Comprehensive Cleaning Protocols for Biological Safety Cabinets: From Basic Procedures to Evidence-Based Validation

This article provides researchers, scientists, and drug development professionals with a complete guide to establishing and validating effective cleaning protocols for Biological Safety Cabinets (BSCs).

Comprehensive Cleaning Protocols for Biological Safety Cabinets: From Basic Procedures to Evidence-Based Validation

Abstract

This article provides researchers, scientists, and drug development professionals with a complete guide to establishing and validating effective cleaning protocols for Biological Safety Cabinets (BSCs). It covers foundational principles of BSC operation and contamination risks, detailed step-by-step cleaning and disinfection methodologies, troubleshooting for common issues, and a comparative analysis of disinfectant efficacy based on recent scientific studies. The content synthesizes manufacturer guidelines, institutional safety protocols, and peer-reviewed research to offer evidence-based strategies for preventing cross-contamination, ensuring personnel safety, and maintaining the integrity of sensitive cell-processing and microbiological work.

Understanding Biological Safety Cabinets: The Critical Role of Cleaning in Containment

The Function and Importance of BSCs in Laboratory Safety

Biological Safety Cabinets (BSCs) are engineered enclosures that provide a critical primary barrier between laboratory personnel and potentially hazardous biological agents. By utilizing High-Efficiency Particulate Air (HEPA) filters and controlled airflow patterns, they create a contained workspace essential for modern research, clinical diagnostics, and pharmaceutical development [1] [2]. Their function extends beyond personnel protection to also safeguarding the experimental sample integrity and the external environment from contamination [3] [4]. Within the specific context of research on cleaning protocols, the BSC itself becomes both the object of study and a vital tool, ensuring that decontamination methodologies are tested in a controlled and safe manner. This technical support center addresses the key operational, troubleshooting, and procedural questions researchers encounter while integrating BSCs into their experimental workflows.

Troubleshooting Guides

Q1: The airflow alarm on my BSC is activated. What steps should I take?

An activated airflow alarm indicates a potential compromise in cabinet containment, which requires immediate and careful action.

- Step 1: Cease all work immediately. Stop your experiment as soon as it is safe to do so. Do not ignore the alarm [5].

- Step 2: Check the alarm panel. Consult the BSC's interface for an error code or message that can specify the issue, such as low inflow velocity, high sash, or a system failure [5] [6].

- Step 3: Refer to the user manual. The manufacturer's manual will provide specific troubleshooting steps for the displayed error code.

- Step 4: Safely back out. If the alarm persists, slowly and carefully remove your arms and materials from the cabinet, ensuring not to disrupt the remaining airflow barrier further. Seal any biohazardous materials [7].

- Step 5: Report and quarantine. Report the issue to your lab manager or biosafety officer. The BSC should be taken out of service until a qualified technician can diagnose and repair the fault. Do not attempt to use the cabinet until it has been recertified [5].

Q2: I suspect my BSC's HEPA filters are clogged. What are the signs and solutions?

HEPA filters have a finite lifespan and can become loaded with particles over time, reducing the cabinet's performance and safety.

Signs of a Clogged Filter:

- A noticeable reduction in airflow velocity, often indicated by the cabinet's gauges or alarms [5].

- Increased noise from the cabinet's blower as it works harder to maintain airflow [5].

- Inability to maintain proper face velocity during annual certification [7].

- Visible damage or an unusual odor, though these are less common [5].

Solutions:

- Cease use and contact a qualified technician. Filter replacement is not a user-level task. The BSC must be decontaminated, typically with formaldehyde gas, before any filter work is performed [7] [5].

- Adhere to a preventative maintenance schedule. Filters should be tested during annual certification, and replaced as needed based on performance metrics, not a fixed timeline [7] [6].

Q3: My experiments are consistently showing contamination. Could my aseptic technique or BSC be the cause?

Consistent contamination points to a breach in sterile procedure, which could involve both user technique and cabinet status.

Investigate Your Aseptic Technique:

- Movement: Ensure you are using slow, deliberate movements to avoid creating turbulent air currents that can pull contaminated air into the work zone [7] [8] [4].

- Organization: Keep "clean" and "dirty" (contaminated) items clearly separated within the cabinet. Do not pass contaminated materials over clean items [7].

- Placement: Perform all work at least 4 inches inside the cabinet window and avoid blocking the front and rear grilles [7].

- Preparation: Place all necessary items inside the cabinet before starting work and minimize the frequency of moving arms in and out [7] [4].

Investigate Your BSC's Status and Placement:

- Certification: Confirm the BSC has a current certification (within the last year) for HEPA filter integrity and airflow velocity [7] [9].

- Location: The BSC should be placed away from doors, high-traffic areas, and air conditioning vents, as these can create disruptive drafts [7] [9].

- Purge Time: Allow the BSC to run for at least 5-15 minutes with no activity before beginning work to purge airborne contaminants from the work area [7] [9] [4].

Frequently Asked Questions (FAQs)

Q1: What is the proper daily cleaning protocol for a BSC within a research context?

A rigorous daily cleaning protocol is fundamental for preventing contamination and ensuring reproducible results in cleaning research.

- Pre-cleaning: Turn on the cabinet and allow it to run for a minimum of 5 minutes to purge airborne particles [9] [4].

- Surface Disinfection: Thoroughly wipe all interior surfaces—work surface, side walls, and back wall—with a disinfectant such as 70% ethanol or a suitable alternative. Use a clean cloth or paper towel, moving from the cleanest area (typically the top) towards the drain [7] [9].

- Post-cleaning: After the disinfection contact time, a rinse with sterile water may be necessary to remove corrosive disinfectant residues. Wipe the surfaces dry [7] [4].

- Final Purge: After cleaning, let the cabinet run for 2-3 more minutes before shutting it down to remove any dislodged particles [7].

Q2: How often should a BSC be certified, and what does the process involve?

Certification is not optional; it is a mandatory requirement for safety and data integrity.

- Frequency: BSCs must be certified at the time of installation, after being moved, after any internal servicing or filter replacement, and at least annually thereafter [7] [10].

- Process: Performed by a qualified technician, certification involves several key tests [7] [10]:

- HEPA Filter Integrity Test: Verifies there are no leaks in the HEPA filter.

- Airflow Velocity Tests: Measures inflow (air drawn into the front) and downflow (air flowing down onto the work surface) velocities to ensure they meet specifications.

- Draft Inflow Visualization (Smoke Test): Visually confirms that air from the room flows into the cabinet front without escaping.

- Particle Count Test: Determines the air quality and cleanliness level inside the cabinet.

Q3: Is it safe to use a Bunsen burner inside a Class II BSC?

No. The use of an open flame, such as a Bunsen burner, is strongly discouraged within a Class II BSC [7] [9]. The heat from the flame creates convective currents that disrupt the critical laminar airflow, potentially compromising both personnel and product protection. It also poses a fire hazard. Alternatives like flameless electric incinerators or disposable sterile loops should be used for sterilization within the cabinet [7].

Q4: What is the role of UV lights in BSC decontamination?

UV lights can serve as an optional supplementary decontamination method but must never be relied upon as the primary means of disinfection [7] [8].

- Function: UV irradiation can help maintain surface decontamination between uses and can reach difficult-to-access areas [8].

- Limitations and Safety:

- Effectiveness requires direct, uninterrupted line-of-sight and is reduced by dust or shadows [7].

- UV lamps must be cleaned weekly with 70% ethanol and tested periodically to ensure sufficient energy output [7].

- The UV light must never be on while the room is occupied, as exposure can cause severe skin burns and eye damage [7] [4].

- The cabinet's sash must be closed when the UV light is on to contain hazardous UV illumination [7].

Experimental Protocols for Cleaning Research

For researchers developing and validating new cleaning protocols, the following methodologies provide a standardized framework for evaluating disinfectant efficacy within a BSC environment.

Protocol 1: Quantitative Surface Decontamination Efficacy

This protocol tests the log reduction of a microbial population on BSC surfaces after disinfectant application.

- Objective: To quantitatively determine the efficacy of a disinfectant against specific bacterial or fungal spores on stainless-steel coupons simulating a BSC work surface.

- Materials:

- Sterile stainless-steel coupons (e.g., 2cm x 2cm)

- Test organism suspension (e.g., Bacillus subtilis spores, ~10^6 CFU/mL)

- Disinfectant solutions under test (e.g., 70% Ethanol, fresh bleach solution)

- Neutralizing broth (to halt disinfectant action)

- Sterile swabs or contact plates

- Incubator and materials for colony counting

- Methodology:

- Inoculation: Apply a known volume (e.g., 10µL) of the test organism suspension onto the center of each coupon and allow to dry completely inside the BSC.

