Accelerated Timelines: Strategies for Rapid and High-Quality Stable Cell Pool Selection

This article provides a comprehensive guide for researchers and drug development professionals seeking to compress cell line development timelines.

Accelerated Timelines: Strategies for Rapid and High-Quality Stable Cell Pool Selection

Abstract

This article provides a comprehensive guide for researchers and drug development professionals seeking to compress cell line development timelines. It explores the inherent bottlenecks of traditional stable cell pool generation and presents cutting-edge high-throughput, automated platforms that can reduce selection timelines from several months to mere weeks. Covering foundational principles, practical methodologies, common troubleshooting scenarios, and rigorous validation techniques, the content synthesizes recent case studies and technological innovations. The strategies discussed are critical for meeting the demands of developing complex biologics, such as bispecific antibodies, and accelerating the pace from discovery to clinical manufacturing.

Understanding Stable Cell Pool Bottlenecks and Economic Drivers

The Critical Role of CHO Cells in Biologics Production and Inherent Workflow Delays

Chinese Hamster Ovary (CHO) cells are the primary host system for biopharmaceutical production, used to manufacture a wide range of therapeutics, including monoclonal antibodies, recombinant proteins, and viral vectors [1] [2] [3]. Their ability to perform human-like post-translational modifications, grow in serum-free suspension cultures, and maintain relative safety from human pathogenic viruses makes them indispensable in the industry [3].

However, the development of high-producing, stable clonal cell lines is a major bottleneck. Traditional processes are labor-intensive, time-consuming, and plagued by inherent biological challenges that can lead to significant workflow delays, impacting the entire drug development timeline [4] [1]. This technical support center addresses these delays with targeted troubleshooting and optimized protocols.

Frequently Asked Questions (FAQs)

Q1: What are the most common causes of delay in cell line development? The most significant delays stem from clonal heterogeneity, the labor-intensive process of screening and characterizing many single-cell clones, and instability in both growth and protein expression over time [1] [5].

Q2: How can I reduce variability when assessing the effect of a genetic knockout? Relying on a small number of single-cell clones can be misleading due to high clonal heterogeneity. Using stable, genetically engineered knockout pools is a superior approach, as they reduce variability caused by clonal heterogeneity and better reflect the host cell population's phenotype [1].

Q3: Are there alternatives to lengthy stable clone generation for early-stage material? Yes, advanced technologies now enable the use of stable cell pools for generating early-stage materials. Transposase-mediated stable pools and site-specific integration systems can produce material with comparable performance and product quality to clonal cell lines, significantly accelerating timelines for preclinical and toxicology studies [4] [5].

Q4: What are the key technical factors that can disrupt cell culture and cause delays? Common technical issues include incubation problems (temperature variations, evaporation), media defects, and suboptimal technique (insufficient mixing, static electricity affecting cell attachment, or insufficient cell inoculum) [6].

Troubleshooting Guides

Problem: Slow Growth and Low Viability

| Possible Cause | Observation | Solution |

|---|---|---|

| Suboptimal Culture Conditions | Fluctuations in growth rate, low viability. | Calibrate incubator; avoid frequent opening; ensure humidification to minimize evaporation [6]. |

| Apoptosis | Declining viability in production bioreactors. | Engineer host CHO cells to knock out key apoptotic genes (e.g., Apaf1, Bak/Bax) to delay cell death and improve production titers [5] [3]. |

| Media Defects | Poor growth across multiple cultures. | Test with a new batch or different source of media; ensure high-quality supplements [6] [7]. |

Problem: Low Recombinant Protein Titer

| Possible Cause | Observation | Solution |

|---|---|---|

| Inefficient Transgene Integration | Low expression across many stable clones. | Use site-specific integration systems (e.g., targeted integration) instead of random integration for more predictable, high-level expression [5]. |

| Weak Translation Initiation | Adequate mRNA but low protein yield. | Optimize the vector by incorporating a strong Kozak sequence (e.g., GCCGCCRCC) upstream of the start codon to enhance translation efficiency [3]. |

| Inefficient Protein Secretion | Cellular stress, improper protein folding. | Use systems biology and omics approaches to identify and engineer bottlenecks in the protein secretion pathway within CHO cells [5]. |

Problem: Inconsistent Product Quality

| Possible Cause | Observation | Solution |

|---|---|---|

| Clonal Heterogeneity | High batch-to-batch variation in product quality attributes (e.g., glycosylation). | Screen a larger number of clones or use engineered stable pools to find a consistent producer. Employ AI models to predict long-term clone stability based on epigenetic properties [1] [5]. |

| Unidentified Host Cell Proteins | Impurities in the final product. | Use CRISPR to knockout specific genes in CHO hosts (e.g., FN1) that can reduce problematic host cell protein levels [1]. |

Quantitative Data for Informed Decision-Making

Timeline Compression with Alternative Workflows

| Workflow Type | Traditional Workflow Duration | Accelerated Workflow Duration | Key Technology Enabler |

|---|---|---|---|

| CRISPR Knockout Screening | 9 weeks [1] | 5 weeks [1] | Stable KO pools (singleplex/multiplex) |

| Stable Cell Line Generation | Several months [4] | Weeks [4] [5] | Transposase-mediated integration; Site-specific integration |

Impact of Vector and Host Engineering on Protein Yield

| Engineering Strategy | Target | Resulting Titer Increase |

|---|---|---|

| Vector Optimization [3] | Addition of Kozak + Leader sequence | eGFP: 2.2-fold; SEAP: ~1.5-fold (stable) |

| Host Cell Engineering [3] | Apaf1 Knockout | Increased recombinant protein production |

| Host Cell Engineering [1] | FN1 (Fibronectin 1) Knockout | Up to 2-fold increase in final titer |

Detailed Experimental Protocols

Protocol 1: High-Throughput CRISPR Knockout Using Stable Pools

This protocol compresses the knockout screening timeline from 9 to 5 weeks by avoiding single-cell cloning [1].

Materials:

- CHO DG44 cells (or other CHO host line)

- Synthetic sgRNAs (e.g., TrueGuide Synthetic gRNAs)

- Cas9 Protein (e.g., TrueCut Cas9 Protein v2)

- NEON Transfection System or similar

- Chemically defined, serum-free medium

Method:

- sgRNA Design: Design 3 sgRNAs per target gene using software (e.g., Geneious Prime, Benchling) targeting an early exon present in all transcript variants. Select for high on-target efficiency and low off-target scores.

- RNP Transfection: Pre-assemble ribonucleoproteins (RNPs) from sgRNA and Cas9 protein at a 1:1 ratio. Transfect 2x10^5 CHO cells using an electroporation system (e.g., 1700 V, 20 ms pulse width, 1 pulse).

- Pool Expansion and Validation: 48 hours post-transfection, expand the transfected cell population without single-cell cloning. Extract genomic DNA and validate editing efficiency via Sanger sequencing and ICE analysis.

- Phenotypic Screening: Maintain the pool for over 6 weeks to confirm genetic and phenotypic stability. Use fed-batch shake flask cultures to screen for desired phenotypic effects (e.g., improved late-stage viability, increased titer).

Protocol 2: Enhancing Expression via Vector Optimization

This protocol details how to boost recombinant protein expression by incorporating regulatory elements into the expression vector [3].

Materials:

- Parental expression vector (e.g., pCMV with your gene of interest)

- Molecular biology cloning reagents

- CHO-S cells

Method:

- Vector Construction:

- Construct 1 (Kozak): Clone a strong Kozak sequence (GCCGCCRCC) directly upstream of the start codon (ATG) of your target gene.

- Construct 2 (Kozak + Leader): Clone the same Kozak sequence followed by an appropriate leader peptide sequence upstream of the target gene.

- Transient Transfection: Transfect CHO-S cells with the parental vector, Construct 1, and Construct 2.

- Analysis: 48 hours post-transfection, analyze expression. For fluorescent proteins (e.g., eGFP), use flow cytometry to measure Mean Fluorescence Intensity (MFI). For secreted proteins (e.g., SEAP), assay the culture supernatant using an appropriate kit.

- Stable Pool Generation: Create stable pools under antibiotic selection and repeat expression analysis to confirm the sustained benefit of the regulatory elements.

