Advanced Cell Cryopreservation Protocols: Optimizing Freezing and Thawing for Enhanced Viability in Biomedical Research

This article provides a comprehensive guide to cell cryopreservation for researchers and drug development professionals.

Advanced Cell Cryopreservation Protocols: Optimizing Freezing and Thawing for Enhanced Viability in Biomedical Research

Abstract

This article provides a comprehensive guide to cell cryopreservation for researchers and drug development professionals. It covers the fundamental principles of cryobiology, detailed step-by-step protocols for freezing and thawing, advanced troubleshooting for common issues, and a comparative analysis of emerging technologies. The content synthesizes current industry practices and recent scientific findings to help optimize cell viability, maintain stemness, and ensure reproducibility in advanced therapies and research applications.

The Science of Cryopreservation: Core Principles and Critical Preparations for Cell Survival

This application note details the critical role of cryopreservation in biomedical research and drug development for preserving genetic integrity and establishing secure backup cell stocks. We provide a consolidated overview of the principles underpinning successful cryopreservation, followed by detailed, actionable protocols for the freezing and thawing of mammalian cells. The note includes standardized methodologies, optimized reagent solutions, and data presentation to ensure experimental reproducibility and maximize post-thaw cell viability and function.

Cryopreservation is a cornerstone technique for the long-term storage of living cells and tissues at ultra-low temperatures, typically below -150°C in liquid nitrogen, effectively halting all metabolic activity [1] [2]. Its importance extends far beyond simple storage; it is an essential strategy for maintaining genetic integrity, preventing phenotypic drift, and creating reliable backup stocks for research reproducibility and biopharmaceutical production [3] [1]. Without cryopreservation, maintaining cell lines in continuous culture leads to significant risks, including genetic instability due to selective pressures, increased chances of microbial contamination, and substantial investments in time and resources [2]. Implementing a robust cell banking system is therefore indispensable for safeguarding valuable cell lines, including primary cells and stem cells, ensuring they remain available with consistent characteristics for future experiments, cell-based assays, and therapeutic applications [3] [4].

Quantitative Data and Analysis

The following tables summarize key quantitative parameters for successful cryopreservation, derived from established best practices.

Table 1: Standard Cryopreservation Parameters for Mammalian Cells

| Parameter | Recommended Range | Rationale & Impact |

|---|---|---|

| Cell Viability Pre-Freeze | >75% [1] | Ensures a healthy population is preserved; lower viability compromises recovery. |

| Cell Concentration | 1x10^6 to 5x10^6 cells/mL [5] [1] | Prevents overcrowding and resource competition; avoids apoptosis from low density. |

| Cooling Rate | -1°C/minute [5] [1] [4] | Allows water to exit cells slowly, minimizing lethal intracellular ice crystallization. |

| Storage Temperature | < -150°C (Liquid Nitrogen) [2] | Halts all biochemical activity, enabling virtually indefinite storage. |

| DMSO Concentration | 10% (v/v) [1] [4] | Common standard; balances cryoprotection with cytotoxicity. |

Table 2: Cryoprotectant Agent (CPA) Comparison

| Cryoprotectant | Type | Common Usage | Key Considerations |

|---|---|---|---|

| Dimethyl Sulfoxide (DMSO) | Penetrating [4] | 10% in culture medium or serum [1] | Gold standard; can be cytotoxic and requires rapid post-thaw removal [1]. |

| Glycerol | Penetrating [4] | 10% in culture medium or serum [1] | Slower cell permeability; often used for red blood cells and certain sensitive cells. |

| Trehalose | Non-Penetrating [4] | 20-100mM in combination with other CPAs | Stabilizes membranes; often used in vitrification mixtures to reduce toxicity of PAs [4]. |

Experimental Protocols

Protocol: Cryopreservation of Mammalian Cells

This protocol is adapted from established best practices for freezing adherent and suspension mammalian cell lines [5] [1].

Principle: To preserve cells at a specific passage in a state of suspended animation by using a controlled slow freeze in the presence of cryoprotectants, ensuring high viability and functionality upon thawing.

Materials:

- Healthy, log-phase cells (70-80% confluent for adherent cells) [5]

- Appropriate cell culture medium

- Cryopreservation medium (e.g., 90% FBS + 10% DMSO, or serum-free alternatives) [1]

- Trypsin-EDTA (for adherent cells)

- Phosphate Buffered Saline (PBS)

- Centrifuge tubes

- Programmable freezer or isopropanol freezing chamber (e.g., CoolCell) [1]

- Cryogenic vials

- -80°C Freezer

- Liquid nitrogen storage tank

Methodology:

- Cell Harvesting: For adherent cells, wash with PBS, trypsinize, and neutralize with complete medium. For suspension cells, proceed directly [1].

- Cell Counting and Viability Assessment: Centrifuge the cell suspension (300 x g, 5 min). Resuspend the pellet and perform a cell count and viability assay (e.g., Trypan Blue exclusion). Ensure viability is >75% [5] [1].

- Centrifugation and Resuspension: Centrifuge the required volume of cell suspension again. Aspirate the supernatant completely.

- Freezing Medium Addition: Gently resuspend the cell pellet in pre-chilled freezing medium to achieve a final concentration of 1-5 x 10^6 cells/mL. Keep the tube on wet ice [5].

- Aliquoting: Quickly aliquot 1 mL of the cell suspension into labeled cryovials.

- Controlled-Rate Freezing: Immediately place the cryovials into a pre-cooled isopropanol freezing chamber and transfer it to a -80°C freezer for a minimum of 4 hours (ideally overnight). The chamber ensures a cooling rate of approximately -1°C/minute [5] [1].

- Long-Term Storage: The following day, promptly transfer the cryovials to the vapor phase of a liquid nitrogen storage tank for long-term preservation [5].

Protocol: Thawing and Recovery of Cryopreserved Cells

Principle: To rapidly reanimate frozen cells while minimizing the cytotoxic effects of cryoprotectants like DMSO and osmotic stress, thereby maximizing cell recovery.

Materials:

- Cryovial of frozen cells

- 37°C water bath

- Pre-warmed complete culture medium

- Centrifuge tubes

- Culture vessel

Methodology:

- Rapid Thaw: Retrieve the cryovial from liquid nitrogen storage. Without delay, immerse it in a 37°C water bath with gentle agitation until only a small ice crystal remains (approximately 60-90 seconds). Do not submerge the vial cap [5] [1].

- Decontamination: Wipe the exterior of the vial with 70% ethanol before transferring to a biosafety cabinet.

- Dilution and Cryoprotectant Removal: Gently transfer the thawed cell suspension to a centrifuge tube containing 10 mL of pre-warmed complete medium. This rapid dilution reduces DMSO toxicity [1].

- Centrifugation: Centrifuge the cell suspension at 300 x g for 5 minutes. Discard the supernatant.

- Resuspension and Plating: Gently resuspend the cell pellet in fresh, pre-warmed complete culture medium. Transfer the cells to an appropriate culture vessel and place in a 37°C, 5% CO₂ incubator [1].

- Post-Thaw Assessment: After 24 hours, perform a visual inspection for cell attachment (adherent cells) and a viability count to confirm successful recovery [5].

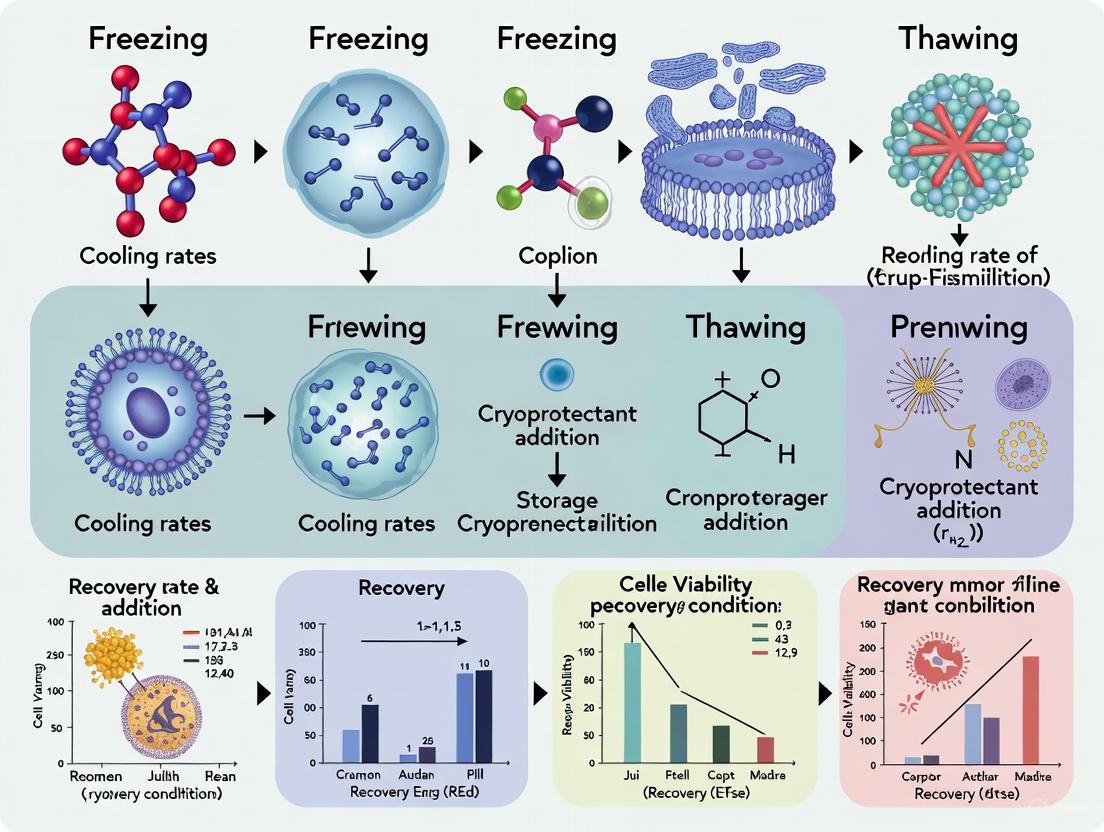

Visualization of Workflows

Cryopreservation Principle: Slow Freezing

Thawing and Recovery Process

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Cell Cryopreservation

| Item | Function & Application |

|---|---|

| Cryoprotective Agents (CPAs) | Protect cells from ice crystal damage and osmotic stress during freeze-thaw. DMSO is the most common penetrating CPA [4]. |