- Application: Apply the test disinfectant to the inoculated surface for a predetermined contact time (e.g., 1, 5, 10 minutes), ensuring full coverage.

- Neutralization: After contact time, immediately neutralize the disinfectant by adding neutralizing broth or using a pre-moistened neutralizing swab.

- Sampling and Enumeration: Vigorously swab the entire surface of the coupon and transfer the swab to a known volume of neutralizer. Serially dilute and plate for viable colony count.

- Control: Include a positive control (inoculated, not disinfected) and a negative control (non-inoculated) to validate the method.

- Data Analysis:

Calculate the log reduction using the formula:

Log Reduction = log10(Control CFU) - log10(Test CFU after disinfection)A effective disinfectant should demonstrate a ≥3-log (99.9%) reduction under the tested conditions.

Protocol 2: Aerosol Containment Validation during Cleaning Procedures

This experiment assesses whether aerosol-generating cleaning activities compromise the BSC's containment.

- Objective: To verify that simulated cleaning actions (e.g., spraying, vigorous wiping) do not cause the release of aerosolized particles from within the operating BSC.

- Materials:

- Aerosol generator (nebulizer) and non-pathogenic tracer organism (e.g., Bacillus atrophaeus)

- Microbial air samplers (e.g., slit-to-agar samplers or gelatin filters)

- Culture media and incubator

- Methodology:

- Setup: Place an air sampler immediately outside the BSC's front opening and another inside the laboratory room.

- Aerosol Generation: Inside the operating BSC, use the nebulizer to generate an aerosol of the tracer organism for a fixed duration.

- Simulated Cleaning: Simultaneously, perform the cleaning action being tested (e.g., spray disinfectant onto a cloth inside the BSC, then wipe surfaces).

- Air Sampling: Run the external and room air samplers throughout the aerosol generation and cleaning procedure.

- Analysis: Incubate the air sampler collection media and count the resulting colonies.

- Data Analysis: Compare the colony counts from the samplers placed outside the BSC to those from a control sampler placed inside the BSC during the test. Effective containment is demonstrated by a significant reduction (ideally, zero growth) in the external samplers, confirming that aerosols were not released.

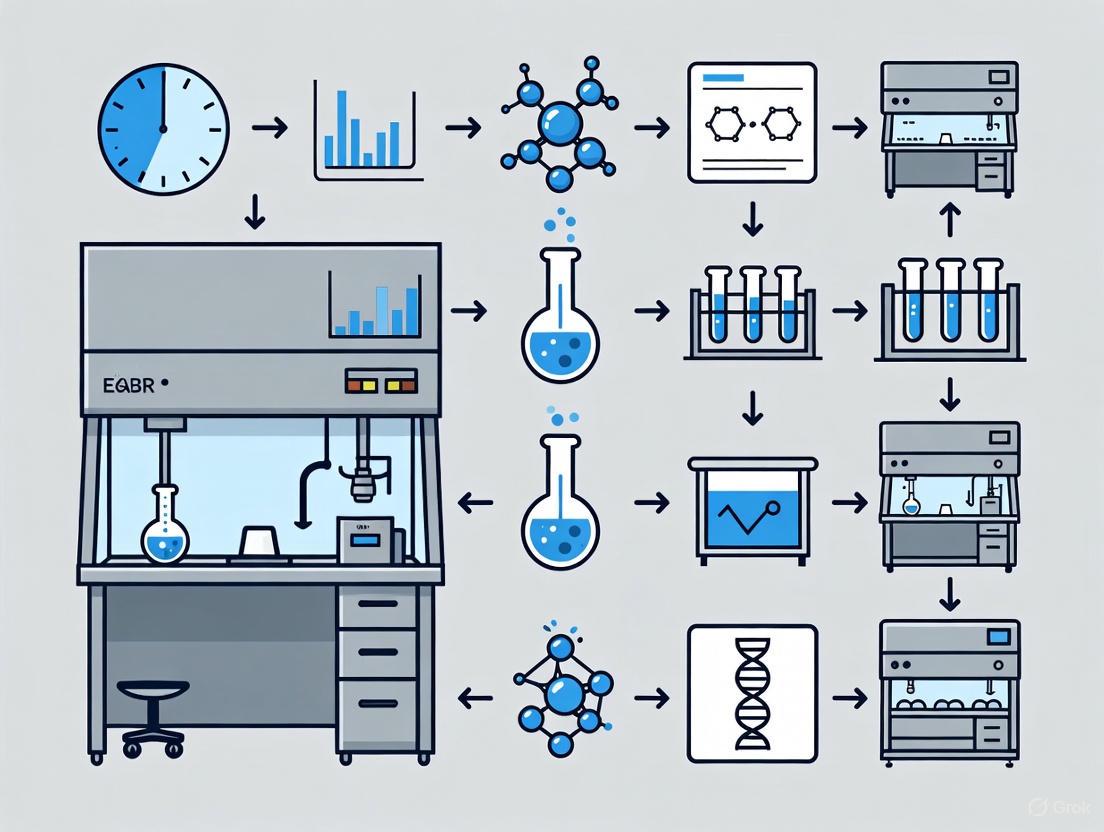

The logical workflow for designing and executing these cleaning validation experiments is outlined below.

Research Reagent Solutions for BSC Cleaning Studies

The following table details key materials and reagents used in experimental protocols for evaluating BSC decontamination.

| Reagent/Material | Function in Experiment | Key Considerations |

|---|---|---|

| 70% Ethanol | A common disinfectant for routine surface decontamination; effective against many bacteria and fungi. | Evaporates quickly, no residue; not sporicidal; can damage some plastics over time [8] [4]. |

| Sodium Hypochlorite (Bleach) | A strong oxidizing agent used for broad-spectrum disinfection, including sporicidal activity. | Corrosive to stainless steel; must be rinsed with sterile water or ethanol after use; concentration and contact time are critical [7] [9]. |

| Stainless-Steel Coupons | Inert, non-porous surfaces used to simulate the BSC work surface for standardized efficacy testing. | Easy to clean, autoclave, and reusable; representative of the actual cabinet material [10]. |

| Neutralizing Broth | Used to halt the antimicrobial action of disinfectants at the end of the contact time for accurate microbial counting. | Essential for obtaining valid quantitative data; must be validated for the specific disinfectant used. |

| Bacillus subtilis spores | A common biological indicator for validating sporicidal activity due to their high resistance to disinfectants. | Provides a rigorous challenge for testing the efficacy of a decontamination protocol [4]. |

| HEPA/ULPA Filters | The primary containment engineering control that removes airborne particles and microorganisms. | Must be integrity tested annually; requires professional decontamination before replacement [7] [6]. |

FAQs: Understanding and Mitigating Contamination Risks

1. What are the most common sources of contamination in a Biological Safety Cabinet (BSC)?

The most common sources come from both the laboratory environment and researcher practices:

- Airborne Microorganisms: Non-sterile ambient laboratory air and personnel are key sources. Humans constantly shed skin cells covered in bacteria [11].

- Improperly Disinfected Materials: Any items brought into the BSC, including equipment and containers, can introduce contaminants if not properly disinfected [11].

- Poor Work Practices: Rapid movements, working with the BSC sash at the wrong height, and cluttering the work surface can disrupt airflow and compromise the protective barrier [12] [11].

- Inadequate Cleaning: Failure to decontaminate all interior surfaces (sides, back, and underside of the view screen) before and after work leads to cross-contamination [12].

2. How does a BSC's airflow protect my samples and me, and what can compromise it?

A Class II BSC, the most common type, provides protection through a balanced system of HEPA-filtered air [13] [11]:

- Inflow: Room air is drawn in through the front grille, creating a barrier that protects the researcher from aerosols generated inside the cabinet.

- Downflow: HEPA-filtered air is blown vertically down onto the work surface, protecting samples from airborne contaminants in the room.

- Exhaust: Contaminated air from the work area is HEPA-filtered before being exhausted back into the room or to the outside.

This balance is compromised by: blocking the front or rear grilles with materials [11], using the BSC for storage [11], placing the cabinet in a high-traffic area where people walking by create cross-drafts [12], and raising the sash above its designated operating height [12].