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function | Example/Note |

|---|---|---|

| TrueCut Cas9 Protein v2 | CRISPR-mediated gene knockout in CHO cells [1]. | Used with synthetic sgRNAs to form Ribonucleoproteins (RNPs) for high-efficiency editing. |

| Transposase Enzyme | Enables stable, non-random integration of expression constructs [4]. | Faster generation of stable pools with high yields. |

| Kozak Sequence | Enhances translation initiation efficiency of mRNA [3]. | Sequence: GCCGCCRCC. |

| Leader Sequence | A signal peptide that aids in protein folding and secretion [3]. | Cloned upstream of the gene of interest. |

| Site-Specific Integration System | Targets transgene to a specific, well-characterized genomic locus [5]. | Reduces positional effect variability, accelerating cell line development. |

| FN1 sgRNA | Targets the Fibronectin 1 gene to prolong culture duration and improve viability [1]. | A validated target for host cell engineering. |

| Apaf1 sgRNA | Targets a key gene in the mitochondrial apoptosis pathway to reduce cell death [3]. | A validated target for inhibiting apoptosis. |

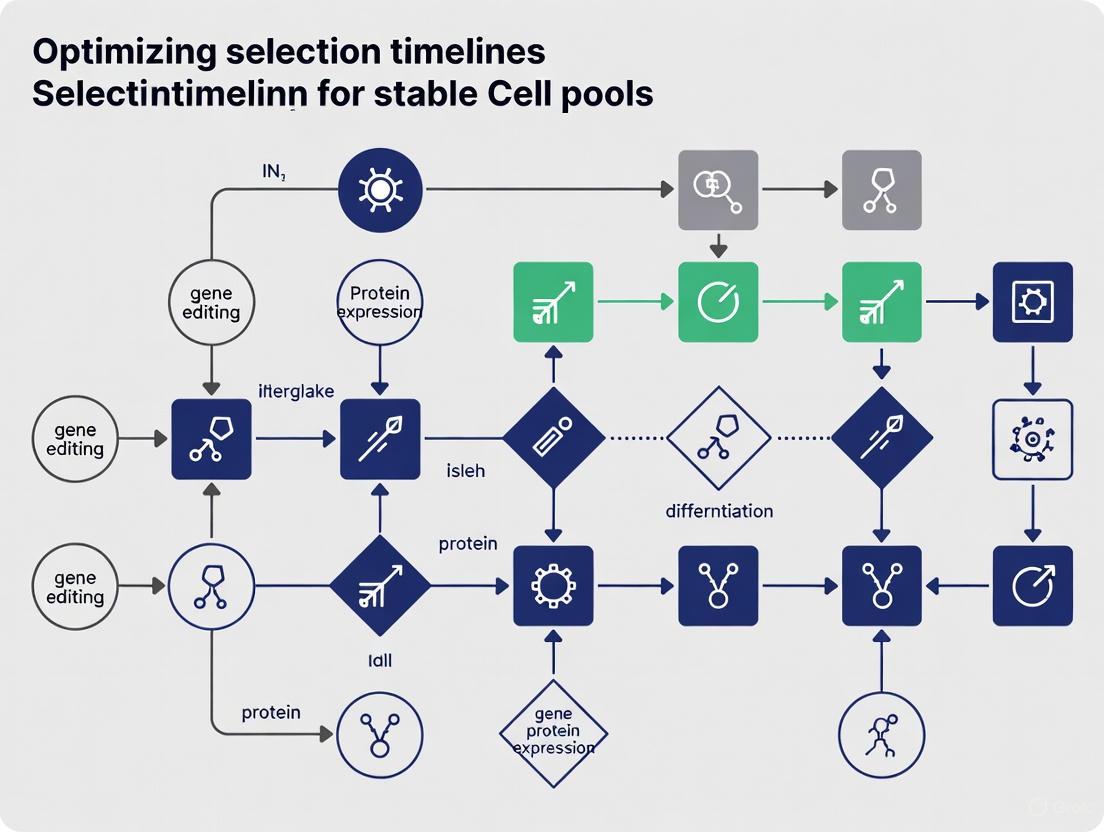

Workflow and Pathway Diagrams

CHO Cell Line Development Workflows

Strategies for CHO Cell Engineering

The development of stable cell pools is a critical foundation for biopharmaceutical research and development, enabling the production of recombinant proteins, monoclonal antibodies, and viral vectors. For years, the standard timeline for traditional stable cell line development has ranged from 6 to 12 months, with even the initial generation of stable pools often requiring approximately 3 months. This extended timeline creates significant bottlenecks in drug discovery and development pipelines, particularly as therapeutic modalities grow more complex.

This technical support center provides troubleshooting guidance and best practices for compressing these timelines, with a specific focus on achieving stable pool generation in as little as 7-10 weeks. The following sections are framed within a broader thesis on optimizing selection timelines for stable cell pool research, offering researchers actionable protocols, data-driven comparisons, and solutions to common experimental hurdles.

Quantitative Timeline Comparison: Traditional vs. Accelerated Processes

The transition to accelerated workflows represents a paradigm shift in cell line development. The table below quantifies the key differences between traditional and modern high-throughput approaches.

Table 1: Timeline Comparison of Traditional vs. Accelerated Stable Cell Pool Generation

| Process Phase | Traditional Timeline | Accelerated/High-Throughput Timeline | Key Acceleration Technologies |

|---|---|---|---|

| Overall Stable Cell Line Development | 6-12 months [8] | Not specified | |

| DNA to Fed-Batch Production | >3 months (approx. 12-14 weeks) [9] | 7-10 weeks [9] | Automated HTP platform, Leap-In transposase |

| Stable Pool Recovery & Small-Scale Material | Requires full recovery cycle [9] | 7 days post-transfection [9] | Early material supply from recovering pools |

| Pool Recovery & Working Stocks | Sequential stable transfections [9] | 14 days post-transfection [9] | Integrated automation (e.g., Lynx, NyOne) |

| Genetic Knockout Screening (Clonal) | ~9 weeks [1] | 5 weeks [1] | Pooled CRISPR knockout workflow |

Troubleshooting Guides and FAQs

FAQ: Addressing Common Timeline Challenges

Q1: What are the primary bottlenecks in a traditional 3-month stable pool development process? Traditional platforms are inherently sequential and labor-intensive [9]. They often involve repeated vector reformatting, low-throughput screening methods, and a requirement for separate transient expression campaigns to supply early-stage material, all of which cumulatively extend timelines [9].

Q2: How can we reduce variability and save time when screening genetic knockouts? Instead of relying on labor-intensive single-cell clones, which are highly variable and require screening hundreds of clones to find correctly edited ones, implement a stable knockout pool workflow [1]. This approach uses pools of genetically edited cells, reduces variability caused by clonal heterogeneity, and can compress screening timelines from 9 weeks to 5 weeks while increasing throughput 2.5-fold [1].

Q3: Our yields for bispecific antibodies are low due to production drift. How can we address this without extending our timeline? Implement a dual-antibiotic selection strategy. By designing vectors where each heavy chain is flanked by a different antibiotic resistance marker (e.g., blasticidin and puromycin), you can maintain yield and fidelity. One case study showed this strategy achieved titers over 3 times higher (2.7 g/L) compared to a single-selection control, and it has been successfully integrated into a standard 7-week HTP workflow [9].

Q4: What are the critical considerations for ensuring the genetic stability of rapidly developed cell pools? Genetic stability is paramount. While traditional methods like PCR and karyotyping are slow, Next-Generation Sequencing (NGS) is now the most accurate and comprehensive method. It provides a base-by-base view of the entire genome, allowing for early detection of genetic drift or mutations that could impact product quality and safety, thus ensuring regulatory compliance without sacrificing speed [10].

Troubleshooting Common Experimental Issues

Table 2: Troubleshooting Guide for Stable Pool Development

| Problem | Potential Cause | Solution | Preventive Measures |

|---|---|---|---|

| Low Titer Post-Transfection | Inefficient vector design or integration. | Screen multiple backbone vectors, promoters, and signal peptides in parallel [9]. | Use site-specific integration systems (e.g., Leap-In transposase) instead of random integration [9]. |

| Poor Viability in Fed-Batch | Suboptimal host cell line. | Engineer or use host cells with enhanced cellular machinery (e.g., CHOplus with increased ER capacity) [9]. | Employ a pooled CRISPR screen to identify gene knockouts (e.g., FN1) that improve late-stage viability [1]. |

| High Clonal Heterogeneity | Reliance on a limited number of single-cell clones. | Utilize stable knockout or expression pools to average out clonal variation [1]. | Implement high-throughput automation to screen a larger number of transfections in parallel (>1000) [9]. |

| Inconsistent Product Quality | Genetic instability of the cell pool over time. | Perform genetic stability testing using NGS to monitor the pool over serial passages [10]. | Characterize pools for critical quality attributes (CQAs) early in the development process. |

Detailed Experimental Protocols for Timeline Compression

Protocol 1: Automated High-Throughput Stable Pool Generation (7-10 Week Timeline)

This protocol outlines the end-to-end automated process for generating gram-scale material in 7-10 weeks [9].

Week 1: Vector Construction and Host Cell Preparation

- Vector Design: For bispecifics, use a dual-vector format with dual-antibiotic selection markers (e.g., blasticidin and puromycin). Perform killing curve assessments on the host cell line to determine optimal antibiotic concentrations [9].

- Host Cell Line: Use an engineered host line such as CHOZN or CHOplus. CHOplus has been shown to boost titers by 3.5-fold and can recover one week faster than standard CHOZN cells [9].

Week 1-2: High-Throughput Transfection and Selection

- Transfection: Perform >1,000 stable pool transfections in parallel using Leap-In transposase technology for multiple site-specific integrations [9].

- Automation: Integrate automated workstations (e.g., Lynx) for liquid handling and cell culture maintenance. Use imaging systems (e.g., NyOne) to monitor cell growth and confluence [9].

