Provides a controlled environment for HCD culture with continuous medium exchange and waste removal. | DASBOX bioreactor equipped with an ATF-2 (Alternating Tangential Flow) system for cell retention [27]. |

| Lysis Buffer | Releases packaged rAAV vectors from the cell pellet after harvest. | 50 mM Tris, 150 mM NaCl, 2 mM MgCl2, followed by freeze-thaw cycles [27]. |

Step-by-Step Workflow Protocol

Part I: Pre-culture and Bioreactor Inoculation

- Cell Maintenance: Maintain HEK293F cells in suspension culture using appropriate media (e.g., BalanCD HEK293) in Erlenmeyer flasks or spin tubes. Keep cells in an exponential growth phase in an incubator at 37°C, 5% CO2 with agitation [27].

- Bioreactor Setup & Inoculation: Inoculate a stirred-tank bioreactor (e.g., DASBOX) with cells in the exponential growth phase. The system should be equipped with an ATF-2 device connected to a hollow fiber cartridge (e.g., 0.2 µm pore size, 88 cm² surface area) for cell retention [27].

- Cell Densification: Before transfection, increase the cell density to the target of 50 MVC/mL. This is achieved by retaining cells via the ATF system while performing medium exchanges, or by centrifuging and resuspending the cell pellet in a smaller volume of fresh medium in the case of pseudo-perfusion spin tubes [27].

Part II: Transfection at High Cell Density

- Preparation of DNA-PEI Complexes (Polyplexes):

- DNA Mix: Dilute the three plasmids (pRC, pGOI, pHelper) in a transfection medium (e.g., glucose-free BalanCD) to a total volume of 1 mL per 50 million cells. A typical ratio is 1:1:2, using 1 µg of total plasmid DNA per 1 million cells [27].

- PEI Mix: Dilute PEI MAX in the same transfection medium to a concentration of 2 µg per 1 million cells, in a volume equal to the DNA mix [27].

- Complexation: Combine the DNA and PEI solutions by pipetting. Vortex immediately and incubate at room temperature for 10-15 minutes to allow polyplex formation.

- Transfection: Add the formed polyplexes directly to the bioreactor culture running at 50 MVC/mL. Ensure gentle mixing to distribute the complexes homogeneously throughout the vessel. This point is defined as 0 hours post-transfection (hpT) [27].

Part III: Perfusion Production and Harvest

- Post-Transfection Perfusion: After transfection, initiate or continue perfusion mode to maintain the culture environment. A perfusion rate that sustains a viable cell density of ≥30 MVC/mL throughout the production phase is critical. The hollow fiber filter retains cells and AAV particles while removing waste metabolites and supplying fresh nutrients [27].

- Harvest: At 72 hpT, terminate the production run. Harvest the bioreactor contents by centrifugation (e.g., 200 × g for 5 minutes) to separate the cell pellet from the spent culture medium. The primary yield of rAAV is contained within the cell pellet. Store the supernatant and cell pellet at -80°C for subsequent analysis and purification [27].

- Cell Lysis and Clarification: Thaw the cell pellet and resuspend it in lysis buffer. Perform three cycles of freeze-thaw by alternating between an isopropanol bath (-80°C) and a water bath (37°C). Centrifuge the lysate (3000 × g, 4°C, 10 minutes) to remove cellular debris. The resulting supernatant contains the crude rAAV vector for downstream purification and analytics [27].

The following diagram illustrates the core workflow of this intensified process.

Downstream Considerations and Analytical Methods

Successful upstream intensification necessitates complementary downstream processing and analytical techniques capable of handling the increased product titers and ensuring quality.

Downstream Processing: The full/empty capsid ratio is a critical quality attribute (CQA) for AAV products [29]. As upstream titers increase, traditional anion-exchange chromatography (AEX) with linear gradients can become a bottleneck due to limited loading capacity (~2e13-2e14 cp/mL) [30]. Weak Partitioning AEX combined with isocratic elution has been demonstrated as a superior, next-generation purification step. This method can load >1e15 cp/mL, achieving >80% full capsid purity and >80% genomic yields while reducing processing time by 10-fold compared to standard linear gradient AEX [30].

Analytical Techniques for Capsid Content: Accurate quantification of full and empty capsids is essential for process control and product release. The table below compares key analytical methods.

Table 3: Comparison of Analytical Methods for AAV Capsid Content

| Analytical Method | Measured Attribute | Key Advantages | Key Limitations |

|---|---|---|---|

| dFLISA [31] | Capsid titer and genome titer simultaneously in one assay. | High precision/accuracy; suitable for crude and purified samples; amenable to validation. | Newer method, requires specific reagents (e.g., anti-AAV VHH antibody). |

| AUC-SV [29] | Buoyant density (empty vs. full). | Resolves empty, full, and intermediate species; considered a gold standard. | Low throughput; requires significant sample purification and expertise. |

| CDMS [29] | Mass of individual capsids. | Single-particle analysis; can distinguish between different populations. | Specialized, less widely available instrumentation. |

| SEC-MALS [29] | Size and light scattering. | Provides information on size and aggregation. | May have limited resolution for closely related species. |

| qPCR/dPCR + ELISA [32] [31] | Genome titer (PCR) and capsid titer (ELISA). | Widely used, orthogonal methods. | Prone to variability as two separate assays on different samples [31]. |

The relationship between upstream intensification, downstream processing, and analytics in the context of overall AAV manufacturing is summarized below.