3. Are UV lights an effective method for decontaminating a BSC?

No, ultraviolet (UV) lights are not a reliable primary method for decontamination. Experts advise that good chemical disinfection is much more effective [13] [12]. UV light has poor penetrating power and only works on surfaces directly in its line of sight, not on contaminants underneath materials or in shadows. Dust and other materials can condense on the bulb, reducing its effectiveness, and its germicidal function diminishes over time [12]. Therefore, UV is not a substitute for aseptic technique and thorough chemical disinfection.

4. What is the proper sequence for cleaning and decontaminating a BSC?

A systematic protocol is essential to prevent spreading contaminants [14]:

- Prepare: Before starting, gather all necessary cleaning supplies. Operators should wipe their gloves with 70% Isopropyl Alcohol (IPA) to avoid introducing contaminants [14].

- Apply Disinfectant: Use an appropriate disinfectant (e.g., a 1:10 fresh bleach solution). To avoid aerosolizing contaminants, do not spray corrosive disinfectants liberally; instead, use a squirt bottle or apply the disinfectant to a cloth [12].

- Wipe Systematically: Clean all interior surfaces in a specific order: top to bottom and from the cleanest to the dirtiest areas (typically back to front, and from one side to the other) [14]. This workflow ensures that any dislodged contaminants are moved toward the front grille and away from sterile areas.

- Rinse (if needed): If using a corrosive disinfectant like bleach, follow with a rinse of 70% ethanol or sterile water to prevent damage to the BSC's stainless steel surfaces [12].

- Final Steps: Remove waste and gloves properly, and wash hands upon completion [15].

Troubleshooting Guides

Problem: Consistent Sample Contamination

Potential Causes and Solutions:

| Potential Cause | Diagnostic Steps | Corrective Action |

|---|---|---|

| Compromised HEPA Filters | Check certification sticker; filters require integrity testing annually [13]. | Contact a certified professional to test and replace filters if needed [13]. |

| Improper Aseptic Technique | Review workflow: are you moving from "clean to dirty" and using slow, deliberate motions? [11] | Re-train on aseptic technique. Ensure all items are disinfected before entering BSC [11]. |

| Blocked Airflow | Inspect front and rear grilles for obstructions like papers or supplies [11]. | Remove all items blocking the grilles. Never use the BSC for storage [11]. |

| Inadequate Surface Decontamination | Review cleaning SOP. Are all surfaces, including hard-to-reach areas, being wiped? [12] | Use a tool like a Swiffer-style mop handle to properly clean the back and sides of the BSC [12]. |

Problem: A Large Spill of Biohazardous Material Occurs Inside the BSC

Immediate Action Protocol:

- Contain: Immediately cover the spill with absorbent towels or pads soaked in an appropriate disinfectant. Let it sit for the required contact time (e.g., 15-20 minutes for bleach) to ensure decontamination [11].

- Clean: While wearing gloves and other appropriate PPE, carefully wipe up the spill, working from the edges toward the center to avoid spreading. Place all cleanup materials in a biohazard bag [11].

- Decontaminate: Thoroughly clean the entire spill area and any other potentially contaminated surfaces with disinfectant. If the spill reached the drain valve or under the work surface, these areas must also be decontaminated [12].

- Dispose: Seal the biohazard bag inside the BSC. Never place waste from a spill outside the cabinet during cleanup [11].

Problem: The BSC Alarm Sounds or Airflow Feels Abnormal

Steps to Take:

- Immediate Action: Stop all work inside the cabinet. Inform your lab manager and contact your institutional biosafety officer or maintenance department [13].

- Do Not Use: The BSC must not be used until a qualified professional can test and re-certify it [13]. Using an uncertified or malfunctioning BSC provides a false sense of security and poses a significant safety risk.

Experimental Data on Airborne Contamination

A study measured Total Airborne Bacteria (TAB) concentrations in front of 11 BSCs at universities and hospitals to assess if TAB is a good indicator of BSC performance [16]. The results showed no significant difference in TAB concentrations between accredited (passed performance tests) and non-accredited BSCs, indicating that TAB concentration outside the BSC is not a reliable index of its containment performance [16].

Table: Total Airborne Bacteria (TAB) Concentrations in Laboratory Settings [16]

| Sampling Condition | TAB Concentration Range (CFU/m³) | Mean TAB Concentration (CFU/m³) |

|---|---|---|

| BSC Off, Shield Open | 21 to 702 | 164 |

| BSC Off, Shield Closed | 28 to 543 | 182 |

| BSC On and Operating | 57 to 205 | Not Reported |

| Background (Room Center) | 14 to 386 | 146 |

Research Reagent Solutions for Decontamination

Table: Essential Materials for BSC Decontamination and Cleaning

| Item | Function | Key Consideration |

|---|---|---|

| 70% Isopropyl Alcohol (IPA) | Effective disinfectant for routine surface decontamination; evaporates quickly without residue [14]. | Used to wipe gloves before starting work and for general surface disinfection [14]. |

| Sodium Hypochlorite (Bleach) | Broad-spectrum disinfectant at a 1:10 dilution; effective against viruses, bacteria, and fungi [12]. | Corrosive; surfaces must be rinsed with 70% ethanol or sterile water after use to prevent damage [12]. |

| Ethanol (70%) | Effective disinfectant; less corrosive than bleach [12]. | Often used as a rinse after bleach disinfection or as a primary disinfectant for certain applications [12]. |

| Wipes (Lint-Free) | For applying disinfectants; lint-free material prevents introducing new particles into the critical work zone [11]. | |

| Swiffer-Style Mop Handle | Allows for safe and effective cleaning of hard-to-reach areas at the back and sides of the BSC without the user having to lean in [12]. | Important for maintaining a consistent cleaning protocol for all interior surfaces [12]. |

Workflow for Contamination Control

The following diagram illustrates the critical "clean-to-dirty" workflow that must be followed when setting up and working within a BSC to maintain aseptic conditions and prevent cross-contamination.

Within life sciences research, Biological Safety Cabinets (BSCs) serve as a critical engineering control, providing a protected environment for working with biohazardous materials. The integrity of this containment is fundamentally dependent on the correct cleaning and maintenance of its key physical components. A single compromised surface or a clogged filter can break the chain of containment, jeopardizing both experimental validity and personnel safety. This article examines the cleaning protocols for five essential components—the work surface, walls, sash, front grille, and HEPA filters—framing them not as routine chores but as foundational practices for rigorous and reproducible science.

â–ŽTroubleshooting Guides & FAQs

Work Surface and Interior Walls

Q: What is the proper technique for disinfecting the work surface and walls, and why does the order of wiping matter?

A systematic wiping technique is crucial to prevent the spread of contaminants from dirtier areas to cleaner ones.

- Protocol: Disinfect all interior surfaces, including the work surface, side walls, back wall, and the interior of the glass sash, before and after each use [17] [9]. The established methodology is to wipe in a consistent order: top to bottom and from the cleanest areas to the dirtiest [18]. This prevents contaminants from higher or dirtier surfaces from being transferred to already-cleaned zones.

- Troubleshooting: If you notice persistent contamination in cell cultures after working in the BSC, it may be due to improper disinfection. Ensure the disinfectant remains in contact with the surface for the full manufacturer-recommended contact time to be effective [17]. Avoid spraying disinfectants directly inside the BSC, as aerosolized chemicals can corrode sensitive components like HEPA filters; instead, apply the disinfectant to a wipe or use pre-moistened wipes [17].

Q: How do I prevent corrosion on the stainless steel work surface?

Certain disinfectants, while effective, can damage the cabinet over time.

- Protocol: A common and effective method is a two-step process: wipe down the interior with a disinfectant like a 1:10 fresh bleach solution, then follow with a rinse wipe using 70% ethanol or sterile water to remove corrosive residues [7] [6] [19].

- Troubleshooting: If you observe discoloration or pitting on the stainless steel, it is likely caused by the prolonged presence of corrosive disinfectants like bleach or iodine. Consistent use of a second wiping with ethanol or water is required to prevent this damage [7] [6].

Sash and Front Grille

Q: Why is it critical to keep the front grille unobstructed?

The front grille is the intake for the cabinet's airflow, which creates the vital air barrier protecting the user.

- Protocol: Never place supplies, notes, or any other items on or over the front intake grille or the rear exhaust grille [7] [17]. Maintain a clear pathway for air to flow into the grille unimpeded.

- Troubleshooting: A disrupted air curtain can allow contaminants to escape. If your BSC alarm triggers for low airflow, or if you see smoke tests during certification failing to be contained, immediately check for and remove any blockages at the front grille [20].