Day 7 Post-Transfection: Early Material Harvest

- Primary Screening: Harvest small-scale material (~150 μg) directly from the recovering pools. This eliminates the need for a separate transient expression campaign and allows for early-stage screening [9].

Day 14 Post-Transfection: Stable Pool Expansion

- Cell Banking: Freeze working cell banks of the recovered stable pools.

- Material Supply: Begin routine passages to supply 1-2 mg of material every 3-4 days for downstream assays [9].

Week 6-10: Fed-Batch Production and Analysis

- Scale-Up: Advance lead candidates to large-scale fed-batch production in bioreactor systems (e.g., Ambr15) [9].

- Analysis: Monitor titer, viability, and critical quality attributes (e.g., glycan profile) to select the final candidate [9].

Protocol 2: Pooled CRISPR Knockout Screening (5-Week Timeline)

This protocol describes a robust workflow for using stable knockout pools to evaluate gene targets, compressing the timeline from 9 to 5 weeks [1].

Week 1: sgRNA Design and RNP Complex Assembly

- sgRNA Design: Design three sgRNAs per target gene using software (e.g., Geneious Prime, Benchling) targeting an early exon present in all transcript variants. Select for high on-target efficiency and low off-target scores [1].

- RNP Assembly: Pre-assemble ribonucleoprotein (RNP) complexes using synthetic sgRNAs and Cas9 protein at a 1:1 ratio (e.g., 7.5 pmol each) [1].

Week 1: Cell Transfection and Culture

- Transfection: Transfect CHO cells (e.g., 2E5 cells) using an electroporation system (e.g., NEON Transfection System). Parameters: 1700 V, 20 ms pulse width, 1 pulse [1].

- Culture: Plate transfected cells in 24-well plates and expand as needed [1].

Week 2: Genotype Confirmation and Pool Expansion

- Genotyping: Extract genomic DNA 48 hours post-transfection. Perform PCR and Sanger sequencing of the target region. Analyze editing efficiency using software like ICE (Inference of CRISPR Edits) [1].

- Expansion: Expand the transfected cell population without single-cell cloning to create a heterogeneous but edited pool. This pool remains genetically stable for over 6 weeks, even in multiplexed formats targeting up to 7 genes [1].

Week 3-5: Phenotypic Screening in Fed-Batch Process

- Fed-Batch Assay: Inoculate shake flasks for a fed-batch bioprocess. Monitor viable cell concentration (VCC) and viability over time [1].

- Phenotypic Validation: Assess the phenotypic effect of the knockout (e.g., prolonged culture duration and improved late-stage viability for FN1 KO) and measure final product titer [1].

The Scientist's Toolkit: Essential Research Reagents and Solutions

The following table details key materials and technologies essential for implementing the accelerated workflows described in this guide.

Table 3: Research Reagent Solutions for Accelerated Stable Pool Development

| Reagent/Technology | Function | Application in Timeline Compression |

|---|---|---|

| Leap-In Transposase | Enables multiple site-specific genomic integrations of the gene of interest [9]. | Produces highly stable pools faster than random integration methods; core to the 7-week timeline [9]. |

| CHOplus Engineered Host | A CHOZN host cell line genetically engineered for enhanced endoplasmic reticulum (ER) capacity [9]. | Boosts titers by 3.5-fold and can reduce pool recovery time by one week [9]. |

| Dual-Antibiotic Selection | Uses two antibiotics (e.g., Blasticidin & Puromycin) to select for cells expressing all chains of a multispecific antibody [9]. | Minimizes production drift, improves bispecific yield and fidelity within the standard workflow [9]. |

| CRISPR/Cas9 RNP Complex | A pre-assembled complex of Cas9 protein and synthetic sgRNA for precise gene editing [1]. | Enables rapid generation of stable knockout pools without single-cell cloning, compressing target screening to 5 weeks [1]. |

| NGS (Next-Generation Sequencing) | A comprehensive method for genetic stability testing by sequencing the entire genome of a cell line [10]. | Provides rapid, base-by-base analysis to confirm genetic integrity of rapidly developed pools, ensuring quality and safety [10]. |

| High-Throughput Automation | Integrated robotic systems (e.g., Lynx, NyOne, Octet) for liquid handling, imaging, and analysis [9]. | Allows parallel processing of >1000 transfections, enabling massive throughput and reducing manual labor [9]. |

Facing patent cliffs and rising R&D costs, the biopharmaceutical industry is under immense pressure to accelerate development, particularly for complex modalities like bispecific antibodies and cell therapies. This technical support center provides targeted guidance to help researchers overcome critical bottlenecks in generating stable, high-producing cell pools—a key step in compressing these vital timelines.

Frequently Asked Questions & Troubleshooting

1. Our stable pools for bispecific antibodies have low yield and poor product fidelity. What strategies can improve this?

- Problem: Traditional selection methods for multi-chain molecules often lead to "production drift," where non-productive clones dominate, reducing yield and purity.

- Solution: Implement a dual-antibiotic selection strategy.

- Methodology: Design your expression vectors so that each heavy chain (e.g., HC1 and HC2) is flanked by a different antibiotic resistance marker, such as blasticidin (BSD) and puromycin (Puro). This ensures selective pressure for cells that have successfully integrated all necessary genetic components.

- Protocol:

- Conduct killing curve assays in your host cell line (e.g., CHOZN) to determine the optimal concentrations for both antibiotics.

- Co-transfect cells with your vectors and select using both antibiotics simultaneously.

- Culture and monitor the pools under these dual-selection conditions.

- Expected Outcome: This approach can significantly improve yield and fidelity. Case studies have shown a greater than threefold increase in titer (e.g., from 0.8 g/L to 2.7 g/L) compared to single-selection methods [9].

2. Our cell line development is slow and low-throughput, creating a discovery bottleneck. How can we increase speed?

- Problem: Conventional stable cell line development is sequential and labor-intensive, often taking over three months.

- Solution: Adopt an automated high-throughput (HTP) platform utilizing transposase-based technology.

- Methodology: Use Leap-In transposase technology for site-specific integration, combined with integrated automation for transfection, selection, and titer analysis.

- Protocol:

- Perform parallel transfections of thousands of stable pools in an automated workstation (e.g., Lynx).

- Use imaging systems (e.g., NyOne) and titer analysis (e.g., Octet) for rapid clone screening.

- For critical leads, use an opto-electronic system (e.g., Berkeley Lights Beacon) for clonal selection.

- Expected Outcome: This end-to-end automated system can reduce the timeline from DNA to large-scale fed-batch production to 7-10 weeks, cutting about a month from the standard process and enabling a single researcher to manage over 1,000 transfections [9].

3. We struggle with clonal variation and instability. Are there technologies to ensure consistent, high-yielding cell lines?

- Problem: Selection bias and unpredictable gene expression lead to clones that are unstable or have low productivity.

- Solution: Utilize platform technologies designed for site-specific integration and stability, such as the GPEx Lightning platform.

- Methodology: This platform uses a pre-engineered host cell line with specific "dock" sites and a recombinase enzyme to insert genes of interest site-specifically, without antibiotic selection.

- Protocol:

- Transfect cells with your gene of interest and the recombinase.

- The recombinase "flips" the gene into the pre-defined dock sites in the genome.

- Generate stable cell pools for rapid material production, or proceed to clonal selection.

- Expected Outcome: Generates highly stable cell pools and clones with consistent titers over many generations. Stable pools can produce titers of up to 12 g/L, and the process can deliver a research cell bank in as few as 40 days [11].

4. Our complex biologics have low titers even after optimization. Can host cell engineering help?

- Problem: Standard host cell lines may lack the cellular machinery to produce complex proteins at high yields.

- Solution: Employ engineered host cell lines with enhanced functionality.

- Methodology: Use hosts like CHOplus, which are engineered for increased endoplasmic reticulum (ER) capacity to handle the protein-folding load of complex molecules.

- Protocol:

- Substitute your standard host cell line (e.g., CHOZN) with the engineered alternative (CHOplus) in your standard CLD workflow.

- Proceed with stable pool generation and selection as usual.

- Expected Outcome: Engineered hosts can significantly boost productivity. In a bispecific program, using CHOplus resulted in a 3.5-fold increase in titer (from 0.33 g/L to 1.18 g/L) and faster pool recovery compared to the standard host [9].