| Serum (e.g., FBS) | Provides proteins and other macromolecules that stabilize cell membranes and reduce ice crystal formation in traditional freezing media [1]. |

| Serum-Free Freezing Media | Chemically defined formulations that eliminate batch-to-batch variability of serum, essential for clinical or regulated applications [1]. |

| Controlled-Rate Freezer | Equipment that ensures a consistent, optimal cooling rate (e.g., -1°C/min), critical for protocol reproducibility and high viability [1] [2]. |

| Isopropanol Freezing Chamber | A passive, cost-effective device that approximates a -1°C/min cooling rate when placed at -80°C, suitable for most cell types [1]. |

| Liquid Nitrogen Storage System | Provides the ultra-low temperatures (<-150°C) required for long-term (years) stable preservation of cell stocks with minimal degradation [5] [2]. |

Cryoprotectants are substances used to protect biological tissue from freezing damage, specifically the formation of ice crystals that can mechanically disrupt cellular membranes and cause lethal increases in solute concentration during the cryopreservation process [4] [6]. The field of cryopreservation began to advance significantly in the mid-20th century when researchers discovered that the addition of cryoprotective agents (CPAs) could dramatically improve cell survival after freezing and thawing [4]. The origins of low-temperature tissue storage research date back to the late 1800s, but the critical breakthrough occurred when glycerol was first successfully used to protect spermatozoa in subfreezing temperatures, followed by the discovery of dimethyl sulfoxide (DMSO) as an effective cryoprotectant in the late 1950s [4] [7].

Cryoprotectants are broadly categorized into two classes: permeating agents (PAs) and non-permeating agents (NPAs). Permeating agents, which include DMSO, glycerol, ethylene glycol, and propylene glycol, are characterized by their relatively small molecular size (typically less than 100 daltons) and amphiphilic nature, allowing them to easily penetrate cell membranes [4]. These agents function primarily by depressing the freezing point of water and promoting vitrification—the formation of an amorphous, glassy solid instead of crystalline ice—through hydrogen bonding with water molecules [4] [6]. Non-permeating agents, such as polyethylene glycol (PEG), sucrose, and trehalose, are typically larger molecules that exert their protective effects extracellularly by inducing vitrification and minimizing osmotic stress [4].

The effectiveness of any cryoprotectant depends on its ability to increase solute concentration within and around cells without exhibiting significant toxicity, a balance that often necessitates using precisely defined concentrations and sometimes mixtures of different cryoprotectants [4] [6]. For decades, cryopreservation protocols relied heavily on fetal bovine serum (FBS) as a medium component, but in recent years, there has been a significant shift toward serum-free formulations due to concerns about variability, contamination risks, and regulatory requirements, particularly for cell-based therapies and biopharmaceutical production [8] [9].

Table 1: Classification of Common Cryoprotectants

| Type | Examples | Molecular Weight | Mechanism of Action | Common Applications |

|---|---|---|---|---|

| Permeating Agents | DMSO, Glycerol, Ethylene Glycol, Propylene Glycol | < 100 Da | Penetrate cell membrane, depress freezing point, promote vitrification | Cell lines, stem cells, sperm, oocytes, embryos [4] |

| Non-Permeating Agents | Trehalose, Sucrose, Raffinose, PEG, PVP | > 100 Da | Remain extracellular, induce vitrification, stabilize membranes | Biopharmaceuticals, sensitive cell types, vitrification mixtures [4] |

Mechanisms of Action and Damage Pathways

Cryoprotectant Mechanisms

Cryoprotectants operate through multiple interconnected mechanisms to protect cells during the freezing and thawing processes. Their primary function is to mitigate the two main theories of freezing damage: (1) the mechanical destruction of cellular membranes by ice crystals, and (2) the lethal increase in solute concentration in the remaining liquid phase as ice forms [4]. Permeating cryoprotectants like DMSO and glycerol readily cross biological membranes and increase the intracellular solute concentration. This depresses the freezing point of water and reduces the amount of water available to form ice crystals, thereby promoting vitrification [4] [6]. The ability of these compounds to form hydrogen bonds with water is crucial to their protective effect, as it interferes with the formation of critical nucleation sites required for crystal formation [4].

DMSO exhibits additional concentration-dependent effects on membrane dynamics. At low concentrations (approximately 5%), it decreases membrane thickness and increases permeability. At standard cryopreservation concentrations (10%), it induces water pore formation in biological membranes, facilitating the replacement of intracellular water with cryoprotectant. However, at high concentrations (40%), it can cause lipid bilayers to disintegrate, demonstrating the narrow window between protection and toxicity [4]. Non-permeating agents operate extracellularly by a similar vitrification mechanism, creating a stable glassy matrix that prevents ice crystal growth and minimizes osmotic shock to cells [4].

Cellular Damage Pathways During Cryopreservation

The journey of cells through cryopreservation exposes them to multiple potential damage pathways that cryoprotectants must address, as illustrated in the diagram below.

Beyond the physical damage from ice crystals, cells face significant challenges from osmotic stress. As extracellular water freezes, solutes become concentrated, creating a hypertonic environment that draws water out of cells, leading to harmful cell shrinkage. During thawing, the reverse process can cause cells to swell and potentially lyse if not properly managed [4]. The cooling and thawing rates are critical factors influencing these damage pathways. Slow cooling rates (approximately 1°C/min) allow sufficient time for water to exit cells before freezing, minimizing intracellular ice formation, but may prolong exposure to concentrated solutes. Rapid cooling can lead to devastating intracellular ice formation [4] [1]. Different cell types require optimized cooling rates; for example, rapid cooling is associated with better outcomes for oocytes and embryonic stem cells, while slow cooling is recommended for hepatocytes and mesenchymal stem cells [4].

Comparative Analysis of DMSO, Glycerol, and Serum-Free Formulations

DMSO (Dimethyl Sulfoxide)

DMSO is one of the most widely used permeating cryoprotectants in research and clinical applications. At the standard concentration of 10% (often corresponding to a 2M solution), DMSO increases the porosity of the cellular membrane, facilitating water movement and helping to prevent the formation of damaging ice crystals by increasing intracellular solute concentration [4]. Its efficacy has been demonstrated across diverse cell types, including stem cells, immune cells, and various primary cells [8] [1].

A key advantage of DMSO is its proven performance in preserving complex tissues. For instance, in a comparative study on human testicular tissue, DMSO at 0.7 mol/l concentration maintained the structure of seminiferous tubules and spermatogonia significantly better than protocols using propanediol or glycerol [10]. However, DMSO is not without limitations. It exhibits concentration-dependent toxicity; at high concentrations, it can disrupt lipid bilayers [4]. Furthermore, concerns have emerged about its potential to induce epigenetic changes and differentiation in certain sensitive cell types, such as stem cells [7]. Clinical side effects, including tonic-clonic seizure and cardiac arrest during infusion of autologous peripheral blood stem cells, have also been reported, though these are often associated with the reinfusion of DMSO-preserved cells rather than the freezing process itself [7].

Glycerol

Glycerol was the first cryoprotectant discovered, successfully used for the cryopreservation of spermatozoa in the late 1940s [4] [6]. It remains a valuable tool, particularly for cell types sensitive to DMSO. Like DMSO, it is a permeating agent that depresses the freezing point and promotes vitrification.

Glycerol's effectiveness can be context-dependent. In a study on rooster semen cryopreservation, DMSO generally performed better than glycerol across various freezing protocols and concentrations [11]. Furthermore, glycerol was found to be severely damaging to the basal compartment of seminiferous tubules in testicular tissue, making it unsuitable for that specific application [10]. Glycerol's permeability varies significantly between cell types, which can sometimes lead to insufficient protection or osmotic damage if not carefully controlled. It is often used as an alternative when DMSO toxicity is a concern or for specific protocols, such as the cryopreservation of certain insect or amphibian cells that naturally produce glycerol as a cryoprotectant [6].