Q: What are the key points for cleaning the sash and the area around the front grille?

These areas require careful attention to maintain a sealed and clean environment.

- Protocol: The interior of the glass sash should be included in the standard wiping procedure [17]. When cleaning the basin or underside of the work surface near the grille, use heavy, disinfectant-soaked wipes or towels rather than lightweight ones. This prevents them from being sucked into the cabinet's riser, which would necessitate a major decontamination [7].

- Troubleshooting: If lightweight wipes are drawn into the riser, the BSC will require formal decontamination with formaldehyde gas and recertification before it can be used again, a costly and time-consuming process [7].

HEPA Filters

Q: How does routine cleaning impact the longevity and function of the HEPA filters?

HEPA filters are the final barrier preventing contaminated air from escaping. Proper cleaning protects them from damage.

- Protocol: Avoid using corrosive chemicals and never spray aerosolized disinfectants inside the BSC, as these can degrade the filter media and its seals [7] [17]. Decontaminate the entire cabinet before any internal filter servicing to protect the technician [7].

- Troubleshooting: HEPA filters cannot be cleaned and must be replaced when they become clogged or damaged. If the BSC's airflow monitor indicates a problem, or if certification fails the integrity test, the filters likely need replacement. This must be performed by a qualified technician after cabinet decontamination [7] [21].

Q: What is the certification schedule for HEPA filters?

Regular certification is non-negotiable for safety.

- Protocol: BSCs must be tested and certified upon installation, after being moved, after any filter service, and at least annually thereafter [7] [9] [21]. This ensures airflow velocity, integrity, and containment are all within specifications.

- Troubleshooting: Operating a BSC without a current certification is a significant safety risk. Laboratory managers must arrange for annual certification through a qualified vendor [7] [21].

â–ŽExperimental Data on Cleaning Efficacy

The following table summarizes quantitative data from a controlled study that evaluated the effectiveness of different cleaning methods against specific contaminants in a BSC environment [22].

Table 1: Efficacy of BSC Cleaning Methods Against Various Contaminants

| Cleaning Method | Mycoplasma orale | Feline Calicivirus (FCV) | Endotoxins (E. coli) | Notes / Key Findings |

|---|---|---|---|---|

| UV Irradiation (200 mJ/cm²) | Inhibited growth | Eliminated (Below detection limit) | No significant reduction | Ineffective on endotoxins; direct exposure required for microbes. |

| Wiping with Benzalkonium Chloride (BKC) | Inhibited growth | Eliminated (Below detection limit) | Significantly reduced | Showed broad efficacy across all tested contaminant types. |

| Wiping with 70% Ethanol (ETH) | Growth detected | Not specified in results | No significant reduction | Ineffective against mycoplasma and endotoxins in this study. |

| Wiping with Distilled Water (DW) | Not specified | Eliminated (Below detection limit) | Significantly reduced | Effective for virus and endotoxin removal, but not antimicrobial. |

Source: Adapted from ScienceDirect, 2024 [22]

â–ŽBSC Surface Cleaning and Contaminant Removal Workflow

The diagram below outlines the logical decision-making process for selecting a cleaning method based on the target contaminant, derived from experimental evidence [22].

â–ŽThe Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents for BSC Cleaning and Decontamination

| Reagent / Material | Primary Function | Key Considerations |

|---|---|---|

| 70% Ethanol (ETH) | Rapid evaporation and broad-spectrum disinfection for routine surface cleaning. | Ineffective against mycoplasma and endotoxins per some studies; requires corrosion follow-up if used after bleach [22] [19]. |

| Benzalkonium Chloride (BKC) | Broad-efficacy disinfectant. | Shown in studies to be effective against mycoplasma, viruses, and to reduce endotoxins [22]. |

| Sodium Hypochlorite (Bleach) | Strong oxidation for potent disinfection, often used at 1:10 dilution. | Corrosive to stainless steel; must be followed by a rinse wipe with ethanol or sterile water [7] [6]. |

| Distilled Water (DW) | Rinsing agent to remove disinfectant residue and prevent corrosion. | Not a disinfectant on its own, but effective for physical removal of some contaminants like endotoxins [22]. |

| HEPA Filter | Final barrier for particulate containment; cannot be cleaned. | Requires annual certification and replacement by a qualified technician after formal decontamination [7] [21]. |

| NCT-505 | ALDH1A1 Inhibitor|1-(6-Fluoro-3-(4-(methylsulfonyl)piperazine-1-carbonyl)quinolin-4-yl)-4-phenylpiperidine-4-carbonitrile | Potent, selective ALDH1A1 inhibitor for cancer research. This product, 1-(6-Fluoro-3-(4-(methylsulfonyl)piperazine-1-carbonyl)quinolin-4-yl)-4-phenylpiperidine-4-carbonitrile, is For Research Use Only. Not for human or veterinary diagnostic or therapeutic use. |

| CHMFL-PI4K-127 | CHMFL-PI4K-127, MF:C18H15ClN4O3S, MW:402.9 g/mol | Chemical Reagent |

A guide to ensuring your biological safety cabinet remains a safe and compliant primary barrier.

Biological safety cabinets (BSCs) are fundamental engineering controls in laboratories working with biohazardous materials. Their primary function is to provide three-way protection: for the personnel, the product, and the environment [17] [23]. Maintaining this protection is not just a matter of best practice—it is a requirement enforced by a robust framework of standards and regulations. This technical support center outlines the mandatory requirements and procedures to keep your BSC safe and compliant.

FAQs: Decontamination & Certification

Q1: What is the difference between daily cleaning, decontamination, and certification?

These are three distinct levels of maintenance, each with a specific purpose:

- Daily Cleaning: A routine surface disinfecting process performed by the user before and after each work session to remove general contaminants and maintain a sterile work area. It typically involves wiping surfaces with an appropriate disinfectant like 70% ethanol or a fresh 1:10 bleach solution followed by a rinse to prevent corrosion [7] [17] [24].

- Decontamination: A deeper process that eliminates viable biological agents. This can be a surface-level "deep cleaning" or a full gas decontamination that fumigates the entire interior, including plenums and filters. Gas decontamination uses chemical sterilants like chlorine dioxide, hydrogen peroxide vapor, or formaldehyde and must be performed by qualified professionals [25].

- Certification: A rigorous performance verification conducted by an accredited professional to ensure the BSC meets all manufacturer and standard (e.g., NSF/ANSI 49) operational specifications. This includes testing airflow velocities, HEPA filter integrity, and containment [26] [23].

Q2: When is gas decontamination of a BSC mandatory?

A risk assessment or specific regulations dictate the need for gas decontamination. According to industry standards, it is required in the following situations [25]:

- Before changing HEPA filters.

- Before any maintenance, repair, or replacement of internal BSC components.

- Before the cabinet is relocated or moved.

- Before final decommissioning, disposal, or surplus of the cabinet.

- After significant spills if surface decontamination is considered insufficient.

- Before field certification of cabinets used in BSL-3 (recommended) and BSL-4 (required) facilities.

Q3: What are the key regulatory triggers for BSC certification?

Certification is not a one-time event. The following table summarizes the mandatory triggers as outlined by multiple safety sources [7] [24] [26].

| Trigger | Regulatory/Safety Basis |

|---|---|

| Initial Installation | Ensures correct assembly and calibration before first use [26] [23]. |

| Annually | Required by CDC/NIH BMBL, NSF/ANSI 49, and other guidelines to verify ongoing performance [7] [23]. |

| After Relocation | Any movement can affect airflow balance and cabinet integrity [24] [26]. |

| After Filter Changes/Servicing | Verifies that the cabinet is safe and operational post-repair [7] [26]. |

| Following Contamination Incidents | Confirms the cabinet is safe to resume use after a significant spill [26]. |

Q4: Can I use a Bunsen burner or ultraviolet (UV) light in my BSC?

- Bunsen Burners: The use of open flames is strongly discouraged and is prohibited in many institutions [24] [23]. The flame creates turbulence that disrupts the protective air curtain, compromises containment, and the heat can damage HEPA filters [7] [24]. Alternatives include micro-burners with pilot lights, disposable loops, or small electric incinerators [7] [24].

- UV Lights: UV lamps are not recommended nor required by the CDC and NIH if proper aseptic technique is followed [7] [23]. Their effectiveness is limited by dust, lamp age, and humidity. They also pose a safety hazard to skin and eyes and should never be on while the room is occupied [7].