Quantitative Data for Platform Comparison

The table below summarizes performance data from cited platforms to aid in selection and planning.

| Platform / Technology | Key Feature | Reported Output | Reported Timeline | Key Application |

|---|---|---|---|---|

| BMS HTP Platform [9] | Automated transposase-based integration | Titer: Up to 6 g/L (after vector optimization) | 7-10 weeks (DNA to production) | High-throughput mAb & bispecific screening |

| GPEx Lightning Platform [11] | Recombinase-mediated site-specific integration | Titer: ≤12 g/L (stable pools) | ~40 days (to stable pool) | Rapid production for complex molecules (e.g., 4-chain bispecifics) |

| Dual-Antibiotic Selection [9] | Selection for bispecific fidelity | Titer: 2.7 g/L (vs. 0.8 g/L for GS-only) | N/A (Integrated into workflow) | Improving yield & fidelity of bispecific antibodies |

| CHOplus Engineered Host [9] | Enhanced ER capacity | Titer: 1.18 g/L (vs. 0.33 g/L in CHOZN) | 1 week faster pool recovery | Boosting productivity for difficult-to-express molecules |

Essential Research Reagent Solutions

The following table lists key materials and technologies referenced in the experimental solutions.

| Reagent / Technology | Function | Example Use Case |

|---|---|---|

| Leap-In Transposase | Enables multiple site-specific genomic integrations for highly stable, high-producing pools. | Core technology in the BMS HTP platform for rapid stable pool generation [9]. |

| Dual-Antibiotic Vectors | Vectors with different resistance markers (e.g., BSD, Puro) for each chain to enforce co-expression. | Selecting for high-fidelity bispecific antibody production [9]. |

| CHOplus Engineered Host | A CHO host cell line engineered with enhanced ER capacity to improve protein folding and secretion. | Increasing titers for complex biologics where cellular capacity is a bottleneck [9]. |

| GPEx Lightning System | A platform using a pre-engineered cell line and recombinase for fast, stable gene insertion. | Accelerated development of stable cell pools for toxicology studies or early clinical material [11]. |

| Automated Workstations | Integrated systems (e.g., Lynx, NyOne, Octet) for hands-free cell culture, imaging, and analytics. | Enabling high-throughput parallel processing of thousands of stable transfections [9]. |

Experimental Workflow: Automated HTP Cell Line Development

The following diagram illustrates the integrated, automated workflow for high-throughput cell line development.

Stable Cell Pool Development Workflow

For projects requiring rapid material generation, the following workflow outlines the process for developing stable cell pools, from vector design to production.

In the pursuit of compressing biopharmaceutical development timelines, the use of stable cell pools has emerged as a powerful alternative to traditional single-cell cloning. This approach bypasses the labor-intensive and time-consuming process of clonal isolation and expansion, enabling a more direct assessment of a genetic modification's impact on the host cell population. The success of this strategy hinges on the rigorous monitoring of three critical, interdependent metrics during the pool selection timeline:

- Titer: The concentration of the therapeutic protein produced, which is the ultimate measure of cell line productivity.

- Viability: The percentage of living cells in a culture, which reflects overall cell health and culture longevity.

- Genetic Stability: The consistency of both the introduced genetic modification and the host cell genome over serial passages, which is essential for scalable and reproducible manufacturing processes.

Effectively defining and troubleshooting these metrics allows researchers to de-risk development, accelerate screening, and build a robust foundation for clinical manufacturing [1] [12].

Troubleshooting Guides

► Titer-Related Issues

Problem: Low or Unstable Protein Titer in Cell Pools

| Observation | Potential Root Cause | Recommended Action |

|---|---|---|

| Low titer from the start of culture | Low proportion of high-producing cells in the pool; inefficient transgene integration. | Increase the diversity of the initial mini-pool by screening a larger number of transfectants. Implement higher stringency selection pressure [12]. |

| Titer declines over prolonged culture | Genetic instability; loss of transgene or promoter silencing. | Perform stability studies over 70+ population doublings. Monitor genetic consistency via PCR or NGS at different time points [12]. |

| High titer but poor product quality | Suboptimal culture conditions driving undesirable post-translational modifications. | Optimize feed strategy and culture parameters (pH, temperature). Use machine learning (ML) to model complex interactions affecting product quality [13]. |

► Viability and Growth Issues

Problem: Poor Cell Growth or Rapid Viability Drop

| Observation | Potential Root Cause | Recommended Action |

|---|---|---|

| Poor growth after transfection | Cellular toxicity from the transfection or editing process. | Optimize transfection parameters (e.g., voltage, pulse width). Use high-quality, pre-assembled ribonucleoprotein (RNP) complexes for CRISPR editing [1]. |

| Viability crash during selection | Excessive selection agent pressure. | Titrate the concentration of the selection antibiotic (e.g., Puromycin) to determine the minimal effective dose that enriches edited cells without causing mass cell death [14]. |

| Gradual viability decline in extended fed-batch | Accumulation of metabolic by-products (e.g., lactate, ammonia) or depletion of essential nutrients. | Analyze metabolite profiles (glucose, lactate) to adjust feed strategies. Use spent media analysis to identify and replenish depleted nutrients [15]. |

| Cell clumping in suspension culture | Release of DNA from dead cells, increasing media viscosity. | Add harmless nucleases to the culture medium to degrade free DNA and reduce clumping [16]. |

► Genetic Stability Issues

Problem: Inconsistent or Lost Genetic Modifications in the Pool

| Observation | Potential Root Cause | Recommended Action |

|---|---|---|

| High editing efficiency but loss of KO phenotype over time | The cell pool is a mixed population, and unedited cells may outcompete edited ones. | Perform multiple transfections to increase the percentage of edited cells in the pool. Use high-fidelity Cas9 and validated sgRNAs to minimize off-target effects [1]. |

| Unintended genomic alterations | CRISPR off-target effects or genomic rearrangements from double-strand breaks. | Utilize computational tools to design sgRNAs with high on-target and low off-target scores. Perform whole-genome sequencing on the final selected pool to rule out major aberrations [1] [17]. |

| Inconsistent performance between scaled-up cultures | Genetic heterogeneity within the original pool leading to divergent population dynamics. | Ensure the master cell pool is created from a large, well-mixed population. Confirm that critical metrics (titer, viability) are maintained for at least 6 weeks (approx. 40-50 population doublings) to demonstrate stability [1]. |

Frequently Asked Questions (FAQs)

Q1: Why should I use a cell pool instead of a single clone for early-stage research? Cell pools provide a significant timeline advantage, compressing screening from approximately 9 weeks to just 5 weeks. They better represent the population-level phenotype of the host cell line and reduce the variability and potential bias introduced by clonal heterogeneity, which can be substantial in aneuploid cells like CHO. This makes pool-level data more reproducible for assessing the effect of a genetic knockout [1].

Q2: How long does it take to generate a stable, characterized cell pool? Using an optimized workflow, a research cell bank (RCB) of a stable pool can be generated in as little as 28 weeks. This timeline includes transfection, mini-pool generation and screening, productivity evaluation in scaled-down systems (e.g., Ambr 15 and 250), and final stability testing [12].

Q3: What is a key genetic stability benchmark for a CRISPR-edited knockout pool? A robust cell pool should demonstrate consistent genotypic (presence of the edit) and phenotypic (e.g., improved viability) stability for over 6 weeks in culture, which is comparable to the timeline required for a typical production bioreactor process [1].

Q4: How can I quickly check the editing efficiency in my cell pool without sequencing? The incorporation of an antibiotic resistance marker linked to the CRISPR edit allows for rapid enrichment of successfully edited cells. The efficiency can be inferred by the percentage of cells that survive selection pressure. However, genotypic confirmation via PCR and Sanger sequencing followed by ICE (Inference of CRISPR Edits) analysis is still required for quantitative validation [1] [14].

Q5: My cell pool has high viability but low titer. Where should I look first? First, confirm that the majority of cells in the pool contain the correct genetic modification. High viability with low titer can indicate a high proportion of non-producing cells that have outcompeted the producers. Analyze the pool's genetic consistency and reassess the selection strategy to ensure a high percentage of producing cells [1] [12].

Experimental Protocols & Workflows

► Protocol 1: Generating a Stable Knockout Pool Using CRISPR-Cas9

This protocol outlines the steps to create a genetically stable knockout (KO) cell pool, enabling high-throughput screening of gene targets without single-cell cloning [1] [14].

Key Reagents and Materials:

- Host CHO cells (or other cell line of interest)

- TrueCut Cas9 Protein v2

- Synthetic sgRNA (TrueGuide)

- NEON Transfection System & Kit

- Selection antibiotic (e.g., Puromycin)

Step-by-Step Methodology:

- sgRNA Design: Design 3-4 sgRNAs targeting an early exon of the target gene to cause frameshift mutations. Select guides based on high on-target efficiency scores and low off-target potential using software like Geneious or Benchling [1].

- RNP Complex Assembly: Pre-assemble the Cas9 protein and sgRNA at a 1:1 ratio (e.g., 7.5 pmol each) to form a ribonucleoprotein (RNP) complex. This complex is more precise and causes less cellular toxicity than plasmid-based methods.

- Cell Transfection: Transfect 2 x 10^5 cells using the NEON Transfection System with optimized parameters (e.g., 1700 V, 20 ms pulse width, 1 pulse).

- Pool Selection and Expansion: 48 hours post-transfection, begin applying the appropriate selection pressure. Expand the surviving cell population to create a heterogeneous but enriched knockout pool.

- Genotypic Validation: Extract genomic DNA from the pool. Amplify the target region by PCR and analyze the editing efficiency via Sanger sequencing and ICE analysis [1].

- Phenotypic Validation: Evaluate the pool in a fed-batch shake flask assay to confirm the expected phenotypic effect (e.g., prolonged viability, altered metabolic activity) [1].