Serum-Free Formulations

The shift toward serum-free cryopreservation media is driven by several critical factors: the need to eliminate batch-to-batch variability inherent in fetal bovine serum (FBS), reduce the risk of contamination by animal-derived pathogens, and align with regulatory standards for clinical applications, particularly in cell therapy and regenerative medicine [8] [9].

Research has demonstrated that well-designed serum-free formulations can match or even surpass the performance of serum-containing media. A 2007 study on vascular cell lines showed that cryopreservation in serum-free solutions specifically formulated for low-temperature storage (Unisol-cryoprotectant vehicle) produced viable cells with retention values up to 75% of unfrozen controls. Crucially, the study concluded that "including serum in the formulation provided no additional benefit to the cells and in some cases actually produced lower cell viability after cryopreservation" [9]. Modern serum-free media are complex, defined solutions that often incorporate a combination of permeating cryoprotectants (like DMSO), non-permeating agents (such as trehalose or sucrose), and other stabilizing components to maintain cell integrity during freeze-thaw cycles [8].

Table 2: Comparative Analysis of DMSO, Glycerol, and Serum-Free Formulations

| Parameter | DMSO | Glycerol | Serum-Free Formulations |

|---|---|---|---|

| Standard Concentration | 5-10% (v/v) [4] [1] | 10% (v/v) [1] | Varies; often includes DMSO + NPAs [8] |

| Mechanism | Permeating agent; induces pore formation [4] | Permeating agent [4] | Combined permeating & non-permeating agents [8] [4] |

| Key Advantages | High efficacy for many cell types; well-established protocols [1] | Lower toxicity for some sensitive cells [1] | Defined composition; reduced variability & contamination risk; regulatory compliance [8] [9] |

| Key Limitations | Potential cytotoxicity; can affect differentiation & epigenetics [7] | Variable permeability; not ideal for all tissues (e.g., testicular) [10] | May require optimization for specific cell types [8] |

| Post-Thaw Viability (Examples) | >90% for MSC in serum-free media [8] | ~71% motility for rooster semen at 15% [11] | Up to 75% viability of unfrozen controls for vascular cells [9] |

| Primary Applications | Stem cells, immune cells, cell therapy, primary cells [8] [1] | Semen (historically), DMSO-sensitive cells [6] [11] | Cell therapy manufacturing, biopharmaceuticals, clinical applications [8] |

Application Notes and Protocols

Standard Mammalian Cell Cryopreservation Protocol

The following protocol outlines a standardized, controlled-rate method for cryopreserving mammalian cells, adaptable to both serum-containing and serum-free media. This protocol is designed to maximize post-thaw viability and functionality for a wide range of adherent and suspension cell types [1].

Principle: Cryopreservation at a controlled cooling rate of -1°C/minute minimizes intracellular ice crystal formation by allowing sufficient water efflux from cells before freezing. The addition of a cryoprotectant (DMSO or glycerol) further protects cells by promoting vitrification [4] [1].

Materials:

- Cryopreservation Media (See Table 1 in Section 4.2 for formulations)

- 1-2 mL sterile cryovials

- Controlled-rate freezing device (e.g., CoolCell or programmable freezer)

- Liquid nitrogen storage tank

- -80°C freezer

Procedure:

- Cell Preparation: Harvest cells during their optimal growth phase (typically logarithmic phase). For adherent cells, wash with PBS, dissociate with trypsin, and neutralize with culture media. For suspension cells, proceed directly to centrifugation [1].

- Viability and Counting: Count cells using a hemocytometer or automated counter. Ensure cell viability is at least 75% before cryopreservation [1].

- Centrifugation: Centrifuge the cell suspension at 300 x g for 5 minutes at room temperature. Carefully aspirate the supernatant [1].

- Resuspension in Cryomedium: Loosen the cell pellet gently. Resuspend cells in pre-chilled cryopreservation media at a density of 1 x 10^6 to 1 x 10^7 cells/mL. Gently mix to ensure a uniform suspension. Note: Cells should not remain in cryomedium containing DMSO at room temperature for more than 10 minutes to minimize toxicity [1].

- Aliquoting: Dispense 1 mL of the cell suspension into each labeled cryovial. Seal the vials tightly.

- Controlled-Rate Freezing: Place the cryovials into a controlled-rate freezing device (e.g., CoolCell) and immediately transfer to a -80°C freezer for 24 hours. The device will ensure a consistent cooling rate of approximately -1°C/minute [1].

- Long-Term Storage: After 24 hours, promptly transfer the cryovials to the vapor or liquid phase of a liquid nitrogen storage system (-135°C to -196°C) for long-term preservation. Avoid prolonged storage at -80°C, as this can reduce viability [1].

Quality Control:

- Post-Thaw Analysis: Always assess the viability and functionality of a representative vial after thawing. This can include trypan blue exclusion for viability, flow cytometry for specific markers, and functional assays (e.g., differentiation potential for stem cells, secretion for production cells) [4].

- Record Keeping: Maintain detailed records including passage number, date frozen, cell density, viability pre-freeze and post-thaw, and the specific cryomedium formulation used.

Formulation-Specific Considerations

Table 3: Cryopreservation Media Formulations for Different Culture Systems

| Culture Type | Freezing Media Formulation | Notes & Considerations |

|---|---|---|

| Cells in FBS-containing Media | 90% FBS + 10% DMSO [1] | Traditional method; provides undefined nutrients and proteins. High protein content may interfere with downstream applications. |

| Cells in Serum-Free Media | 90% conditioned media + 10% DMSO OR Commercial serum-free cryomedium [1] | Conditioned media is the supernatant from the centrifugation step. Commercial serum-free media are optimized for defined components and regulatory compliance [8]. |

| Glycerol-Sensitive Cells | 90% FBS + 10% Glycerol [1] | Glycerol permeates more slowly than DMSO for some cell types; requires careful optimization of equilibration and thawing times. |

| Advanced Serum-Free Formulations | Defined base (e.g., RPMI, DMEM) + 10% DMSO + Non-permeating agents (e.g., trehalose, sucrose) + Synthetic polymers [8] [7] | Designed for high recovery and consistent performance in regulated environments like cell therapy manufacturing [8]. |

Thawing and Recovery Protocol

The thawing process is as critical as freezing for maintaining cell viability. Rapid thawing is essential to minimize the time cells are exposed to the cytotoxic effects of DMSO and to prevent the growth of small, damaging ice crystals (recrystallization) during the phase transition [1].

Procedure:

- Rapid Thaw: Remove the cryovial from liquid nitrogen and immediately place it in a 37°C water bath. Gently agitate the vial until only a small ice crystal remains (approximately 80% thawed). This should take no longer than 1-2 minutes. Do not thaw at room temperature or submerge the vial cap. [1]

- Dilution and Cryoprotectant Removal: Immediately after thawing, decontaminate the vial with 70% ethanol. Using a pipette, gently transfer the cell suspension to a 15 mL conical tube containing 10 mL of pre-warmed complete culture medium. This step rapidly dilutes the cryoprotectant [1].

- Centrifugation: Centrifuge the cell suspension at 300 x g for 5 minutes to pellet the cells and remove the cryoprotectant-containing supernatant [1].

- Resuspension and Culture: Discard the supernatant, gently resuspend the cell pellet in fresh, pre-warmed culture medium, and transfer the cells to an appropriate culture vessel. Place the vessel in a 37°C, 5% CO₂ incubator [1].

- Post-Thaw Assessment: Assess cell viability 24 hours post-thaw to allow for recovery. For sensitive applications (e.g., cell therapy), functional assays should be performed to confirm the retention of critical biological activity [8] [4].

Applications in Research and Drug Development

The selection and optimization of cryoprotectants are pivotal across numerous fields, from basic research to advanced clinical applications. The following workflow outlines the key decision points for selecting and applying cryoprotectants in a research and development pipeline.

Cell Therapy Manufacturing: This area demands the highest standards for cryoprotectant selection. Serum-free, xeno-free formulations are essential for regulatory compliance and patient safety. These formulations are designed to preserve not only viability (>90% for mesenchymal stem cells) but also critical therapeutic functions, such as differentiation potential and secretory profile, post-thaw [8]. Consistency is paramount, as variability in cryopreservation can directly impact clinical outcomes.

Biopharmaceutical Production: The production of therapeutic proteins relies on stable, consistent cell banks. Serum-free cryopreservation of production cell lines (e.g., CHO cells) ensures reproducible yields and reduces the risk of batch failures caused by serum variability or contamination. Adopting serum-free media has been reported to increase post-thaw productivity by 15-20% compared to serum-based methods [8].

Regenerative Medicine and Advanced Therapies: Cryopreservation of delicate cell types like induced pluripotent stem cells (iPSCs) and embryonic stem cells (ESCs) requires specialized protocols to maintain their pluripotent state. Serum-free media are critical here, as serum can introduce uncontrolled differentiation signals. Optimized protocols can achieve viability rates exceeding 90% while preserving pluripotency markers and differentiation capacity, which is essential for tissue engineering and transplantation applications [8].

Research and Biobanking: In academic and industrial research, serum-free cryopreservation minimizes experimental variability, leading to more reliable and reproducible results. For biobanking of clinical samples (e.g., blood, tissue biopsies), serum-free media ensure sample integrity for future diagnostic analysis and eliminate the risk of contamination by animal components, which is critical for downstream genomic or proteomic analyses [8].