Troubleshooting Common BSC Issues

Problem: The BSC fails certification due to low inflow or downflow velocity.

- Possible Cause 1: Blocked front intake grille or rear exhaust grill. Even a single piece of paper can disrupt airflow [23].

- Solution: Ensure nothing is placed over the grilles. Organize supplies to keep them clear [17].

- Possible Cause 2: Overloading the cabinet with equipment or supplies.

- Possible Cause 3: Disruptive room air currents.

- Possible Cause 4: Failure of the blower motor or a clogged HEPA filter.

Problem: Contamination is suspected in cell cultures processed within the BSC.

- Possible Cause 1: Improper aseptic technique or workflow.

- Possible Cause 2: Inadequate surface decontamination.

- Possible Cause 3: Contaminated stored supplies.

- Solution: Do not use the BSC for storage. All extra supplies should be kept outside the cabinet [7].

The Scientist's Toolkit: Essential Reagents & Materials

The table below lists key materials required for the proper daily maintenance and decontamination of a biological safety cabinet.

| Item | Function & Application |

|---|---|

| 70% Ethanol or Isopropyl Alcohol (IPA) | Common disinfectant and rinse agent. Effective for general surface decontamination and for removing corrosive residues from bleach [7] [17] [27]. |

| Sodium Hypochlorite (Bleach) | A strong oxidizing agent used as a disinfectant, typically diluted 1:10. Effective against a broad spectrum of microorganisms. Must be rinsed with ethanol or sterile water after use to prevent corrosion of stainless steel surfaces [7] [24]. |

| Sterile Water | Used as a rinse after applying corrosive disinfectants like bleach to remove residues that could damage the cabinet [7] [9]. |

| Wipes (Heavy-weight, Lint-free) | For applying disinfectants. Heavy-weight wipes are recommended to prevent them from being drawn into the cabinet's internal riser, which would require major decontamination [7]. |

| Reach-Assisting Tool (e.g., Swiffer, extendable mop) | Allows for safe and thorough cleaning of all interior surfaces, including the back wall, without the user having to place their head inside the BSC [17] [24]. |

| AZD8154 | AZD8154, CAS:2215022-45-8, MF:C27H29N5O4S2, MW:551.7 g/mol |

| SL-176 | SL-176, MF:C24H48O4Si2, MW:456.8 g/mol |

BSC Decontamination & Certification Workflow

The following diagram illustrates the logical workflow for maintaining a biological safety cabinet, from daily operations to mandatory professional interventions.

Experimental Protocol: Standard Surface Decontamination

This detailed methodology outlines the proper procedure for decontaminating the interior surfaces of a BSC.

Objective: To remove and inactivate biological contaminants from all accessible interior surfaces of the biological safety cabinet, ensuring a sterile work environment for personnel and product protection.

Materials:

- Appropriate disinfectant (e.g., 1:10 fresh bleach, or a laboratory-validated disinfectant)

- 70% Ethanol or Isopropyl Alcohol (in a squirt bottle or as pre-wetted wipes)

- Heavy-weight, lint-free wipes

- Reach-assisting tool (e.g., Swiffer, extendable mop)

- Biohazard bag for waste

- Personal Protective Equipment (PPE): lab coat, gloves, and safety glasses

Methodology:

- Preparation: Turn on the BSC and allow it to run for at least 5 minutes to purge stagnant air and airborne particles [7] [9]. Don appropriate PPE. Ensure the sash is at the correct operational height [17].

- Remove Materials: Remove all items from the cabinet, including racks, trays, and waste containers. Decontaminate the outer surfaces of any items that will remain near the BSC [17].

- Apply Disinfectant: Apply the primary disinfectant to all interior surfaces, including the work surface, side walls, back wall, and the interior of the glass view screen. Do not spray disinfectant directly into the cabinet, as aerosolized chemicals can damage HEPA filters and components. Instead, apply the disinfectant to a wipe or use a squirt bottle aimed at the wipe [17].

- Systematic Wiping: Wipe all surfaces using a systematic pattern—top to bottom and from the cleanest area to the dirtiest—to avoid recontaminating cleaned areas [9] [27]. Use the reach-assisting tool to clean the back wall and upper areas without leaning into the cabinet.

- Contact Time: Ensure all surfaces remain wet for the full contact time specified by the disinfectant manufacturer to achieve effective kill [17].

- Rinse (if required): If using a corrosive disinfectant like bleach, perform a second wiping with 70% ethanol or sterile water to remove residual chlorine and prevent corrosion of stainless steel surfaces [7] [24].

- Final Steps: Place all used wipes and cleaning materials into a biohazard bag for disposal. Allow the BSC to run for 2-3 more minutes with no activity to purge any dislodged particles before beginning work or shutting down [7].

Personal Protective Equipment (PPE) and Preparatory Steps for Safe Cleaning Operations

Frequently Asked Questions (FAQs)

What is the minimum PPE required for cleaning a Biological Safety Cabinet (BSC)? At a minimum, you must wear a lab coat and gloves (pulled over the cuff of the lab coat) [17] [15]. Depending on the biological agents used and the disinfectants selected for cleaning, additional PPE such as eye or face protection may be warranted based on a risk assessment [17] [28].

How long should the BSC blower run before I start cleaning or working? Operate the cabinet blowers for at least 3 to 5 minutes before you begin work or cleaning procedures [15] [29]. This purge time allows the cabinet to remove airborne contaminants and establish proper airflow patterns [7].

Why shouldn't I use spray bottles to apply disinfectant inside the BSC? Aerosolizing disinfectant via spraying is not recommended because it can damage the HEPA filters or mechanical components and lead to corrosion [17]. Instead, apply disinfectant using a squirt bottle (to pour onto a wipe) or use pre-moistened wet wipes [17] [30].

Can I use a Bunsen burner inside a BSC for sterility? No, open flames are not recommended in modern BSCs [7] [29]. They create turbulence that disrupts the protective air curtain, can compromise sterility by generating aerosols, and pose a fire risk [29]. The sterile environment is maintained by HEPA-filtered air, making flames unnecessary [29]. Use sterile disposable loops or electric "furnaces" as alternatives [29].

What is the most critical ergonomic adjustment before starting? Ensure the sash is at the correct height (typically 8-10 inches, but consult manufacturer guidelines) and that you are able to sit and work comfortably [17] [15]. Your face should be above the front opening to both see properly and remain outside the containment area [15].

Troubleshooting Common Issues

| Problem | Possible Cause | Solution |

|---|---|---|

| Alarming or erratic airflow [17] | Sash at incorrect height; blocked front or rear grilles; mechanical failure. | Check and adjust sash height [17]. Ensure no items obstruct grilles [17]. Contact your facility manager or certification professional for service and recertification [17]. |

| Ineffective surface decontamination | Incorrect disinfectant contact time; improper wiping technique; unsuitable disinfectant for the biological agent. | Ensure surfaces remain wet for the full contact time per manufacturer instructions [17]. Adopt a systematic wiping pattern (top-to-bottom, clean-to-dirty) [30]. Select an agent-appropriate disinfectant [17]. |

| Contamination of cell cultures | Disrupted airflow curtain; working too close to grille; contaminated gloves or supplies. | Allow cabinet purge time pre-use [15]. Perform all work at least 4-6 inches inside the cabinet [17] [7]. Disinfect gloves with 70% IPA before starting and minimize quick movements [30]. |

| Physical strain or inability to reach all surfaces | Poor ergonomics; lack of proper tools for deep cleaning. | Adjust stool height for a comfortable position [15]. Use an extendable wet mop or reach-assisting tool to clean all surfaces without inserting your head inside the BSC [17]. |

Experimental Protocol: BSC Decontamination and Cleaning

Objective

To establish a standardized methodology for the safe and effective decontamination and cleaning of a Class II Biological Safety Cabinet (BSC) prior to and following experimental procedures involving biological agents.

Pre-Cleaning Preparatory Steps

- PPE Donning: Put on a buttoned lab coat and gloves. Select additional eye protection if splashes are anticipated [15] [28].

- Cabinet Activation: Turn on the BSC and allow the blower to run for a minimum of 5 minutes to purge stagnant air [15] [7].

- Material Gathering: Gather all necessary cleaning supplies, ensuring they are compatible with the BSC surface and the biological agents used. Limit supplies to only what is needed to reduce clutter [17].

- Sash Adjustment: Verify that the sash is at the manufacturer's recommended height, usually between 8 and 10 inches [17] [15].