► Protocol 2: Evaluating Pool Stability and Productivity

This protocol describes how to assess the critical metrics of titer, viability, and genetic stability over time to ensure pool robustness.

Key Reagents and Materials:

- Established cell pool

- Chemically defined culture medium

- Bench-top bioreactors (e.g., Ambr 15 or 250 systems)

- Metabolite Analyzer (e.g., BioProfile)

- PCR and sequencing reagents

Step-by-Step Methodology:

- Long-Term Stability Study: Passage the cell pool every 2-3 days for a minimum of 6 weeks (approximately 70 population doublings). Maintain parallel cultures to assess biological reproducibility [1] [12].

- Monitor Growth and Viability: Track viable cell density (VCD) and viability throughout the study using a cell counter (e.g., CASY). A stable, healthy pool will maintain consistent growth kinetics and high viability.

- Measure Productivity: Sample the culture supernatant at regular intervals (e.g., daily in fed-batch) and quantify protein titer using assays like HPLC or ELISA [12].

- Assess Genetic Stability: At designated time points (e.g., weeks 0, 3, and 6), sample the pool and re-run genotypic analysis (PCR/ICE) to confirm that the knockout is maintained in the population without reversion [1].

- Evaluate Product Quality: For pools producing therapeutic proteins, analyze critical quality attributes (CQAs) like charge variants at different time points to ensure process consistency [13].

► Workflow Diagram: Stable Cell Pool Generation & Screening

This diagram visualizes the integrated workflow from pool generation to final characterization, highlighting the compressed timeline.

The Scientist's Toolkit: Research Reagent Solutions

| Category | Item | Function in Pool Selection | Key Consideration |

|---|---|---|---|

| Cell Line Engineering | CRISPR-Cas9 RNP Complex | Enables precise gene knockout without plasmid integration. | Using pre-assembled RNP increases editing efficiency and reduces off-target effects [1]. |

| Synthetic sgRNA | Guides Cas9 to the specific genomic target site. | Design 3-4 per gene to mitigate variability in individual sgRNA efficiency [17]. | |

| Selection & Screening | Selection Antibiotics (e.g., Puromycin) | Enriches for cells that have successfully incorporated the edit. | Dose must be titrated to balance efficient selection with cell health [14]. |

| High-Throughput Bioreactors (e.g., Ambr systems) | Allows parallel, scaled-down fed-batch cultivation for clone and pool screening. | Provides highly predictive data for larger-scale performance [12]. | |

| Analytical Tools | Metabolite Analyzer (e.g., BioProfile) | Monitors concentrations of glucose, lactate, and other metabolites in real-time. | Essential for optimizing feed strategies and understanding cell health [15]. |

| ICE Analysis Software | Quantifies CRISPR editing efficiency from Sanger sequencing data. | A critical tool for genotypic validation without needing deep sequencing [1]. |

High-Throughput Platforms and Advanced Engineering for Rapid Selection

Leveraging Transposase Technologies (e.g., Leap-In) for Efficient Gene Integration

This technical support center provides troubleshooting and methodological guidance for researchers using transposase technologies, particularly the Leap-In Transposase platform, to optimize selection timelines for stable cell pool generation. The content is designed to help scientists and drug development professionals overcome common experimental hurdles and implement robust protocols that accelerate biologic drug development.

Troubleshooting Guide: Common Issues with Transposase-Mediated Stable Pool Generation

Table 1: Troubleshooting Common Problems in Stable Pool Generation

| Problem & Symptoms | Potential Root Cause | Recommended Solution | Expected Outcome |

|---|---|---|---|

| Low Transfection Efficiency & Poor Pool Recovery [9] • Low cell viability post-transfection • Few pools recovering after selection | • Low-quality DNA or mRNA • Suboptimal transfection reagent or conditions • Cytotoxicity from integration machinery | • Use high-quality, endotoxin-free plasmid DNA or mRNA. • Optimize transfection parameters (DNA:reagent ratio, cell density). • For Leap-In, use transposase mRNA to avoid genomic integration of transposase gene [18]. | Robust recovery of stable pools within 14 days post-transfection [9]. |

| Low Titer in Stable Pools [9] • Protein expression below expectations • Low productivity in fed-batch | • Suboptimal genetic construct • Inefficient integration into transcriptionally active regions • Low transgene copy number | • Screen multiple vector backbones, promoters, and signal peptides [9]. • Utilize platform hosts like CHOplus with enhanced ER capacity [9]. • Leverage Leap-In technology for integration into active chromatin [18]. | Titer improvements of >3-fold; case studies show gains from 0.33 g/L to >6 g/L [9]. |

| Poor Product Fidelity for Bispecifics [9] • Incorrect chain pairing • Low yield of functional molecule | • Genetic drift and dominance by non-productive cells during selection • Imbalanced expression of multiple chains | • Implement a dual-antibiotic selection strategy where each heavy chain (HC1, HC2) has a different resistance marker (e.g., blasticidin, puromycin) [9]. | Dramatically improved bispecific yield and fidelity; case study showed increase from <0.9 g/L to 2.7 g/L [9]. |

| Genetic Instability [18] • Drop in titer over extended culture (>60 generations) • Loss of transgene | • Random integration leading to gene silencing • Recombination of concatemeric inserts | • Use Leap-In transposase for single-copy, scarless integration, preventing repeat-induced silencing [18]. • Perform stability testing over 60 population doublings [18]. | Stable volumetric productivity and integrated transposon copy number over long-term culture [18]. |

Frequently Asked Questions (FAQs)

Q1: How does transposase technology fundamentally accelerate timelines compared to traditional methods?

Traditional cell line development (CLD) relying on random transgene integration is slow, low-throughput, and can take over three months from DNA to large-scale material [9]. Transposase-based systems, like Leap-In, leverage a "semi-targeted integration" (STI) mechanism that inserts single, intact copies of the transgene into transcriptionally active regions of the host genome [19]. This generates a stable, high-producing cell pool from the outset, eliminating the need for lengthy clonal screening campaigns during early development. This "pool-to-clone" strategy can compress the timeline from DNA to GMP manufacturing-ready material to under three months, saving several months compared to standard processes [9] [20].

Q2: What are the key advantages of using mRNA for transposase delivery over plasmid DNA?

Delivering the transposase as mRNA, rather than a plasmid, is a critical best practice. The mRNA is translated into a functional but transient transposase protein that performs the integration. The mRNA itself is then degraded by natural cellular pathways. This prevents the transposase gene from integrating into the host genome, ensuring that the transposon cannot be re-mobilized, which guarantees the long-term genetic stability of your stable pool or clonal line [18].

Q3: My project involves a complex molecule, like a bispecific antibody. What specific strategies can I use to ensure success?

For multi-chain proteins, achieving the correct stoichiometry is crucial. The Leap-In platform is particularly suited for this, as a single transposon can carry multiple open reading frames (ORFs) with the entire construct integrated intact, maintaining the designed expression ratios [18]. Furthermore, employing a dual-selection strategy is highly effective. By putting different selection markers (e.g., blasticidin and puromycin) on different chains of the bispecific antibody, you apply selective pressure for cells that have successfully integrated and express all required components, thereby minimizing drift toward non-productive cells and dramatically improving functional yield [9].

Q4: What are the typical yields I can expect from a stable pool, and when should I move to single-clone isolation?

Titers can vary based on the molecule, host cell, and process optimization. However, case studies with optimized systems report stable pool titers in the range of 1–3 g/L, with some programs achieving over 6 g/L [9]. The high quality of the stable pool means you can use it directly for generating early-stage material (e.g., for toxicology studies or early clinical trials). In parallel, you can initiate clonal isolation from the same high-producing pool to find an elite clone for higher commercial-scale production, which may achieve titers up to 5 g/L or more [20]. This dual-track approach de-risks and accelerates the entire development path.

Experimental Protocol: Generating a High-Titer Stable Pool Using Leap-In Transposase

This protocol outlines the generation of a recombinant stable cell pool using the Leap-In Transposase system in CHO host cells, designed for maximum efficiency and compressed timelines.

Key Reagent Solutions:

- Host Cells: CHOZN (BMS platform) or DG44 (ATUM platform) cells, adapted to serum-free media [9] [18].

- Transposon Vector: A Leap-In synthetic transposon containing your gene(s) of interest, flanked by Inverted Terminal Repeats (ITRs). For bispecifics, use a vector designed for multiple ORFs [18].

- Transposase: Leap-In Transposase mRNA (highly recommended over plasmid DNA).

- Selection Antibiotics: e.g., Puromycin, Blasticidin. Perform a killing curve assay in your host cell line to determine the optimal minimum concentration for selection [9].

Procedure:

Day -3 to 0: Host Cell Preparation

- Culture and expand your CHO host cells in an appropriate serum-free medium to ensure they are in log-phase growth and have >95% viability on the day of transfection.

Day 0: Co-transfection

- Seed cells at a pre-optimized density in a growth medium.

- Co-transfect the cells with the two key components:

- Synthetic Transposon DNA: Contains your gene(s) of interest.

- Leap-In Transposase mRNA: Facilitates the "cut-and-paste" integration.