This application note establishes a robust protocol for the intensification of rAAV upstream production using high cell density transfection in perfusion bioreactors. By enabling transfection at 50 MVC/mL and maintaining culture at high densities, this process significantly increases volumetric productivity while reducing operational costs and timelines. The implementation of this intensified approach, coupled with modern downstream purification and analytical techniques like weak partitioning AEX and dFLISA, provides a comprehensive solution to the current manufacturing bottlenecks, facilitating the advancement and scalability of AAV-based gene therapies.

Recombinant adeno-associated virus (rAAV) has emerged as a leading platform for in vivo gene delivery, underpinning a new class of therapeutics for genetic and rare diseases [33] [34]. The successful development and commercialization of these therapies are critically dependent on the foundational elements of production: plasmid design and critical raw materials. These starting materials dictate not only the yield and cost of the final product but also its safety, efficacy, and quality [35] [36]. Current good manufacturing practice (cGMP) production of rAAV faces significant challenges, including low yields, difficult scalability, and high levels of process-related impurities, which often originate from the initial selection and quality of plasmids and other raw materials [33] [34] [36]. This document details the critical considerations for plasmid design and raw material selection, providing structured protocols to establish a robust foundation for high-yielding rAAV manufacturing processes aimed at researchers and drug development professionals.

Plasmid Design Systems for rAAV Production

The choice of plasmid system is a primary determinant in the efficiency, yield, and purity of rAAV production. The field is transitioning from traditional multi-plasmid systems toward more innovative and consolidated designs to overcome inherent limitations of scalability and consistency.

Traditional and Emerging Plasmid Systems

The table below compares the primary plasmid systems used in rAAV manufacturing.

Table 1: Comparison of Plasmid Systems for rAAV Production

| System Type | Key Components & Description | Key Advantages | Reported Yields & Performance | Key Challenges |

|---|---|---|---|---|

| Triple Plasmid Transfection [33] | Three separate plasmids:- Vector genome (pAAV)- Rep/Cap (pRC)- Adenovirus helper (pHelper) | - Flexibility for different serotypes/transgenes.- Shorter timeline than stable cell lines.- Well-established history in clinical manufacturing [33]. | - Yields often >105 vg/cell in crude lysates [33].- Volumetric yields of ~1014 vg/L at bench scale, potentially >1015 vg/L in high-density processes [27]. | - High plasmid DNA cost (>$500,000 for a 500L batch) [19].- Requires fine-tuning of plasmid ratios.- Significant batch-to-batch variability.- High levels of plasmid-derived impurities (e.g., bacterial DNA) [37] [19]. |

| Single Plasmid (AAVone) [37] | Single plasmid consolidating:- AAV vector genome- Rep/Cap genes- Adenovirus helper genes | - 2- to 4-fold increase in yields vs. triple transfection.- Low batch-to-batch variation.- Simplified production process.- Reduced DNA impurities and non-functional genomes [37]. | - Achieves favorable full-to-empty capsid ratios.- Requires significantly less DNA for transfection. | - Upfront development and characterization.- Larger plasmid size may present handling challenges. |

| Synthetic DNA [19] | Enzymatically produced DNA fragments replacing traditional plasmid DNA. | - Eliminates bacterial fermentation and associated impurities (endotoxins, host-cell DNA).- Shorter production timelines.- Can be precisely tailored for efficiency. | - Reduces total DNA mass required for transfection.- Enables higher transfection efficiency. | - Technology is still gaining maturity for large-scale GMP application.- Requires re-development of existing processes. |

Plasmid Topology and Quality

Plasmid DNA topology is a Critical Quality Attribute (CQA). The supercoiled isoform is preferred for its higher transfection efficiency and potency in inducing gene expression compared to open circular or linear forms [36]. Accurate quantification of the percentage of supercoiled plasmid is essential. Analytical methods for topology assessment include:

- Capillary Electrophoresis with Laser-Induced Fluorescence (CE-LIF)

- Agarose Gel Electrophoresis

- Anion Exchange Chromatography [36]

The United States Pharmacopeia (USP) is developing plasmid DNA reference materials to aid in the qualification and validation of in-house topology methods, ensuring consistency and reliability [36].

Critical Raw Materials and the Research Toolkit

The quality and consistency of raw materials are the bedrock of a reproducible rAAV manufacturing process. A controlled and well-understood supply chain for these materials is non-negotiable for clinical and commercial production.

The Researcher's Toolkit: Essential Materials for rAAV Production

Table 2: Critical Raw Materials for AAV Production: Sourcing and Function

| Material Category | Specific Examples | Critical Function in Production | Key Quality Considerations |

|---|---|---|---|

| Host Cell Lines | - HEK293 (adherent/suspension) [33] [27]- Sf9 Insect Cells [33] | - Platform for virus production. HEK293 provide necessary adenovirus E1 function [33]. | - Genetic stability, scalability, growth characteristics, post-translational modification patterns, and compliance with regulatory standards [35]. |

| Transfection Reagents | - Linear PEI, PEI MAX, PEI PRO [27] | - Form polyplexes with plasmid DNA to facilitate cellular uptake via endocytosis [27]. | - Transfection efficiency, cost at scale, variability between batches, and compatibility with serum-free media [27]. |

| Cell Culture Media | - BalanCD HEK293, FreeStyle 293, Viral Production Medium [27] | - Supports cell growth and viability. Chemically defined media reduce variability and enhance safety [35]. | - Formulation (e.g., serum-free, chemically defined), optimal for both growth and transfection, and low batch-to-batch variability [33] [27]. |