The Scientist's Toolkit: Essential Reagents and Materials

Successful cryopreservation relies on a suite of specialized reagents and equipment. The following table details key solutions and tools essential for implementing robust cryopreservation protocols.

Table 4: Essential Research Reagents and Solutions for Cryopreservation

| Tool/Solution | Function/Description | Application Notes |

|---|---|---|

| DMSO (Dimethyl Sulfoxide) | Permeating cryoprotectant; standard concentration 5-10% [4] [1]. | Use high-grade, sterile-filtered DMSO. Hyroscopic; store properly. Add to media just before use to avoid precipitation. |

| Glycerol | Permeating cryoprotectant; standard concentration 10% [1] [6]. | An alternative to DMSO for sensitive cells. Sterilize by autoclaving or filtration. |

| Serum-Free Cryopreservation Media | Defined, animal-origin-free media for clinical & sensitive research applications [8]. | Available from vendors (e.g., Thermo Fisher, STEMCELL Tech). Formulations are often cell type-specific (e.g., for T-cells, MSC). |

| Trehalose | Non-permeating disaccharide cryoprotectant; stabilizes membranes & proteins [4]. | Often used in combination with permeating CPAs to reduce their toxic concentration. |

| Controlled-Rate Freezer (e.g., CoolCell) | Device ensuring consistent cooling rate (~-1°C/min) critical for high viability [1]. | Passive devices (CoolCell) are placed in a -80°C freezer. Active, programmable freezers offer more flexibility. |

| Liquid Nitrogen Storage System | Provides long-term storage at -135°C (vapor) to -196°C (liquid) [1]. | Liquid phase offers lower temperature but risk of explosion if vial seal fails. Vapor phase is safer for routine storage. |

| Cryovials | Specially designed tubes for low-temperature storage; typically 1-2 mL capacity. | Use internally-threaded vials for superior seal and to prevent liquid nitrogen ingress during storage. |

The field of cryopreservation is evolving beyond the conventional use of DMSO and glycerol. Research is increasingly focused on the development of advanced cryoprotectant mixtures that reduce toxicity by combining multiple agents at lower individual concentrations [6] [7]. Furthermore, bio-inspired approaches are gaining traction, such as the use of antifreeze proteins and cryoprotectants like trehalose, which are produced naturally by extremophiles to withstand freezing conditions [6] [7].

Emerging technologies are also poised to transform cryopreservation workflows. Vitrification, the process of solidifying water into a glassy state without ice crystallization, is being advanced for complex tissues and organs using high concentrations of cryoprotectant cocktails [6] [7]. Novel warming techniques, such as inductive heating of magnetic nanoparticles, address the challenge of achieving rapid and uniform warming, which is critical for the success of vitrification [7]. The integration of library-based discovery approaches and materials science is enabling the high-throughput screening and design of new polymeric cryoprotectants and ice-binding inhibitors [7].

The judicious selection and application of cryoprotectants—spanning the established efficacy of DMSO, the utility of glycerol, and the modern advantages of serum-free formulations—are foundational to successful cell preservation. The optimal cryopreservation strategy is not one-size-fits-all; it must be tailored to the specific cell type, application, and regulatory context. As the demand for cell-based therapies and biopharmaceuticals continues to grow, the adoption of defined, serum-free cryopreservation media is expected to become the standard, driven by the imperative for consistency, safety, and regulatory compliance. The future of cryopreservation lies in the intelligent design of next-generation cryoprotectants and protocols that further minimize damage, enhance recovery, and enable the long-term preservation of increasingly complex biological systems.

Within the broader context of cell freezing and thawing protocol research, the steps taken prior to the freezing process are critical determinants of post-thaw cell viability, functionality, and experimental reproducibility. Cryopreservation is not merely a pause button for cells; it is a stressful event that only healthy, optimally prepared cultures can withstand without significant loss. For researchers, scientists, and drug development professionals, establishing robust pre-freeze checkpoints is a non-negotiable standard for ensuring the integrity of cell banks and the reliability of downstream applications, from basic research to cell-based therapies. This application note details the essential pre-freeze assessments—cell health, confluency, and contamination status—providing structured protocols and data to standardize this vital preparatory phase.

Key Pre-Freeze Checkpoints

A successful cryopreservation outcome hinges on verifying three key cellular conditions immediately before freezing. The quantitative targets for these checkpoints are summarized in Table 1.

Table 1: Quantitative Pre-Freeze Checkpoint Targets

| Checkpoint | Optimal Target / Status | Critical Thresholds & Notes |

|---|---|---|

| Cell Health & Growth Phase | Logarithmic (log) growth phase [12] [13] [1] | High viability (>75% [1], ideally >90% [13]) is required. Cells should be passaged 1-2 days before freezing [14] [15]. |

| Cell Confluency | 70-80% for most adherent cells [16] [17] [13] | Avoid overconfluency (>80-100%) to prevent stress, death, and spontaneous differentiation [16] [12] [17]. |

| Contamination Status | Confirmed absence of microbial contamination [12] [13] | Check for media turbidity, unexpected color change, or morphological changes in cells [13]. Conduct mycoplasma testing [13]. |

Checkpoint 1: Cell Health and Growth Phase

Rationale: Cells must be in a robust state of health to survive the rigors of cryopreservation. Harvesting cells during their logarithmic growth phase ensures maximum metabolic activity and health, which is a strong predictor of post-thaw recovery [12] [13] [1]. Cells in this phase are most resilient, while those in the stationary or decline phase have a significantly reduced capacity to withstand freezing stress.

Experimental Protocol: Assessing Growth Phase and Viability

- Method: Perform a cell count and viability assay 1-2 days after the last passaging, immediately before the freezing procedure [14] [15].

- Procedure:

- Harvest Cells: Detach adherent cells using a standard method (e.g., trypsin/EDTA) or collect suspension cells [1].

- Prepare Cell Suspension: Resuspend cells in an appropriate culture medium [1].

- Count and Assess Viability: Mix the cell suspension with Trypan Blue (or an equivalent dye) and load it into a hemocytometer [18] [1]. Viable cells will exclude the dye, while non-viable cells will take it up.

- Calculation: Calculate the total cell count and the percentage of viable cells. Proceed with cryopreservation only if viability exceeds 75% [1], though ideally it should be >90% [13].

Checkpoint 2: Cell Confluency

Rationale: Cell confluency is the percentage of the culture vessel surface area covered by adherent cells [16] [17]. It is a crucial parameter that helps determine the timing for passaging and cryopreservation [16]. Overconfluency can lead to nutrient depletion, contact inhibition, competition for physical space, and even the onset of spontaneous differentiation in sensitive cell types like stem cells and preadipocytes [16] [17]. This state dramatically increases cell stress and death upon thawing [17]. Conversely, freezing cells at too low a confluency can also yield suboptimal results.

Experimental Protocol: Measuring Confluency Method 1: Qualitative Visual Estimation (Common but Subjective)

- Procedure: Visually inspect the cell monolayer under a standard phase-contrast microscope and estimate the percentage of the surface area covered [16] [17].

- Reference Guidelines:

- 50% Confluent: The area covered by cells is roughly equal to the area not covered by cells [17].

- 70-80% Confluent: The surface is mostly covered, but clear gaps between cells are still visible. This is the ideal range for freezing most cell types [16] [17] [13].

- 100% Confluent: The entire surface is covered by cells with no visible gaps between them [17].

Method 2: Automated Image Analysis (Accurate and Reproducible)

- Procedure: Use integrated imaging systems (e.g., EVOS M3000 Imaging System, Olympus CKX53 with confluency software) that capture images and automatically calculate the percentage of area covered by cells using thresholding and edge-detection algorithms [16] [17]. This method eliminates inter-researcher variability.

Checkpoint 3: Contamination Status

Rationale: Cryopreserving a contaminated culture is tantamount to preserving the contaminant, leading to the irreversible loss of the cell line and potential cross-contamination of other stocks. Microbial contamination (e.g., bacteria, fungi, mycoplasma) can deplete nutrients, alter cell metabolism, and induce cell death [16] [13].

Experimental Protocol: Assessing Contamination Status

- Method 1: Visual and Microscopic Inspection

- Method 2: Mycoplasma Testing

- Procedure: Given that mycoplasma contamination is not visible under a standard microscope, it is recommended to implement regular testing using commercially available PCR-based detection kits or enzymatic assays as part of the pre-freeze workflow, especially for master cell banks [13].

- Aseptic Technique: During all handling steps, use proper aseptic technique, including wiping down all containers with 70% ethanol or isopropanol before opening them inside a biosafety cabinet [18] [13].

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents and Materials for Pre-Freeze Assessment

| Item | Function & Application |

|---|---|

| Hemocytometer | A specialized slide with a grid for manually counting cells and assessing population density [18]. |

| Trypan Blue | A vital dye used to distinguish between viable and non-viable cells during counting; non-viable cells with compromised membranes take up the blue stain [18] [1]. |

| Phase-Contrast Microscope | Essential for the visual inspection of cell morphology, confluency estimation, and initial checks for gross microbial contamination [16] [17]. |

| Automated Cell Counter | Instrument that automates cell counting and viability analysis, improving speed and reducing subjectivity compared to manual methods. |

| Mycoplasma Detection Kit | A dedicated test (e.g., PCR-based) to identify the presence of mycoplasma, a common and invisible cell culture contaminant [13]. |

| Cell-Freezing Medium | A specialized solution, often containing cryoprotectants like DMSO and FBS, designed to protect cells from freezing damage [14] [13] [1]. |

Integrated Workflow

The following diagram illustrates the logical sequence and decision points for the key pre-freeze checkpoints.