- Use a transfection reagent and protocol optimized for your specific cell line.

Day 1: Post-Transfection Recovery

- Approximately 24 hours post-transfection, replace the transfection mixture with fresh growth medium.

Day 2: Initiation of Selection

- Begin selection by adding the pre-determined concentration of relevant antibiotics to the culture medium. This will eliminate untransfected cells that lack the resistance marker(s).

Day 7-14: Pool Recovery & Analysis

- Monitor cell viability and density closely. Viability should drop and then recover as the stable pool expands.

- By Day 7, small-scale material (~150 μg) can often be harvested from recovering pools for initial screening [9].

- By Day 14, the stable pool should be fully recovered. At this point:

- Freeze a working cell bank of the stable pool.

- Assess titer and product quality (e.g., via Octet, HPLC).

- The pool is now ready to be used to supply material (1-2 mg can be supplied every 3-4 days via routine passage) or to initiate fed-batch production for larger quantities [9].

Performance Data and Timeline Compression

Table 2: Quantitative Timeline and Titer Comparisons

| Metric | Traditional CLD (e.g., CHOZN) | HTP Transposase Platform (e.g., Leap-In) | Reference |

|---|---|---|---|

| Timeline (DNA to Fed-Batch) | >3 months | 7–10 weeks (saving ~1 month) | [9] |

| Stable Pool Recovery Time | N/A (not typically used) | ~14 days | [9] |

| Throughput (# Transfections) | Low-throughput, sequential | >1,000 stable pool transfections in parallel | [9] |

| Typical Stable Pool Titer (mAbs) | N/A | 1 - 3 g/L (case study range) | [9] [20] |

| Titer with Engineered Host (CHOplus) | Baseline | ~3.5x increase (e.g., from 0.33 g/L to 1.18 g/L) | [9] |

| GMP Manufacturing Readiness | 16–24 months | <6 months from transfection to Phase I trial start | [20] |

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagents for Transposase-Based Cell Line Development

| Reagent / Solution | Function & Description | Example Use Case |

|---|---|---|

| Leap-In Transposase mRNA | The enzyme that catalyzes the excision of the transposon from the donor vector and its integration into the host genome. Using mRNA ensures transient activity and long-term stability [18]. | Essential for all stable pool generation with the Leap-In system. |

| Synthetic Transposon (ITR-flanked Vector) | The DNA cargo to be integrated. It contains your gene(s) of interest and a selection marker, flanked by Inverted Terminal Repeats (ITRs) that are recognized by the transposase [18]. | Carries the therapeutic protein gene; can be designed with 2-4 ORFs for bispecific antibodies [18]. |

| CHOplus Engineered Host | A host cell line (e.g., based on CHOZN) engineered for enhanced endoplasmic reticulum (ER) capacity, reducing metabolic burden and increasing specific productivity [9]. | Boost titers for difficult-to-express molecules; shown to improve titer by 3.5x [9]. |

| Dual-Selection Antibiotics | Using two different antibiotics (e.g., Blasticidin and Puromycin), each linked to a different expression cassette. Ensures selective pressure for cells expressing all components of a complex molecule [9]. | Critical for maintaining yield and fidelity in bispecific antibody production. |

| VectorGPS Platform | A bioinformatics platform for the design and optimization of expression vectors, including codon optimization and expression balancing for multiple genes [18]. | Pre-experimental in-silico optimization of vector constructs to maximize productivity. |

Workflow Visualization

Stable Cell Pool Generation Workflow

Dual Selection Strategy for Bispecifics

Technical Support Center: Troubleshooting & FAQs

This technical support center addresses common challenges researchers face when integrating automated platforms like the Lynx automated workstation, Ambr bioreactor systems, and Octet analysis tools for stable cell pool development. The guidance is framed within the context of compressing selection timelines and enhancing productivity in biotherapeutics development.

Frequently Asked Questions (FAQs)

Q1: What are the key advantages of using an integrated Lynx, Ambr, and Octet platform for stable pool generation? An integrated high-throughput (HTP) platform significantly accelerates the timeline from DNA to stable cell pools and production-ready material. This system enables the parallel processing of over 1,000 stable pool transfections, provides early, small-scale material for primary screening within a week, and delivers high-titer, high-quality material in a fraction of the time required by conventional methods. It is designed to handle diverse molecule formats, including monoclonal and bispecific antibodies, by combining automation with optimized selection strategies [9].

Q2: Why might my stable pools for a bispecific antibody show low yield and poor product fidelity? This is often caused by production drift, where non-productive clones overtake the culture. A dual-antibiotic selection strategy can mitigate this. By constructing vectors where each heavy chain (HC1 and HC2) is flanked by a different antibiotic resistance marker (e.g., blasticidin and puromycin), you selectively pressure the cells to maintain both chains. This approach has been shown to increase titers more than threefold compared to using a single selection marker alone [9].

Q3: How can I increase the productivity of my CHO host cell line? Utilizing an engineered host cell line like CHOplus, which has enhanced endoplasmic reticulum (ER) capacity, can dramatically boost titers. In case studies, stable pools in CHOplus hosts recovered one week faster and achieved a 3.5-fold productivity increase compared to standard CHOZN cells. This host also maintains comparable product quality in terms of purity and glycan profiles [9].

Q4: My Octet titer measurements are inconsistent. What could be the issue? Ensure that the culture samples are properly homogenized before analysis, as air bubbles or cell debris can interfere with the bio-layer interferometry (BLI) signal. Consistent sample preparation is critical for reliable, quantitative titer data when using the Octet system for high-throughput screening [21].

Q5: What is the benefit of using a pooled CRISPR knockout (KO) workflow over a clonal one? A stable KO pool workflow directly screens genetically heterogeneous pools, reducing variability caused by clonal heterogeneity and better reflecting the host cell population's phenotype. This approach compresses screening timelines from 9 weeks to just 5 weeks and increases throughput by 2.5-fold by eliminating the need for single-cell clone isolation and expansion. The pools remain genetically stable for over 6 weeks, even when multiplexing targets [1].

Troubleshooting Guides

Table 1: Troubleshooting Stable Cell Pool Generation

| Problem Area | Potential Cause | Recommended Solution |

|---|---|---|

| Low Transfection Efficiency | Suboptimal transfection reagent or parameters | Use pre-assembled ribonucleoprotein (RNP) complexes with synthetic gRNA and Cas9 protein. Optimize electroporation parameters (e.g., 1700 V, 20 ms pulse width) [1]. |

| Poor Pool Recovery & Growth | Excessive antibiotic selection pressure | Perform a killing curve assessment for your host cell line to determine the optimal, non-lethal concentration of antibiotics (e.g., blasticidin, puromycin) for selection [9]. |

| Low Titer in Fed-Batch | Non-optimized culture process | Use the Ambr 15 or 250 systems for high-throughput media and feed screening to identify conditions that boost productivity, potentially doubling the final titer [12] [9]. |

| High Clonal Heterogeneity | Reliance on a limited number of clones | Implement a pooled screening approach using KO pools to assess genetic engineering effects, avoiding the bias and variability introduced by single-cell cloning [1]. |

Table 2: Troubleshooting Integrated System Operations

| Problem Area | Potential Cause | Recommended Solution |

|---|---|---|

| Data Integration Gaps | Systems (Lynx, Ambr, Octet) operating in siloes | Implement a centralized data management system to track samples and performance data across all platforms, enabling data-driven clone selection [9]. |

| Failed Scale-Up | Process conditions not representative | Use the Ambr 250 system to mimic larger bioreactor conditions and optimize parameters (pH, DO, feeding) before transferring to a 5 L benchtop bioreactor for confirmation [12]. |

| Inconsistent KO Phenotype | Clonal variation masking the true KO effect | Screen using stable KO pools to obtain a more reliable and reproducible phenotypic readout, as demonstrated with the FN1 KO which prolonged culture duration [1]. |

Experimental Protocols for Key Workflows

Protocol 1: High-Throughput Stable Cell Pool Generation & Titer Screening

This protocol outlines an automated, end-to-end process for rapidly generating and screening thousands of stable cell pools, compressing timelines to 7-10 weeks [9].

- Transfection: Use Leap-In transposase technology for site-specific integration in CHOZN or CHOplus host cells. Co-transfect >1,000 stable pools in a dual-vector format via an automated Lynx workstation.

- Selection & Recovery: Apply dual-antibiotic selection (e.g., GS + Blasticidin/Puromycin) 24-48 hours post-transfection. Monitor cell recovery and growth using integrated systems like the NyOne imaging system.

- Early-Stage Material Harvest: By day 7 post-transfection, harvest small-scale material (~150 µg) directly from the recovering pools for primary screening assays.

- High-Throughput Titer Analysis: Once pools are recovered (by day 14), use the Octet BLI platform (e.g., Octet RH96 or Red384) to rapidly quantify protein titers from culture supernatants [21] [9].

- Fed-Batch Evaluation: Advance high-producing pools to a micro-bioreactor system like Ambr 15 for small-scale fed-batch culture to evaluate growth, viability, and productivity under process-like conditions [21].