- Glove Disinfection: Wipe gloves with 70% Isopropyl Alcohol (IPA) and deionized water to prevent introducing external contaminants [30].

Detailed Cleaning Methodology

- Apply Disinfectant: Pour an agent-appropriate disinfectant onto a heavy, non-shedding wipe or apply a pre-moistened wipe. Do not spray [17].

- Systematic Wiping: Wipe all interior surfaces in a systematic pattern.

- Contact Time: Ensure all disinfected surfaces remain wet for the full contact time specified by the disinfectant manufacturer to achieve effective decontamination [17].

- Rinsing (if required): If using a corrosive disinfectant like bleach, wipe the surfaces a second time with 70% ethanol or sterile water to prevent corrosion of the stainless steel [7].

- Final Drying: Allow all surfaces to air dry completely.

Post-Cleaning Procedures

- Material Removal: Remove and properly dispose of all cleaning materials and waste from the BSC.

- Surface Decontamination: Disinfect the outer surfaces of any items removed from the BSC [17].

- Cabinet Operation: Let the BSC run for 2-3 minutes with no activity after cleaning to purge any airborne contaminants generated during the process [7].

- PPE Doffing: Remove gloves and lab coat in a manner that prevents skin contamination, followed by handwashing [15].

BSC Cleaning Workflow

Research Reagent Solutions

| Item | Function/Brief Explanation |

|---|---|

| 70% Ethanol (IPA) | A common disinfectant and cleaning agent; effective for surface decontamination and degreasing. Water content aids in protein coagulation, enhancing efficacy [17] [29]. |

| Sodium Hypochlorite (Bleach) | A broad-spectrum chemical disinfectant effective against viruses and bacteria. Requires a follow-up wipe with ethanol or water to prevent corrosion of BSC stainless steel surfaces [7]. |

| Sterile, Deionized Water | Used as a rinse to remove corrosive disinfectant residues from surfaces, preventing long-term damage to the BSC [17] [7]. |

| Non-Shedding Wipes | Heavy-duty wipes or disposable towels used to apply disinfectants without leaving lint or fibers that could clog HEPA filters or contaminate work [17] [7]. |

| Extendable Wet Mop/Reach Tool | A tool that allows the operator to safely and effectively reach all interior surfaces of the BSC (e.g., the back wall and ceiling) without compromising posture or inserting their head into the cabinet [17]. |

Quantitative Data for BSC Operations

| Operational Parameter | Required Time/Distance | Key Rationale |

|---|---|---|

| Pre-Use Purge | 3 - 5 minutes [15] [29] | Allows cabinet airflow to stabilize and purge airborne contaminants from the work area [7]. |

| Post-Use Purge | 2 - 3 minutes [7] | Lets cabinet air flow purge contaminants generated during work before the cabinet is shut down [7]. |

| Work Distance from Grille | Minimum 4 inches [7] | Performing work at this distance prevents disruptive airflow and maintains the integrity of the air curtain at the front opening [17] [7]. |

| Disinfectant Contact Time | Manufacturer-specified duration | Surfaces must remain wet for the full contact time to ensure effective killing of the target biological agents [17]. |

| Annual Recertification | Every 12 months [17] [7] | Ensures the BSC's filters, airflow, and containment capabilities remain in good working condition [17]. |

Step-by-Step Guide: Daily, Weekly, and Deep Cleaning Procedures for BSCs

Preparation Checklist for Biosafety Cabinet Cleaning

| Preparation Step | Key Actions | Technical Specifications & Rationale |

|---|---|---|

| Power Purge | Allow the cabinet to run with no activity before cleaning. [31] [7] | Duration: 5-15 minutes. [32] [31] [7] Purpose: Allows the cabinet's airflow to stabilize and purge airborne contaminants from the work area. |

| Personal Protective Equipment (PPE) | Don appropriate PPE before gathering materials or starting the clean. [32] [33] | Required Gear: Lab coat or gown, gloves, and safety goggles. [32] [33] [31] Rationale: Protects the user from exposure to disinfectants and any residual biohazards. |

| Material Gathering & Inspection | Assemble all necessary cleaning materials before beginning. [33] | Essential Items: Appropriate disinfectants (e.g., 70% ethanol), lint-free wipes, biohazard bags for waste, and a dedicated cleaning kit. [32] [33] Inspection: Visually check the cabinet for any obvious damage or obstructions. [31] |

Research Reagent Solutions for Decontamination

| Item | Primary Function & Application Notes |

|---|---|

| 70% Ethanol / Isopropyl Alcohol | General-purpose disinfectant; effective against a wide range of microorganisms and evaporates quickly without residue. [33] [7] |

| Bleach Solution (e.g., 1:10 dilution) | Broad-spectrum disinfectant for more stubborn contaminants; requires a subsequent wipe with ethanol or sterile water to prevent corrosion of stainless steel surfaces. [33] [7] |

| Lint-Free Wipes | For applying disinfectants; designed to clean surfaces without leaving behind particulates that could contaminate the work zone. [33] |

| Biohazard Bags/Containers | For the safe containment and disposal of contaminated cleaning waste, such as used wipes. [7] |

Pre-Cleaning Workflow

Troubleshooting Guide: Pre-Cleaning FAQs

Q1: The airflow alarm on my biosafety cabinet is sounding when I turn it on for the pre-cleaning purge. What should I do?

A: If the airflow alarm activates, pause and do not begin cleaning. [31] First, check for any obvious blockages at the front or rear grilles and ensure the viewing sash is at the correct height. [31] If the alarm persists, the issue may be with the cabinet's blower motor, a clogged HEPA filter, or a sensor malfunction. [34] Do not use the cabinet until the issue is resolved by a qualified technician. [31]

Q2: Can I use wipes with chloride-based disinfectants for routine cleaning?

A: It is recommended to use caution with chloride-based cleaners (like bleach) as they can be corrosive to the cabinet's stainless steel surfaces over time. [33] [7] If you must use them for specific decontamination, a second wiping with 70% ethanol or sterile water is necessary to remove residual chlorine and prevent corrosion. [7] Always check the cabinet manufacturer's guidelines for approved cleaning agents.

Q3: How crucial is the 5-15 minute air purge if I'm in a hurry?

A: The air purge is a critical safety step and should not be skipped. [31] [7] This period allows the cabinet to establish stable laminar airflow, which is essential for sweeping airborne contaminants away from the user and out of the work zone. [32] Beginning work or cleaning without a proper purge compromises the cabinet's primary containment function.

Maintaining a systematic cleaning order inside a biological safety cabinet (BSC) is a critical component of contamination control in research and drug development. Adhering to the top-to-bottom and clean-to-dirty principles ensures that contaminants are physically removed from the environment instead of being redistributed over clean surfaces. This protocol is not merely about cleanliness; it is a fundamental engineering control designed to protect both the research personnel and the integrity of the experimental materials being handled [17].

A Class II Biosafety Cabinet, the most common type in labs, protects personnel, products, and the environment through HEPA-filtered inward and downward airflow [35] [36]. Proper cleaning technique is essential to maintain this protection. Disorganized or incorrect cleaning can disrupt the protective air curtain, potentially leading to cross-contamination, compromised research results, or exposure to hazardous biological agents. This guide provides detailed methodologies and troubleshooting advice to integrate these core principles into your daily routine.

Experimental Protocols & Workflows

Detailed Methodology for Systematic Wiping

This protocol provides a step-by-step guide for the correct disinfection of a Biosafety Cabinet before and after use.

Research Reagent Solutions & Essential Materials

| Item | Function & Specification |

|---|---|

| 70% Ethanol | Common disinfectant; effective against many agents, evaporates quickly without residue. Water content aids in microbial membrane penetration [17]. |

| Appropriate Chemical Disinfectant | Selected based on the biological agents used (e.g., diluted bleach, hydrogen peroxide). Must be agent-appropriate [17]. |

| Sterile Wipes (Lint-Free) | For applying disinfectant. Lint-free material prevents introduction of particulate contaminants. |

| Squirt Bottle or Wet Wipes | For applying disinfectant without aerosolization. Spray bottles should not be used as aerosolized disinfectants can damage HEPA filters [17]. |

| Extendable Wet Mop/Reach Tool | Allows for safe and effective cleaning of all interior surfaces without requiring the user to place their head inside the BSC [17]. |

| Biohazard Bag | For the disposal of contaminated wipes and other solid waste. |

Step-by-Step Procedure:

Preparation:

- Turn on the BSC and allow the blower to run for at least 5 minutes to purge stagnant air [17].