Logical Workflow for Pre-Freeze Checkpoints

The success of modern cell-based therapies, regenerative medicine, and biomedical research hinges on the ability to reliably preserve living cells without compromising their viability or biological function. The fundamental challenge of cryopreservation lies in navigating the complex thermodynamics of water phase changes at sub-zero temperatures. Intracellular ice crystallization is overwhelmingly lethal to cells, causing mechanical destruction of cellular membranes and organelles [19] [4]. Consequently, the core principles of cryopreservation focus on understanding and controlling the transition of water from liquid to solid states—either through crystalline formation or vitrification—to mitigate these damaging effects [20]. This application note examines the thermodynamic principles of glass transition and crystallization, detailing practical protocols designed to prevent intracellular ice formation and ensure high post-thaw cell viability and functionality for research and therapeutic applications.

Theoretical Foundations: Thermodynamics of Freezing

Ice Crystallization and Its Cellular Consequences

During freezing, the formation of ice crystals poses two primary mechanical threats to cells. First, extracellular ice formation mechanically crushes cells and creates osmotic imbalances. Second, intracellular ice crystals physically disrupt organelles and pierce the plasma membrane, which is almost always lethal [19] [4]. The energy dynamics of this process are critical; as water freezes, the latent heat of fusion is released, which can cause a temperature spike if not properly managed during controlled-rate freezing [20].

The nucleation of ice crystals can be described by the critical radius r, the minimum size a crystal nucleus must reach for spontaneous growth to occur. This radius is given by: [r = - {{2\gamma } \over {\Delta {Sv}\Delta T}}] where γ is the interfacial energy per unit area, and ΔSvΔT is the free energy of solidification per unit volume. Consequently, nucleation occurs when the supercooling ΔT satisfies: [\Delta T \ge - {{2\gamma } \over {\Delta {S_v}R}}] where R is the radius of an ice nucleating agent [19]. This relationship demonstrates that larger nucleating agents require smaller supercooling for ice formation to initiate.

The Glass Transition and Vitrification

Vitrification represents a fundamentally different approach to solidification, where water transitions into an amorphous, glass-like state without forming ice crystals. This process is achieved through rapid cooling and/or high concentrations of cryoprotective agents (CPAs), dramatically increasing solution viscosity until molecular motion effectively ceases [20] [4].

The glass transition point is the critical temperature at which this amorphous solid forms, typically ranging between -100°C and -130°C for cryopreservation solutions [21]. Below this temperature, biological time effectively stops, enabling indefinite storage. In contrast, the vitrification point refers to the specific conditions (combining CPA concentration and cooling rate) under which this glassy state is achieved without ice crystallization [21]. For biological samples containing cells or tissues, storage must occur below the glass transition temperature to ensure long-term stability [20].

Table 1: Critical Temperature Transitions in Cryopreservation

| Transition Point | Definition | Typical Temperature Range | Impact on Cells |

|---|---|---|---|

| Nucleation Point | Initial stage of ice crystal formation | -5°C to -10°C [21] | Ice crystals cause mechanical damage and osmotic stress [21] |

| Glass Transition (Tg) | Transition to amorphous glassy state | -100°C to -130°C [21] | Halts biochemical processes; enables long-term storage [20] |

| Vitrification Point | Achieves glassy state without ice formation | Below -120°C [21] | Minimizes cellular damage; maintains viability [21] |

Essential Concepts for Preventing Intracellular Ice

Cryoprotectant Mechanisms

Cryoprotective Agents (CPAs) are essential components of freezing media that protect cells through multiple mechanisms [4]:

- Depressing Ice Nucleation: CPAs lower the freezing point of the solution and reduce the amount of ice formed at any given temperature.

- Promoting Glass Transition: They facilitate the transition to a glassy state at higher temperatures.

- Reducing Cell Shrinkage: By modulating osmotic pressure, CPAs minimize deleterious cell dehydration during slow freezing.

- Stabilizing Membranes and Proteins: Some CPAs directly interact with cellular structures to maintain their integrity.

CPAs are categorized as permeating or non-permeating based on their ability to cross cell membranes. Permeating agents (e.g., DMSO, glycerol) enter cells and protect against intracellular ice formation, while non-permeating agents (e.g., sucrose, trehalose) exert their effects extracellularly, often enabling reduced concentrations of toxic permeating agents [4].

Cooling Rate Optimization

The cooling rate is a critical parameter that determines the balance between intracellular ice formation and osmotic dehydration damage. Different cell types have unique optimal cooling rates based on their membrane permeability and volume [4].

- Slow Cooling (≈1°C/min): Allows water to exit the cell before freezing, minimizing intracellular ice but potentially causing excessive dehydration [13] [4].

- Rapid Cooling (Vitrification): Prevents water efflux, resulting in vitrification rather than ice crystallization, but requires high CPA concentrations [20] [22].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 2: Key Reagents and Equipment for Cryopreservation Research

| Item | Function/Application | Examples/Specifications |

|---|---|---|

| Permeating Cryoprotectants | Penetrate cell membranes to prevent intracellular ice [4] | DMSO, Glycerol, Ethylene Glycol [4] |

| Non-Permeating Cryoprotectants | Act extracellularly; enable CPA concentration reduction [4] | Sucrose, Trehalose, Polyethylene Glycol (PEG) [4] |

| Optimized Freezing Media | Ready-to-use, defined formulations for specific cell types [13] | CryoStor CS10, mFreSR for pluripotent stem cells [13] |

| Controlled-Rate Freezer | Precisely manages cooling rate (typically -1°C/min) [13] [23] | Liquid nitrogen or electric cryocooling models [20] [23] |

| Passive Cooling Devices | Provides approximate cooling rate when CRF unavailable [13] | Nalgene Mr. Frosty, Corning CoolCell [13] |

| Cryogenic Storage Vials | Secure containment for long-term storage [13] | Internal-threaded vials; sterilized [13] |

| Liquid Nitrogen Storage | Long-term storage below glass transition (-135°C to -196°C) [13] [20] | Liquid or vapor phase nitrogen systems [13] |

Experimental Protocols

Protocol: Controlled-Rate Freezing for Mononuclear Cells

This standardized protocol is optimized for cell types such as Peripheral Blood Mononuclear Cells (PBMCs) and mesenchymal stromal cells, which benefit from slow cooling rates [13] [4].

Materials:

- Cryopreservation medium: CryoStor CS10 or equivalent containing 10% DMSO [13]

- Sterile cryogenic vials

- Controlled-rate freezer or passive freezing container

- Programmable water bath (37°C) or automated thawing device

Method:

- Harvesting and Preparation: Harvest cells during logarithmic growth phase at >80% confluency. Gently centrifuge to pellet cells and remove supernatant [13].

- CPA Addition: Resuspend cell pellet in pre-chilled (4°C) cryopreservation medium to a final concentration of 1x10^6 to 5x10^6 cells/mL. Gently mix to ensure uniform CPA exposure [13].

- Aliquoting: Dispense 1-2 mL of cell suspension into each cryogenic vial. Keep vials on wet ice to maintain temperature stability during CPA exposure [13].

- Controlled-Rate Freezing:

- Using Controlled-Rate Freezer: Place vials in chamber and initiate program:

- Using Passive Container: Place vials in isopropanol freezing container and transfer immediately to -80°C freezer for 18-24 hours [13].

- Long-Term Storage: Transfer vials to liquid nitrogen storage (-135°C to -196°C) for long-term preservation [13].

- Thawing and Assessment: Rapidly thaw vials in 37°C water bath with gentle agitation until only a small ice crystal remains. Immediately transfer to pre-warmed culture medium and assess viability and vitality [13] [21].

Protocol: Vitrification of Sensitive Cell Types

This method is particularly suitable for oocytes, embryos, and induced pluripotent stem cells (iPSCs) that are highly sensitive to CPA toxicity and ice crystal damage [24] [22].

Materials:

- Vitrification solution: Combination of permeating (e.g., DMSO, ethylene glycol) and non-permeating (e.g., sucrose) CPAs [4]

- Open or closed vitrification devices

- Liquid nitrogen for rapid cooling

Method:

- Equilibration: Expose cells to lower concentration CPA solution (e.g., 2-4 M permeating CPA) for 10-15 minutes at room temperature to permit partial dehydration and CPA penetration [4].

- Vitrification Solution Exposure: Transfer cells to high concentration vitrification solution (e.g., 6-8 M total CPAs with sucrose) for <60 seconds at room temperature [4].

- Rapid Cooling: Quickly load cells in minimal volume onto vitrification device and directly plunge into liquid nitrogen, achieving cooling rates >20,000°C/min [4].

- Storage and Thawing: Store in liquid nitrogen. For thawing, rapidly warm and sequentially transfer through decreasing CPA concentrations to remove CPAs and prevent osmotic shock [4].