Protocol 2: Pooled CRISPR-KO Screening for Host Cell Line Engineering

This protocol describes a method for rapidly evaluating gene knockout effects using stable KO pools, reducing timelines from 9 to 5 weeks [1].

- sgRNA Design: Design three sgRNAs per target gene using software like Geneious Prime or Benchling. Target an early exon present in all transcript variants to induce frameshift mutations.

- RNP Transfection: Pre-assemble RNP complexes using 7.5 pmol of synthetic gRNA and Cas9 protein. Transfect into host cells (e.g., 2E5 CHO DG44 cells) using an electroporation system (e.g., NEON Transfection System) with parameters set to 1700 V, 20 ms, 1 pulse.

- Genotype Confirmation: 48 hours post-transfection, extract genomic DNA and perform PCR on the target region. Use Sanger sequencing and ICE analysis to confirm editing efficiency.

- Phenotypic Screening in Fed-Batch: Culture the heterogeneous KO pools in shake flasks or micro-bioreactors in fed-batch mode. Monitor culture duration, late-stage viability, and final titer. Compare to wild-type pools to identify beneficial KO effects, such as the two-fold titer increase observed with FN1 KO [1].

System Workflow Diagrams

The following diagram illustrates the integrated workflow and data flow between the Lynx, Ambr, and Octet systems within an automated cell line development platform.

Integrated Automated Workflow for Stable Pool Development

This logical workflow shows how automation and micro-scale cultivation are intertwined, with the Octet system serving as a key analytical node for decision-making.

Research Reagent Solutions

The table below lists essential materials and reagents used in the integrated automated workflows described.

Table 3: Key Research Reagents and Materials

| Item | Function in the Workflow |

|---|---|

| CHOZN / CHOplus Host Cells | The mammalian host cell line used for stable integration and recombinant protein production. CHOplus is engineered for enhanced ER capacity and higher productivity [9]. |

| Leap-In Transposase System | Enables site-specific integration of the gene of interest into the host cell genome, leading to highly stable pools and faster recovery compared to random integration [9]. |

| Synthetic gRNA & Cas9 Protein | Pre-complexed as Ribonucleoproteins (RNPs) for highly efficient CRISPR-Cas9 gene editing in host cell line engineering workflows [1]. |

| Dual-Antibiotic Markers (e.g., Blasticidin, Puromycin) | Used in bispecific antibody production to apply selective pressure for maintaining both heavy chains, thereby improving yield and product fidelity [9]. |

| Chemically Defined Media & Feeds | Optimized formulations used in the Ambr systems for fed-batch cultures to support high viable cell density and protein titer [12] [9]. |

This case study details the implementation of an automated high-throughput (HTP) stable CHO cell platform, which successfully compressed the cell line development timeline by approximately two months compared to traditional processes. The core achievement was the parallel processing of over 1,000 stable pool transfections to deliver material from DNA to large-scale fed-batch production in just 7–10 weeks [9].

The table below summarizes the key quantitative outcomes from the platform implementation.

Table 1: Summary of Key Experimental Outcomes

| Metric | Traditional Process | HTP Platform | Improvement |

|---|---|---|---|

| Total Timeline (DNA to Production) | ~3-4 months [9] | 7-10 weeks [9] | Shortened by ~2 months [9] |

| Stable Pool Throughput | Low-throughput, sequential | >1,000 pools in parallel [9] | Massive parallelization |

| Lead mAb Titer | Baseline (e.g., ~0.9 g/L for a challenging mAb) [9] | Up to 6 g/L after vector optimization [9] | ~7-fold increase |

| Material for Primary Screening | Required waiting for stable pools | Available by Day 7 post-transfection [9] | Enabled earlier decision-making |

| Bispecific mAb Titer | ~0.9 g/L (GS-only selection) [9] | 2.7 g/L (with dual-antibiotic selection) [9] | ~3-fold increase |

Detailed Experimental Protocols

Core Workflow for High-Throughput mAb Expression

The following protocol was used to screen 575 monoclonal antibodies (mAbs) and deliver large-scale material [9].

Transfection:

- Technology: Leap-In transposase technology was used for multiple site-specific genomic integrations [9].

- Scale: Co-transfection of >1,000 stable pools in CHOZN cells was performed in a dual-vector format, with duplicates [9].

- Automation: An integrated automated workstation (Lynx) was employed for high-throughput handling [9].

Selection & Recovery:

- Process: Cells underwent selection and recovery post-transfection.

- Monitoring: The process was monitored using a NyOne imaging system and Octet for titer analysis [9].

Early-Stage Material Supply:

Pool Recovery and Expansion:

- By Day 14, stable pools were fully recovered.

- Working cell banks were frozen, and the system could continuously supply 1 mg to 2 mg of material from routine passages every 3-4 days [9].

Clone Selection and Scale-Up:

- The top four lead mAbs were advanced to large-scale fed-batch production in bioreactors for further testing (e.g., immunogenicity, PK) [9].

Protocol for Improving Bispecific mAb Yield

For complex molecules like bispecific antibodies, a dual-antibiotic selection strategy was implemented to prevent production drift and ensure balanced chain expression [9].

Vector Design:

- Two heavy chains (HC1 and HC2) were cloned into separate vectors, each flanked by a different antibiotic resistance marker (e.g., blasticidin (BSD) and puromycin (Puro)) [9].

Killing Curve Assessment:

- The optimal antibiotic concentrations for selection were determined by performing killing curve assays in CHOZN host cells [9].

Transfection and Selection:

- Stable transfections were performed in triplicate under different selection conditions:

- GS only (control)

- GS + BSD/Puro (low concentration)

- GS + BSD/Puro (high concentration) [9]

- The highest-yielding pool was identified via titer analysis.

- Stable transfections were performed in triplicate under different selection conditions:

Workflow Visualization

The diagram below illustrates the integrated workflow of the automated HTP platform, highlighting the parallel processing path and key technological integrations.

The Scientist's Toolkit: Key Research Reagents & Equipment

The successful implementation of this HTP platform relied on a suite of specialized reagents, instruments, and technologies.

Table 2: Essential Research Reagents and Solutions

| Category | Item | Function / Application |

|---|---|---|

| Core Technology | Leap-In Transposase | Enables multiple site-specific genomic integrations for highly stable pools [9]. |

| Host Cell Line | CHOZN Cells | The baseline host cell line for stable transfection [9]. |

| CHOplus Engineered Host | An engineered CHOZN host with enhanced ER capacity, boosting titers by up to 3.5-fold [9]. | |

| Selection Agents | Blasticidin (BSD) & Puromycin | Dual-antibiotic selection for bispecifics to maintain yield and fidelity [9]. |

| Automation & Analysis | Lynx Automated Workstation | Automates liquid handling for medium-to-high-throughput workflows [9]. |

| NyOne Imaging System / Cell Metric | Provides imaging for cell growth and confirmation of single-cell cloning [9] [22]. | |

| Octet System | Performs high-throughput, label-free titer analysis via Biolayer Interferometry (BLI) [9] [23]. | |

| VIPS (Verified In-Situ Plate Seeding) | Images droplets to guarantee monoclonality (single cell per well) for regulatory assurance [22]. | |

| Ambr 15 Cell Culture System | Automated micro-bioreactor system for scalable fed-batch cultivation and process optimization [9] [23]. |

Frequently Asked Questions (FAQs) & Troubleshooting

Q1: Our stable pools for bispecific antibodies show good initial titer but a rapid drop in yield. What could be the cause? A1: This is a classic symptom of production drift, where non-productive cells outcompete productive ones. Implement a dual-antibiotic selection strategy where each heavy chain is linked to a different resistance marker (e.g., Blasticidin and Puromycin). This maintains selective pressure for cells expressing both chains, preserving yield and product fidelity [9].

Q2: How can I supply material for early-stage assays while stable pools are still developing? A2: The HTP platform demonstrates that you can harvest small-scale material (~150 µg) directly from recovering stable pools as early as 7 days post-transfection. This eliminates the need for a separate, resource-intensive transient expression campaign, accelerating early screening and decision-making [9].

Q3: Our cell line development is bottlenecked by the slow, manual process of single-cell cloning and monoclonality assurance. Are there solutions? A3: Yes, integrate automated cell imagers and dispensers. Instruments like the VIPS (Verified In-Situ Plate Seeding) image the droplet deposited into each well to confirm it contains a single cell, providing crucial documentation for regulatory compliance. The CellCelector system can also automate the screening of tens of thousands of clones with high probability of monoclonality (99.7%) [22] [24].

Q4: We are screening many clones, but the top producers in plates do not perform well in bioreactors. How can we improve clone selection? A4: Incorporate a scale-down model earlier in your workflow. Using a 96-well deep-well plate to run a small-scale fed-batch culture that mirrors your production process (Ambr 15 bioreactor conditions) helps identify and exclude clones whose performance does not translate to larger scales. This refines your selection and increases the chance of finding truly high-performing clones [24].