- Gather all necessary materials from the "Research Reagent Solutions" table.

- Don appropriate Personal Protective Equipment (PPE): a lab coat and gloves, with eye/face protection as warranted by the biological agents in use [17].

Initial Surface Wetting:

- Apply disinfectant to a lint-free wipe using a squirt bottle or use a pre-moistened wipe. Ensure the wipe is thoroughly damp but not dripping.

Systematic Wiping Execution:

- Top-to-Bottom: Begin wiping the uppermost interior surface of the cabinet (the ceiling).

- Clean-to-Dirty:

- Start with the back wall, wiping from the top to the bottom.

- Then, move to the side walls, again wiping from top to bottom.

- Finally, clean the work surface. Divide the work surface into a grid. Start from the innermost section (farthest from you) and wipe towards the front grill (closest to you). This technique ensures that contaminants are moved towards the front exhaust where they are captured, rather than back into the clean work area.

Contact Time and Final Wipe:

Deeper Cleaning (Periodic):

- Periodically, a deeper clean is required. Lift or remove the work surface to access and clean the spill tray underneath, where spills and debris can accumulate [17].

Systematic Cleaning Workflow: This diagram illustrates the strict sequence of cleaning actions, emphasizing the top-to-bottom and clean-to-dirty progression.

Quantitative Data Table: BSC Performance & Cleaning Metrics

The following table summarizes key quantitative specifications from the NSF/ANSI 49 standard and critical cleaning parameters that ensure BSC performance is maintained.

| Parameter | Specification / Value | Reference / Standard |

|---|---|---|

| Minimum Inflow Velocity | 100 ft/min (0.51 m/s) for Type A2, B1, B2 | NSF/ANSI 49 [35] [37] |

| Typical Downflow Velocity | 55 ft/min (0.28 m/s) | NSF/ANSI 49 [37] |

| HEPA Filter Efficiency | 99.99% for particles ≥ 0.3 μm | NSF/ANSI 49 [37] |

| Maximum Noise Level | ≤ 67 dBA | NSF/ANSI 49 [37] |

| Minimum Illumination | ≥ 800 lux at work surface | NSF/ANSI 49 [37] |

| Disinfectant Contact Time | Manufacturer's specified time (e.g., 5-10 minutes) | Best Practice [17] |

| Work Distance Inside Cabinet | At least 6 inches from front grill | Best Practice [17] |

Troubleshooting Guides

Problem: Consistent Microbial Contamination in Cell Cultures

- Potential Cause 1: Incorrect cleaning technique is spreading contaminants.

- Solution: Strictly re-train on the clean-to-dirty workflow. Ensure the work surface is wiped in sections from the inner, clean area towards the front, dirty exhaust grill. Never use a circular or back-and-forth motion.

- Potential Cause 2: Inadequate disinfectant contact time.

- Solution: Verify that surfaces remain wet for the full manufacturer-recommended contact time. Use a timer to ensure consistency.

- Potential Cause 3: The BSC is due for annual recertification or has a damaged HEPA filter.

- Solution: Contact your facility's Biological Safety Cabinet Program for annual recertification. BSCs must be recertified annually to ensure proper airflow and containment [17].

Problem: Visible Residue on BSC Work Surface After Cleaning

- Potential Cause: Buildup of disinfectant or other chemical residues.

- Solution: After the primary disinfectant contact time is complete, use a wipe moistened with sterile water or 70% ethanol to rinse the surface and remove residues, as this can prevent corrosion [17].

Problem: Disinfectant Dries Too Quickly During Cleaning

- Potential Cause: Low ambient humidity or cleaning too large an area at once.

- Solution: Clean the BSC in smaller sections. For example, completely finish the ceiling and back wall before moving to the sides, and subdivide the work surface to ensure each section stays wet for the required contact time.

Frequently Asked Questions (FAQs)

Q: Can I use a spray bottle to apply disinfectant inside the BSC? A: No. Spraying or aerosolizing disinfectants inside the BSC is strongly discouraged. Aerosolized droplets can be drawn into the sensitive internal components, including the HEPA filters, leading to corrosion and damage. They can also contaminate the supply HEPA filter. Always apply disinfectant directly to a wipe or use pre-moistened wipes [17].

Q: How often should I perform a deeper clean of the spill tray? A: The frequency of deep cleaning depends on how heavily and frequently the BSC is used. A weekly or monthly schedule may be appropriate for high-use cabinets. Inspect the spill tray during deep cleans for accumulated spills, dust, or broken glass, which can lead to contamination events if not addressed [17].

Q: Is a laminar flow hood or fume hood an acceptable substitute for a BSC? A: No. Laminar flow hoods (or clean benches) only protect the product by blowing HEPA-filtered air outward towards the user, offering no personnel protection. Fume hoods are designed for chemical vapors and do not have HEPA filtration for biological agents. Using anything other than a properly certified BSC for work with biohazards poses a significant safety risk [17].

Q: What is the most critical mistake to avoid when wiping the BSC? A: The most critical error is using a disordered or circular wiping pattern that spreads contaminants from dirty areas (like the front grill) back over clean areas (like the back of the work surface). Always adhere to the systematic top-to-bottom and clean-to-dirty principles.

Troubleshooting Contamination Problems: This diagram outlines the logical relationship between a common problem, its potential causes, and the corresponding solutions.

In the context of a broader thesis on cleaning protocols for biological safety cabinets, the selection and correct application of disinfectants are paramount. Biosafety cabinets (BSCs) serve as the primary containment barrier for researchers working with biological agents. Their interior surfaces can become contaminated with a variety of biological materials, including viruses, mycoplasmas, bacteria, and endotoxins, during cell-processing operations and other microbiological procedures. The effectiveness of decontamination procedures directly impacts the safety of personnel, the integrity of research, and the quality of drug development products.

A disinfectant's efficacy is not inherent to its chemical composition alone; it is equally dependent on two critical application parameters: sufficient contact time and proper wiping techniques. Inadequate attention to either factor can result in residual contamination, potentially leading to cross-contamination of experiments, exposure of personnel to biohazards, and compromised cell-product manufacturing. This article addresses specific, evidence-based issues researchers encounter by providing troubleshooting guides and FAQs grounded in current research and established biosafety protocols, thereby supporting the development of robust, risk-based cleaning strategies for the laboratory.

Disinfectant Selection: A Data-Driven Approach

Quantitative Efficacy of Common Disinfectants

Selecting an appropriate disinfectant requires a risk-based assessment that considers the biological material in use. Different classes of microorganisms exhibit varying levels of resistance to chemical disinfectants, influenced by features such as the presence of a lipid envelope or spore formation [38]. The following table synthesizes quantitative data on the efficacy of various disinfectants against different contaminant types, providing a basis for evidence-based selection.

Table 1: Disinfectant Efficacy Against Common Laboratory Contaminants

| Disinfectant | Concentration | Mycoplasma orale | Feline Calicivirus | Endotoxins | Key Considerations |

|---|---|---|---|---|---|

| Benzalkonium Chloride (BKC) | Not Specified | Growth Inhibited [22] | Eliminated [22] | Significantly Reduced [22] | Wiping method effective against viruses and mycoplasma [22]. |

| Ethanol (ETH) | 70% | Detected After Wiping [22] | Information Missing | Not Significantly Reduced [22] | Requires up to 20-minute contact time; evaporates quickly [38]. |

| Sodium Hypochlorite (Bleach) | 1:10 Household Dilution (~0.5%) | Information Missing | Information Missing | Information Missing | Corrosive to stainless steel; inactivated by organic matter [38]. |

| Distilled Water (DW) | N/A | Information Missing | Eliminated [22] | Significantly Reduced [22] | Wiping alone can be effective for viruses and endotoxins [22]. |

Experimental Protocols for Validating Disinfectant Efficacy

The data presented in Table 1 is derived from controlled experimental methodologies designed to objectively evaluate cleaning methods. The following protocol outlines a standard approach for testing disinfectant efficacy on hard surfaces, such as those found in a BSC [22].

Protocol: Evaluating Disinfectant Efficacy on Stainless Steel Surfaces

- Contaminant Preparation and Inoculation: Apply standardized concentrations of test contaminants (e.g., Mycoplasma orale, Feline Calicivirus (FCV) as a viral surrogate, or E. coli endotoxins) onto sterile stainless steel plates (e.g., SUS304 grade). Allow the inoculum to dry under controlled conditions.