Quantitative Data for Protocol Optimization

Table 3: Cell-Type Specific Cryopreservation Parameters and Outcomes

| Cell Type | Recommended Cooling Rate | Recommended CPA | Post-Thaw Viability Target | Key Functional Assays |

|---|---|---|---|---|

| Hepatocytes | Slow cooling [4] | 10% DMSO [4] | >80% [25] | Albumin secretion, drug metabolism [4] |

| Pancreatic Islets | Rapid cooling [4] | Vitrification mixtures [4] | >85% [25] | Glucose-stimulated insulin release [4] |

| Stem Cells (MSCs, HSCs) | Slow cooling (-1°C/min) [4] | 10% DMSO [13] [4] | >80% [25] | Differentiation potential, surface markers [21] |

| Oocytes | Rapid cooling (vitrification) [4] | EG/DMSO/sucrose [4] | >90% [24] | Fertilization rates, embryonic development [24] |

| CAR-T Cells | Controlled-rate freezing [23] | DMSO-containing [23] | >80% [25] | Cytokine release, tumor killing [23] |

Workflow and Thermodynamic Pathways

The following diagram illustrates the critical decision points in a cryopreservation protocol based on thermodynamic principles, guiding researchers toward either the crystalline or vitrification pathway.

Diagram 1: Thermodynamic Decision Pathway in Cryopreservation. This workflow outlines the critical branching points where cooling rate and CPA concentration determine whether cells follow the path of crystalline ice formation with dehydration or achieve a vitrified state.

Mastering the thermodynamics of freezing—specifically the interplay between glass transition, ice crystallization, and intracellular ice prevention—is fundamental to advancing cell-based research and therapies. The protocols and principles detailed in this application note provide a framework for optimizing cryopreservation outcomes based on cell-specific requirements. As the field progresses toward more complex cellular products, including engineered tissues and organoids, further refinement of these thermodynamic approaches will be essential. Future developments will likely focus on reducing CPA toxicity through improved vitrification mixtures, standardizing protocols across cell types, and enhancing monitoring techniques during the freezing process to ensure both high viability and preserved cellular functionality post-thaw.

Step-by-Step Protocols: From Log-Phase Harvest to Long-Term Liquid Nitrogen Storage

Within the comprehensive framework of cell freezing and thawing research, the pre-freeze preparation phase is critically important for ensuring high post-thaw viability and functionality. This stage establishes the foundational condition of cells before they undergo the stresses of cryopreservation. Two parameters are paramount: harvesting cells during their logarithmic growth phase (log phase) and resuspending them at an optimal concentration in cryopreservation medium. Neglecting these factors can lead to poor recovery, reduced viability, and experimental inconsistencies, ultimately compromising the value of cryopreserved cell stocks [26] [13]. This application note provides detailed protocols and best practices for these crucial pre-freeze steps, equipping researchers and drug development professionals with the methodologies needed to create high-quality, reproducible cell banks.

The Critical Importance of Log Phase Harvesting

Log phase, also known as the exponential growth phase, represents the period when cells are actively dividing and are at their peak metabolic health. Cells harvested during this period typically have >90% viability and are most resilient to the stresses of cryopreservation, including dissociation, centrifugation, and exposure to cryoprotectants like DMSO [26] [27]. Using log-phase cells for freezing leads to superior attachment and growth post-thaw, faster recovery, and more reliable experimental outcomes.

The primary rationale for this practice is the prevention of genetic drift and phenotypic changes. Continuous passaging of cells beyond their log phase can lead to senescence, genetic drift, and potential transformation, especially in finite cell lines [26]. Cryopreservation acts as a "pause button," suspending cellular metabolism. By freezing cells at their healthiest, their genetic integrity and functionality are preserved for future use. For adherent cultures, this means harvesting at 80-95% confluence, while suspension cultures should be harvested when the cell density is high but before the growth medium is exhausted [13] [28].

Table 1: Indicators of Log Phase for Different Culture Types

| Culture Type | Visual & Metabolic Indicators | Recommended Harvest Point |

|---|---|---|

| Adherent Cells | - Cells are actively dividing and mitotic figures may be visible.- Culture is sub-confluent (not 100% covered).- Medium is not exhausted (normal color).- Cells exhibit characteristic, healthy morphology. | 80-95% confluence [28] |

| Suspension Cells | - Cell density is increasing exponentially.- Culture medium has not shifted significantly in color/pH.- Viability is high (>90%) as determined by trypan blue exclusion. | Before maximum density is reached; while viability is >90% [27] |

Determining Optimal Cell Concentration for Freezing

Resuspending the cell pellet at the correct concentration in freezing medium is equally critical. A concentration that is too low can lead to poor recovery and viability after thawing, as a minimum cell density is often required for effective cell signaling and growth. Conversely, a concentration that is too high can promote undesirable cell clumping and exhaust the cryoprotectant, reducing its protective efficacy [13].

The optimal cell concentration is cell-type dependent. Researchers are advised to test a range of concentrations to determine the ideal density for their specific cell line. The general range for most mammalian cells is between 1x10^3 and 1x10^6 cells/mL, though many common cell types fall within a narrower window [13].

Table 2: General Guidelines for Cell Freezing Concentrations

| Cell Type | Typical Freezing Concentration | Notes & Considerations |

|---|---|---|

| Adherent Cells (general) | 1-5 x 10^6 cells/mL [28] [27] | A common starting point is ~2 x 10^6 cells/mL [28]. |

| Suspension Cells (general) | 5-10 x 10^6 cells/mL [27] | A common starting point is ~5 x 10^6 cells/mL [28]. |

| PBMCs | 5-25 x 10^6 cells/mL [29] | Concentration can be adjusted based on experimental needs and volume constraints. |

| Stem Cells (e.g., hPSCs) | Cell-type specific | Use specialized freezing media and follow vendor-recommended concentrations, which can vary [13]. |

Experimental Protocols

Protocol 1: Harvesting Adherent Cells in Log Phase

This protocol describes the process for harvesting adherent mammalian cells, such as HEK293 or HeLa, prior to cryopreservation.

Research Reagent Solutions & Materials

- Complete Growth Medium: Pre-warmed to 37°C [26].

- Balanced Salt Solution (e.g., DPBS): Without calcium or magnesium, sterile [26].

- Dissociation Reagent (e.g., Trypsin, TrypLE): Without phenol red, sterile [26] [28].

- Trypan Blue Solution (0.4%): For viability staining and cell counting [27].

- Hemocytometer or Automated Cell Counter [26].

- Centrifuge and Sterile Conical Tubes [26].

Methodology

- Preparation: Visually inspect the culture under a microscope. Confirm that cells are healthy, display normal morphology, and are at 80-95% confluence [28]. Ensure all reagents are pre-warmed and work under sterile conditions in a laminar flow hood.

- Aspiration: Carefully aspirate and discard the spent culture medium from the tissue culture vessel.

- Rinsing: Gently add a sufficient volume of pre-warmed DPBS to wash the cell monolayer. Swirl gently and aspirate the PBS. This step removes residual serum that can inhibit trypsin.

- Dissociation: Add enough pre-warmed dissociation reagent (e.g., TrypLE) to cover the monolayer. Incubate the vessel at 37°C for the time specified for the cell line (typically 2-5 minutes) [28].

- Neutralization: Firmly tap the vessel to dislodge the cells. Under microscopic examination, most cells should be detached and rounded. Add a volume of complete growth medium (containing serum) that is at least equal to the volume of dissociation reagent used to neutralize the reaction.

- Collection: Pipette the cell suspension over the surface of the vessel to collect any remaining cells and transfer the entire suspension to a sterile conical tube.

- Cell Counting: Perform a viable cell count using trypan blue exclusion and a hemocytometer or automated cell counter [26] [27]. Mix 10-20 µL of cell suspension with an equal volume of 0.4% trypan blue. Load onto a hemocytometer and count unstained (viable) and blue-stained (non-viable) cells. Calculate total and viable cell concentration.

Protocol 2: Harvesting Suspension Cells in Log Phase

This protocol is for harvesting non-adherent mammalian cells, such as Jurkat or HL-60 cells.

Research Reagent Solutions & Materials

- Complete Growth Medium [26].

- Trypan Blue Solution (0.4%) [27].

- Hemocytometer or Automated Cell Counter [26].

- Centrifuge and Sterile Conical Tubes [26].

Methodology

- Preparation: Gently mix the suspension culture to ensure a homogeneous cell distribution. Take a small sample for a viability count. Confirm the cells are in log phase by high viability (>90%) and increasing cell density [27].

- Collection: Transfer the entire cell suspension to a sterile conical tube.

- Centrifugation: Centrifuge the tube at 200-400 x g for 5-10 minutes at room temperature to pellet the cells [26] [27].

- Supernatant Removal: Carefully decant or aspirate the supernatant without disturbing the cell pellet.

- Resuspension: Gently tap the tube to loosen the pellet. Resuspend the cells in a small volume of fresh, pre-warmed complete growth medium by pipetting up and down slowly.

- Cell Counting: Perform a viable cell count as described in Protocol 1, Step 7.