Q5: What are the main barriers to adopting an automated HTP platform like this? A5: The primary challenges include the high initial equipment costs, the complexity of integrating multiple automated systems, and the need for specialized training. Additionally, licensing agreements for technologies like Leap-In transposase may be required. For some very low-expressing constructs, additional optimization cycles might still be necessary despite the platform's throughput [9].

Frequently Asked Questions (FAQs)

Q1: What are CHOplus engineered host cells, and how do they enhance productivity? CHOplus refers to engineered Chinese Hamster Ovary (CHO) host cells designed with enhanced cellular machinery to boost recombinant protein production. A key improvement is the increased endoplasmic reticulum (ER) capacity, which alleviates a major bottleneck in protein processing and secretion [9]. In practice, this engineering has been shown to enable stable pools to recover one week faster and achieve a 3.5-fold productivity increase in large-scale fed-batch cultures, with titers rising from 330 mg/L in base CHO hosts to over 1.18 g/L in CHOplus hosts [9].

Q2: How do engineered hosts fit into a timeline for optimizing stable cell pools? Advanced host cell engineering is a foundational strategy for compressing selection timelines for stable cell pools. By starting with a host that has inherently higher productivity and faster growth, the entire cell line development process is accelerated. One automated high-throughput (HTP) platform demonstrated that using such engineered hosts enables moving from DNA to large-scale fed-batch production in just 7 to 10 weeks, cutting about a month off the conventional timeline [9].

Q3: What specific cellular pathways are targeted by host cell engineering to increase productivity? Engineering strategies often target pathways controlling cell proliferation, protein synthesis, and secretion. Key targets include:

- Transcription and Translation Factors: Overexpression of factors like eIF3i and eIF3c enhances cell growth and recombinant protein synthesis [25].

- Transcription Factors: Co-overexpression of MYC and XBP1s has been shown to increase both cell proliferation and recombinant protein production [25].

- Secretory Pathway Capacity: As seen with CHOplus, directly engineering the ER capacity helps the cell manage the load of producing complex therapeutic proteins [9].

Q4: Are there any drawbacks to using these advanced engineered host systems? While offering significant benefits, adoption can be constrained by upfront equipment costs for automated platforms, integration complexity, and training needs [9]. Licensing agreements for technologies like transposase systems may also be required [9]. For some very low-expressing or unstable constructs, additional optimization cycles might still be necessary even with an engineered host [9].

Troubleshooting Guides

Problem 1: Low Titer in Stable Pools

Potential Causes and Solutions:

- Cause: Inefficient Transgene Integration

- Solution: Move from random integration to targeted integration technologies like Leap-In transposase. This technology supports multiple site-specific integrations, producing highly stable pools with higher titers in shorter timelines [9].

- Cause: Limitations in Host Cell Capacity

- Solution: Utilize an engineered host like CHOplus. Case studies show that switching from a conventional CHO host to CHOplus #1 increased titers from 330 mg/L to 1.14-1.18 g/L for a bispecific molecule [9].

- Cause: Suboptimal Vector Design

- Solution: Perform high-throughput vector optimization. Screen different backbone vectors, promoters, and signal peptides. One study screened 60 combinations and achieved a titer of >6 g/L, a nearly sevenfold improvement over the baseline [9].

Problem 2: Slow Recovery and Outgrowth of Stable Pools

Potential Causes and Solutions:

- Cause: Poor Clonal Outgrowth Post-Single Cell Seeding

- Solution: Supplement cloning media with specialized additives like InstiGRO CHO PLUS. Testing showed the improved formulation of this supplement significantly enhanced both clonal outgrowth percentage and average colony size, speeding up the expansion of monoclonal lines [26].

- Cause: Inherent Host Cell Growth Characteristics

- Solution: Implement host cell engineering. CHOplus hosts have demonstrated a one-week faster recovery of stable pools compared to standard CHOZN hosts [9].

Problem 3: Poor Fidelity in Bispecific Antibody Production

Potential Cause and Solution:

- Cause: Production Drift and Non-Productive Cells

- Solution: Implement a dual-antibiotic selection strategy. Design vectors with each heavy chain (HC1 and HC2) flanked by different antibiotic resistance markers (e.g., blasticidin and puromycin). This ensures selective pressure for cells expressing all necessary chains. One case study using this method achieved a titer of 2.7 g/L, over three times higher than the control with single selection [9].

The following tables consolidate key performance metrics from published case studies.

Table 1: Performance Comparison of Engineered Hosts

| Host Cell Type | Time to Pool Recovery | Fed-Batch Titer (Example) | Key Feature | Source |

|---|---|---|---|---|

| CHOplus #1 | ~1 week faster | 1.14 - 1.18 g/L | Enhanced ER capacity | [9] |

| CHOplus #2 | ~1 week faster | 690 mg/L | Enhanced ER capacity | [9] |

| Base CHOZN | Standard timeline | 330 mg/L | Conventional host | [9] |

Table 2: Impact of Selection Strategies on Bispecific Antibody Titer

| Selection Strategy | Average Titer Achieved | Key Benefit | Source |

|---|---|---|---|

| Dual-Antibiotic (GS + BSD/Puro High) | 2.7 g/L | Ensures expression of all chains, improves fidelity | [9] |

| Single Selection (GS only) | < 0.9 g/L | Standard method, prone to production drift | [9] |

Experimental Protocols

Protocol 1: High-Throughput Stable Pool Generation Using Transposase Technology

This protocol outlines the generation of stable pools using Leap-In transposase technology for compressed timelines [9].

- Host Cell Preparation: Use an engineered host cell line (e.g., CHOplus) cultivated in serum-free medium.

- Vector Design: Clone the gene of interest into a transposase donor vector. For bispecifics, use a dual-vector system with separate antibiotic markers for each heavy chain.

- Transfection: Co-transfect host cells with the donor vector and a transposase vector. The HTP platform allows for >1,000 transfections in parallel.

- Selection & Recovery: Between 24-48 hours post-transfection, add appropriate antibiotics for selection. Monitor cell growth and viability using automated systems (e.g., Lynx workstation, NyOne imager).

- Small-Scale Material Generation: As early as 7 days post-transfection, harvest small amounts of material (~150 μg) from recovering pools for early screening.

- Pool Expansion: By day 14, stable pools are typically recovered. Freeze working cell banks and use the pools for material supply (1-2 mg every 3-4 days) or advance to clone screening.

Protocol 2: Dual-Antibiotic Selection for Bispecific Antibodies

This protocol details the strategy to minimize production drift in bispecific antibody production [9].

- Killing Curve Assay: First, perform killing curve assays in your CHO host for antibiotics like blasticidin (BSD) and puromycin (Puro) to determine the minimum concentration that kills all non-transfected cells within 7-14 days.

- Vector Construction: Create two expression vectors:

- Vector A: HC1 and Light Chain 1 + BSD resistance gene.

- Vector B: HC2 and Light Chain 2 + Puro resistance gene.

- Co-transfection: Transfect host cells with both Vector A and Vector B at a balanced ratio (e.g., 1:1).

- Dual Selection: Apply both BSD and Puro antibiotics at the predetermined concentrations 24-48 hours after transfection.

- Pool Evaluation: Maintain selection pressure for 14-21 days. Monitor titer and product quality (e.g., correct chain assembly) to confirm improved fidelity and yield.

Signaling Pathways and Workflows

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Reagents for Advanced Host Cell Engineering and CLD

| Item | Function | Example / Note |

|---|---|---|

| CHOplus Engineered Host | Host cell line with enhanced ER and secretory capacity for higher productivity and faster recovery. | Clone #1 showed 3.5x titer increase in case study [9]. |

| Transposase System | Enables efficient, site-specific gene integration for generating highly stable pools. | e.g., Leap-In transposase technology [9]. |

| InstiGRO CHO PLUS | Cell culture supplement formulated to enhance clonal outgrowth and average colony size after single-cell seeding. | Improved formulation increases cloning efficiency [26]. |

| Dual-Antibiotic Selection | Uses two antibiotics (e.g., Blasticidin, Puromycin) to ensure high-fidelity production of multi-chain proteins like bispecific antibodies. | Critical for preventing production drift [9]. |

| Automated Bioreactor Systems | High-throughput, small-scale bioreactors for clone screening and process optimization. | e.g., Ambr 15 and Ambr 250 systems [12]. |

| Automated Cell Imager & Sorter | Instrument for imaging clonal colonies and reliably selecting high-producing monoclonal cell lines. | e.g., CellCelector platform [12]. |

CRISPR-Cas9 Ribonucleoprotein (RNP) Delivery for Rapid and Precise Host Cell Line Engineering

Frequently Asked Questions (FAQs)

Q1: What are the main advantages of using RNP over plasmid DNA (pDNA) for CRISPR delivery? Direct delivery of pre-assembled Cas9 protein and guide RNA as a Ribonucleoprotein (RNP) complex offers several critical advantages for generating stable cell pools:

- Reduced Off-Target Effects & High Fidelity: The RNP complex is active immediately upon delivery but has a short intracellular lifetime, minimizing prolonged Cas9 activity that can lead to unwanted mutations at off-target sites. Sequencing studies have shown this approach results in editing with high fidelity and no detected off-target activity [27].