Protocol 3: Determining Concentration and Preparing for Freezing

This final protocol covers calculating the required volume of freezing medium and preparing the cell suspension for aliquoting.

Research Reagent Solutions & Materials

- Freezing Medium: Pre-chilled (2-8°C). This can be a commercial, serum-free formulation (e.g., CryoStor) or a lab-made medium (e.g., 90% FBS + 10% DMSO) [26] [28].

- Sterile Cryogenic Vials [26].

- Pipettes and sterile tips.

Methodology

- Centrifugation: Centrifuge the harvested cell suspension (from Protocol 1 or 2) at 200-400 x g for 5-10 minutes [26]. Aspirate the supernatant completely.

- Concentration Calculation: Based on the viable cell count and the target freezing concentration (refer to Table 2), calculate the volume of freezing medium required.

- Volume of Freezing Medium (mL) = Total number of viable cells / Desired concentration (cells/mL)

- Resuspension in Freezing Medium: Gently tap the tube to loosen the cell pellet. Slowly add the calculated, pre-chilled volume of freezing medium to the pellet. Gently resuspend the cells using a pipette to achieve a homogeneous suspension. Work efficiently but avoid creating bubbles.

- Aliquoting: Quickly aliquot the cell suspension into pre-labeled cryogenic vials. Gently mix the main cell suspension frequently during aliquoting to ensure consistency across vials [26].

- Immediate Freezing: Transfer the filled cryovials to a controlled-rate freezing apparatus (e.g., "Mr. Frosty" or a programmable freezer) and place it in a -80°C freezer immediately. Do not delay, as cells are sensitive to extended exposure to cryoprotectants like DMSO at room temperature [29].

The workflow below summarizes the key decision points and steps in the pre-freeze preparation process.

Cryopreservation is a vital process in biological research and clinical applications, enabling the long-term storage of cells while maintaining their viability and functionality. The choice of freezing media is a critical determinant of post-thaw cell recovery and experimental reproducibility. This application note provides a detailed comparison between standard laboratory-prepared formulations and commercial serum-free alternatives, offering evidence-based protocols for researchers and drug development professionals working within the context of cell freezing and thawing optimization.

The transition from traditional serum-containing media to defined serum-free formulations addresses several challenges, including batch-to-batch variability, ethical concerns, and the risk of pathogen transmission associated with fetal bovine serum (FBS) [30] [31]. Commercial serum-free media offer standardized, ready-to-use solutions designed to provide consistent performance across diverse cell types and applications, from basic research to clinical cell therapy manufacturing.

Comparative Analysis: Formulations and Performance

Composition and Characteristics

Table 1: Key Components and Characteristics of Freezing Media Types

| Component/Characteristic | Standard Formulations | Commercial Serum-Free Media |

|---|---|---|

| Base Medium | Culture medium (e.g., RPMI, DMEM) [32] | Proprietary, chemically defined base [33] [13] |

| Protein Source | 10-90% Fetal Bovine Serum (FBS) [32] | Animal-derived protein-free or recombinant human proteins [30] [13] |

| Cryoprotectant | 10% DMSO, sometimes 10% glycerol [32] | Typically 10% DMSO; some with reduced DMSO or alternative agents [30] [34] |

| Regulatory Status | Laboratory-grade, often not suitable for therapeutics | Often manufactured under cGMP for clinical applications [13] |

| Key Advantage | Low cost, lab-specific customization | Defined composition, lot-to-lot consistency, reduced contamination risk [33] [31] |

| Primary Limitation | Serum variability, undefined components, immunogenicity risk | Higher cost, may require cell-specific optimization [33] |

Quantitative Performance Data

Recent comparative studies provide quantitative evidence of the performance of commercial serum-free media against standard FBS-based formulations.

Table 2: Performance Comparison in PBMC Cryopreservation (2-Year Study) [30] [31]

| Freezing Medium | DMSO Concentration | Viability & Functionality | Remarks |

|---|---|---|---|

| FBS (Reference) | 10% | Baseline for comparison | Traditional standard, raises ethical and safety concerns [31] |

| CryoStor CS10 | 10% | High viability and functionality comparable to FBS | Serum-free, effective for long-term (2-year) cryopreservation |

| NutriFreez D10 | 10% | High viability and functionality comparable to FBS | Serum-free, performs well in long-term storage |

| Bambanker D10 | 10% | Comparable viability, diverging T-cell functionality | Serum-free, may require functional validation for immune assays |

| Media with <7.5% DMSO | <7.5% | Significant viability loss | Eliminated from long-term study after initial assessment |

The data demonstrate that serum-free media containing 10% DMSO (CryoStor CS10 and NutriFreez D10) can effectively preserve cell viability and functionality over a two-year period, matching the performance of traditional FBS-supplemented media [30]. This is a significant finding for biobanking and clinical trials requiring long-term sample storage.

Detailed Protocols

Protocol 1: Preparation and Use of Standard Freezing Media

This protocol outlines the procedure for creating and using traditional serum-containing freezing media [32].

Reagents and Materials

- Log-phase cells at >80% confluency and >90% viability [13] [32]

- Complete growth medium (basal medium + serum)

- Fetal Bovine Serum (FBS)

- Cryoprotectant: Dimethyl Sulfoxide (DMSO, cell culture grade) or Glycerol

- Balanced salt solution (e.g., DPBS) without Ca2+/Mg2+ [32]

- Dissociation reagent (e.g., trypsin) for adherent cells [32]

- Sterile conical tubes (15 mL or 50 mL)

- Sterile cryogenic vials

Freezing Medium Formulation

A common standard formulation consists of:

- 50-90% Complete Growth Medium

- 10-50% FBS

- 10% DMSO [32]

Note: DMSO should be added last, and the complete freezing medium should be chilled (2°-8°C) before use to minimize DMSO toxicity [32].

Step-by-Step Procedure

- Harvest Cells: For adherent cells, wash with DPBS and detach using an appropriate dissociation reagent. Gently resuspend the detached cells in complete growth medium [32].

- Count and Centrifuge: Determine total cell count and viability. Centrifuge the cell suspension at approximately 100–400 × g for 5-10 minutes. Aspirate and discard the supernatant carefully [32].

- Resuspend in Freezing Medium: Resuspend the cell pellet in the pre-chilled standard freezing medium to achieve a final concentration typically between 1x10^6 to 1x10^7 cells/mL [13] [32]. Gently mix to ensure a homogeneous cell suspension.

- Aliquot: Dispense the cell suspension into sterile cryogenic vials, typically 1 mL per vial. Mix the suspension gently but frequently during aliquoting to ensure consistent cell density across vials [32].

- Freeze: Place the cryovials in an isopropanol freezing container (e.g., "Mr. Frosty") or an isopropanol-free container (e.g., Corning CoolCell) and immediately transfer to a -80°C freezer for 18-24 hours (or overnight) to achieve a cooling rate of approximately -1°C/minute [13] [32].

- Long-Term Storage: After 24 hours, promptly transfer the cryovials to a liquid nitrogen storage tank for long-term preservation in the vapor phase (below -135°C) [13] [32].

Protocol 2: Application of Commercial Serum-Free Freezing Media

This protocol describes the use of ready-to-use commercial serum-free media, which are increasingly critical for standardized and clinical-grade workflows [13].

Reagents and Materials

- Log-phase cells at >80% confluency and >90% viability [13]

- Commercial serum-free freezing medium (e.g., CryoStor CS10, NutriFreez D10, mFreSR) [30] [13]

- Balanced salt solution (e.g., DPBS)

- Dissociation reagent for adherent cells

- Sterile conical tubes

- Sterile cryogenic vials

Freezing Medium Selection

Select a medium optimized for your specific cell type:

- General Cell Types (PBMCs, etc.): CryoStor CS10 [30] [13]

- Human ES/iPS Cells: mFreSR [13]

- Mesenchymal Stromal Cells (MSCs): MesenCult-ACF Freezing Medium [13]

Step-by-Step Procedure

- Harvest Cells: Harvest cells as described in Protocol 1, Step 1.

- Count and Centrifuge: Determine total cell count and viability. Centrifuge the cell suspension and aspirate the supernatant completely.

- Resuspend in Commercial Medium: Resuspend the cell pellet directly in the pre-chilled, ready-to-use commercial serum-free medium at the manufacturer's recommended cell density (e.g., 1-2x10^6 cells/mL for iPSCs [34]). The medium already contains the optimized cryoprotectant (typically 10% DMSO) and other protective agents [13].

- Aliquot: Dispense the cell suspension into cryogenic vials, mixing gently to maintain homogeneity.

- Freeze: Use a controlled-rate freezing apparatus or a validated freezing container (e.g., CoolCell) placed at -80°C to ensure a consistent cooling rate of -1°C/minute [13].

- Long-Term Storage: Transfer vials to liquid nitrogen for long-term storage within 24 hours.

Workflow and Decision Pathway

The following diagram illustrates the key decision-making process and workflow for selecting and using an appropriate freezing media protocol.

The Scientist's Toolkit: Essential Reagents and Materials

Table 3: Key Research Reagent Solutions for Cryopreservation

| Item | Function/Application | Examples & Notes |

|---|---|---|

| Cryoprotective Agents (CPAs) | Penetrate cell membrane, reduce ice crystal formation | DMSO (10%): Gold standard, intracellular CPA [34] [35]. Glycerol: Alternative intracellular CPA [32]. Handle DMSO with care. |

| Controlled-Rate Freezing Containers | Ensure optimal cooling rate (~-1°C/min) for cell survival | Isopropanol-containing: Nalgene Mr. Frosty [32]. Isopropanol-free: Corning CoolCell [13] [34]. Avoid non-validated homemade devices [34]. |

| Commercial Serum-Free Media | Ready-to-use, defined formulation for specific cell types | CryoStor CS10: General purpose & stem cells [13]. mFreSR: For human ES/iPS cells [13]. NutriFreez D10: Effective for PBMCs [30]. |

| Liquid Nitrogen Storage System | Long-term storage at <-135°C to halt metabolic activity | Store cryovials in the vapor phase of liquid nitrogen to prevent explosion risks associated with liquid phase storage [32] [34]. |

| Cell Detachment Reagents | Gently detach adherent cells for harvesting before freezing | Trypsin or TrypLE Express [32]. Minimize exposure time to maintain high viability. |

| Viability/Cell Counting Assays | Quantify cell count and viability pre-freeze and post-thaw | Trypan Blue exclusion with hemocytometer or automated cell counters (e.g., Countess) [32]. |

The choice between standard formulations and commercial serum-free alternatives for freezing media is a strategic decision that impacts experimental reproducibility, cell viability, and regulatory compliance. While standard FBS-DMSO formulations remain a cost-effective option for basic research, commercial serum-free media provide a robust, defined, and consistent solution ideal for critical applications, long-term biobanking, and clinical development.

Evidence confirms that leading serum-free media can match or exceed the performance of traditional media in preserving cell viability and functionality over extended periods [30]. Adhering to optimized protocols—emphasizing healthy starting cells, controlled-rate freezing, and proper storage conditions—is essential for success, regardless of the media chosen. As the field advances, the trends toward cGMP manufacturing, specialized formulations, and reduced DMSO content will further solidify the role of commercial serum-free media in modern biomedical research and therapeutic development.

Controlled-rate freezing is a cornerstone technique in biomedical research and biopharmaceutical development, essential for the long-term preservation of cell lines, primary cells, and sensitive biological therapeutics. By precisely managing the cooling process, researchers can mitigate the damaging effects of ice crystal formation, maintain cellular viability, and ensure the genetic and functional integrity of biological materials over indefinite storage periods. The standard cooling profile of -1°C per minute has emerged as a gold protocol for a wide variety of mammalian cells, representing a critical parameter that balances the osmotic stress and intracellular ice formation [1] [36]. This application note details the underlying principles, provides definitive protocols, and characterizes the necessary equipment to master this fundamental procedure, framing it within the broader context of cell freezing and thawing protocol research.

Principles and Mechanisms

The fundamental goal of controlled-rate freezing is to navigate the physical phase change of water from liquid to solid in a way that minimizes lethal damage to cellular structures.

The Physics of Cell Damage During Freezing

During uncontrolled freezing, two primary mechanisms cause cell death:

- Intracellular Ice Formation (IIF): If cooling occurs too rapidly, water within the cell does not have sufficient time to exit and forms destructive ice crystals that puncture organelles and the plasma membrane [1].

- Solution Effects (Solute Imbalance): If cooling is too slow, the prolonged exposure to a hypertonic extracellular environment causes excessive cellular dehydration and shrinkage, leading to osmotic stress and protein denaturation [1].

The -1°C/minute cooling rate is optimized to avoid both extremes. It allows enough time for water to osmotically exit the cell, thereby minimizing IIF, but is sufficiently rapid to limit the duration of exposure to damaging solute concentrations [36].

The Role of Cryoprotectants

Cryoprotectant agents (CPAs) like Dimethyl Sulfoxide (DMSO) or glycerol are integral to the process. They function by:

- Reducing the freezing point of the medium.

- Lowering the salt concentration in the residual unfrozen fraction, thus mitigating "solution effects" [1] [26].

- Amortizing the cell membrane and stabilizing proteins [13].

The following diagram illustrates the sequential protective mechanisms enabled by the controlled -1°C/minute rate and cryoprotectants.

Diagram 1: Protective cascade of controlled-rate freezing.

Successful cryopreservation depends on optimizing several interdependent parameters. The table below summarizes these key variables and their typical specifications for standard mammalian cell lines.

Table 1: Key Parameters for Controlled-Rate Freezing Protocols

| Parameter | Standard Specification | Rationale & Impact |

|---|---|---|

| Cooling Rate | -1°C / minute from room temperature to -40°C to -80°C [1] [36] | Balances water efflux (prevents IIF) against exposure time to hypertonic conditions (prevents solute damage) [36]. |

| Cell Viability (Pre-freeze) | >90% (Minimum >75%) [1] [26] | Ensures a healthy population is preserved; low viability compromises post-thaw recovery. |

| Cell Concentration | ~1 x 10^6 cells/mL [1] [13] | Optimal density for survival; too low can lead to poor recovery, too high can cause clumping. |

| Cryoprotectant | 5-10% DMSO or 10% Glycerol [1] [26] | DMSO is most common; Glycerol is alternative for sensitive lines. Cytotoxic at room temperature, requiring rapid handling. |

| Freezing Medium | 90% FBS* + 10% DMSO, or serum-free commercial media (e.g., CryoStor) [1] [26] [13] | *FBS provides extra protein and membrane stabilization. Defined, serum-free media are preferred for regulatory-compliant work. |

| Final Storage Temperature | < -135°C (typically in liquid nitrogen vapor phase) [36] [13] | Halts all metabolic activity. Storage at -80°C is suboptimal and leads to declining viability over weeks/months [1] [36]. |

Equipment and Methodology

Equipment for Achieving Controlled Cooling

Several technologies can achieve the -1°C/minute profile, each with distinct advantages.

Table 2: Comparison of Controlled-Rate Freezing Equipment

| Equipment Type | Mechanism | Advantages | Disadvantages |

|---|---|---|---|

| Programmable Controlled-Rate Freezer [36] | Uses a pre-programmed cooling profile, often with liquid nitrogen injection. | Highest precision and reproducibility; validatable processes; suitable for sensitive cells and scalable volumes [36]. | High equipment cost; not as accessible for all labs. |

| Passive Cooling Devices (e.g., CoolCell or "Mr. Frosty") [1] [26] | Uses an isopropanol chamber or other insulator to create a predictable cooling rate in a -80°C freezer. | Low-cost, simple, and reliable; requires no electricity; highly accessible [1]. | Limited capacity; cooling rate is fixed and dependent on freezer performance. |

| Liquid Nitrogen-Free Freezers [37] | Uses mechanical refrigeration and precise control systems. | Portable; safe for cleanrooms (no contamination risk from LN2); lower long-term costs [37]. | Limited maximum freezing rate (~-1°C/min); may not be suitable for all cell types [37]. |

Standardized Freezing Protocol for Mammalian Cells

The following step-by-step protocol is applicable to both adherent and suspension mammalian cell lines.

Pre-freeze Preparation:

- Cell Status: Culture cells to mid-log phase growth (>90% viability, >80% confluency for adherent cells) [26] [13].

- Freezing Medium: Prepare fresh, and pre-cool to 2-8°C. A common formulation is 90% FBS + 10% DMSO. Warm to 37°C before use is also recommended by some protocols [1].

- Aseptic Technique: Perform all steps under sterile conditions in a laminar flow hood [13].

Procedure:

- Harvest Cells: For adherent cells, wash with PBS and detach using a standard dissociation reagent like trypsin. For suspension cells, proceed directly [1] [26].

- Neutralize & Count: Resuspend cells in complete growth medium. Determine total cell count and viability using a hemocytometer or automated cell counter with Trypan Blue exclusion [1] [26].

- Pellet and Resuspend: Centrifuge the cell suspension at 300 x g for 5 minutes. Aspirate the supernatant completely. Gently loosen the cell pellet [1].

- Re-suspension in Freezing Medium: Resuspend the cell pellet in the pre-cooled freezing medium to a final concentration of ~1 x 10^6 cells/mL [1] [13]. Mix gently but thoroughly to ensure a homogeneous suspension.

- Aliquoting: Quickly aliquot 1 mL of the cell suspension into labeled, sterile cryovials. Keep vials on ice or in a cooler after aliquoting [1].

- Initiate Freezing: Immediately transfer the cryovials to a pre-equilibrated controlled-rate freezing device.

- Long-Term Storage: Within 24 hours, transfer the cryovials to long-term storage in the vapor phase of liquid nitrogen (< -135°C) [1] [36]. Avoid prolonged storage at -80°C.

Diagram 2: Experimental workflow for cell cryopreservation.

The Scientist's Toolkit: Essential Research Reagents and Materials

A successful cryopreservation workflow relies on specific, high-quality materials. The following table lists essential items and their functions.

Table 3: Essential Reagents and Materials for Controlled-Rate Freezing

| Item | Function & Application Notes |

|---|---|

| Cryoprotectant (DMSO/Glycerol) | Penetrating agent that reduces ice crystal formation. Use high-purity, cell culture-tested grade. Handle with care as DMSO facilitates cellular uptake of other molecules [26]. |