- Application of Cleaning Method: Subject the contaminated plates to the test cleaning methods. These methods can include:

- UV Irradiation: Expose plates to UV light at a defined intensity and duration (e.g., 200 mJ/cm² for 20 minutes) [22].

- Chemical Wiping: Wipe the plate surface with a cloth soaked in a specific disinfectant (e.g., BKC, 70% ethanol, or distilled water) using a standardized technique.

- Post-Treatment Analysis: After application of the cleaning method, analyze the plates for residual contamination using appropriate assays:

- Mycoplasma: Culture the plate surface in liquid medium for up to two weeks to detect any viable growth [22].

- Virus (FCV): Use the TCIDâ‚…â‚€ assay (50% Tissue Culture Infective Dose) on Crandell Rees feline kidney (CRFK) cells to quantify remaining infectious viral particles [22].

- Endotoxins: Employ a standardized endotoxin testing method (e.g., Limulus Amebocyte Lysate) to measure the quantity of residual endotoxins [22].

- Data Comparison: Compare the results from the treated plates against positive (contaminated, not cleaned) and negative (sterile) controls to determine the log reduction in contamination achieved by each method.

Troubleshooting Common Disinfection Problems

Frequently Asked Questions (FAQs)

Table 2: Troubleshooting Common Disinfection Issues

| Question | Answer |

|---|---|

| Why is my disinfectant not working despite regular use? | The most common causes are insufficient contact time (the disinfectant is wiped off before it can act) and inactivation by organic matter (e.g., blood, serum). Always check the manufacturer's recommended contact time and pre-clean visibly soiled surfaces [38]. |

| Is 70% ethanol a sufficient disinfectant for all applications? | No. While 70% ethanol is effective against many organisms, it failed to eliminate mycoplasma and did not significantly reduce endotoxins in a controlled study. Its effectiveness is highly dependent on saturating the surface and allowing for a contact time of up to 20 minutes, which is often not achieved in practice due to rapid evaporation [38] [22]. |

| How should I apply disinfectant in a BSC to avoid damage? | Never spray disinfectants directly inside the BSC. Spraying can introduce corrosive chemicals into sensitive internal components and create aerosols. Instead, apply the disinfectant with a squeeze bottle onto a cloth or wipe, and then carefully wipe the surface. After using corrosive agents like bleach, a rinse with 70% ethanol or sterile water is recommended to prevent corrosion of the stainless steel [38] [11]. |

| What is the proper wiping technique to ensure full decontamination? | Use a systematic, overlapping "S"-pattern, moving from the cleanest area to the dirtiest. After wiping a surface with disinfectant, the surface must remain wet for the entire recommended contact time to ensure microbial inactivation. Do not use a dry cloth to immediately wipe off the applied disinfectant [38] [39]. |

Decision Guide for Disinfectant Selection

The following diagram illustrates a logical pathway for selecting an appropriate disinfectant based on the primary contaminant of concern, integrating findings from recent research.

Diagram 1: Disinfectant Selection Logic

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Essential Materials for Biosafety Cabinet Decontamination

| Item | Function / Purpose |

|---|---|

| 70% Ethanol (ETH) | A broad-spectrum disinfectant effective against many vegetative bacteria and lipid-enveloped viruses. Requires careful attention to contact time as it evaporates quickly [38] [22]. |

| Sodium Hypochlorite (Bleach) | A powerful oxidizing agent that kills most organisms, including viruses and bacteria. Must be diluted appropriately (e.g., 1:10) and is inactivated by organic matter. Corrosive to stainless steel [38]. |

| Benzalkonium Chloride (BKC) | A quaternary ammonium compound effective against viruses like feline calicivirus and mycoplasma, particularly when combined with UV irradiation [22]. |

| Distilled Water (DW) | Used as a control in studies and found to be effective in removing viruses and endotoxins via the physical action of wiping. Also used to rinse corrosive disinfectant residues from stainless steel surfaces [22] [11]. |

| Lint-free Wipes | Critical for applying disinfectants without leaving fibers behind, which can interfere with airflow or contaminate sensitive samples. |

| Squeeze Bottle | The recommended tool for applying disinfectants within a BSC to prevent aerosol generation and avoid driving corrosive chemicals into the cabinet's internal components [38]. |

| Avobenzone-13C-d3 | Avobenzone-13C-d3 Stable Isotope |

| Nrf2 (69-84) | Nrf2 (69-84), MF:C86H124N18O28, MW:1858.0 g/mol |

Daily and Session-Based Cleaning Protocols for Routine Decontamination

Standard Operating Procedures for Routine Decontamination

Session-Based Cleaning Protocol

Perform this procedure before and after every work session within the Biological Safety Cabinet (BSC).

- Preparation: Turn on the BSC and allow the blower to run for at least 5 minutes to purge airborne contaminants from the work area [7]. Gather all necessary cleaning materials, including appropriate disinfectants and lint-free wipes or towels [33].

- Personal Protective Equipment (PPE): Don a long-sleeved lab coat with knit cuffs and disposable gloves [7] [40]. Eye or face protection may be warranted based on the biological agents used [17].

- Surface Disinfection: Thoroughly disinfect all interior surfaces—including the work surface, walls, and the interior of the view screen—using an appropriate disinfectant [17]. Apply the disinfectant by pouring it onto a wipe or using pre-moistened wipes; never spray disinfectant inside the BSC, as aerosolized chemicals can damage HEPA filters or other components [17]. Ensure surfaces remain wet for the full contact time specified by the disinfectant manufacturer [17].

- Final Steps: After the contact time, if a corrosive disinfectant like bleach was used, wipe the surfaces a second time with sterile water or 70% ethanol to remove residual chlorine that can corrode stainless steel [7]. Allow the BSC to run for 2-3 minutes with no activity after removing all materials before shutting it down [7].

Daily and End-of-Day Cleaning

A more thorough cleaning should be performed at the end of each day or if the cabinet is used multiple times per day by different users.

- Work Surface: The work surface must be cleaned daily or after each use to prevent cross-contamination between experiments [33].

- Full Interior Wipe-Down: In addition to the session-based protocol, ensure all corners, crevices, and the underside of the work surface (if accessible) are wiped down. Be careful when cleaning the underside of the work surface and the basin of the BSC that wipes are not pulled into the riser on the backside, as this can necessitate a major decontamination [7].

- Visual Inspection: Check for any spilled or splashed nutrients that may support microbial growth and lead to future contamination [7].

Weekly and Monthly Cleaning

- Weekly Tasks: Clean the interior walls and view screen thoroughly [33]. Ultraviolet (UV) lamps, if present and used, should be turned off and cleaned with 70% ethanol to remove dust and dirt that block germicidal effectiveness [7].

- Monthly Tasks: Clean the front and back grilles by vacuuming and disinfecting to maintain proper airflow [33].

The following workflow summarizes the complete routine decontamination process:

Troubleshooting Guides for Common Decontamination Issues

Airflow and Containment Problems

| Problem | Possible Cause | Solution |

|---|---|---|

| Low or unbalanced airflow [34] | Clogged HEPA filters [34] | Contact qualified technician for inspection and potential filter replacement [5] |

| Excessive turbulence [34] | Obstructed front grill or rear exhaust [7] [34] | Clear all obstructions from grilles; do not place items over air intakes [7] |

| Disruptive room air currents [7] | BSC located near doors, vents, or high-traffic areas [7] | Relocate BSC to a quiet area; minimize door opening/closing during use [7] |

| Inadequate containment | Overloaded BSC or large objects impeding airflow [7] | Remove unnecessary items; keep equipment at least 4 inches inside cabinet window [7] |

Cleaning and Disinfection Failures

| Problem | Possible Cause | Solution |

|---|---|---|

| Persistent contamination [34] | Inadequate cleaning technique or contact time [17] | Ensure surfaces are wet for full manufacturer-recommended contact time [17] |

| Corrosion of stainless steel surfaces [7] | Residual chlorine from bleach not removed [7] | Always follow bleach disinfection with a wipe of 70% ethanol or sterile water [7] |

| Fungal growth or spore liberation [7] | Spilled nutrients not thoroughly removed [7] | Perform careful check for spilled materials after each use [7] |

| Wipes sucked into rear riser [7] | Using lightweight wipes during cleaning [7] | Use heavy clean wipes or disposable towels pre-soaked with disinfectant [7] |

Equipment and Mechanical Issues

| Problem | Possible Cause | Solution |

|---|---|---|

| Alarm activation [5] | Low/high airflow, filter clogging, or system failure [5] | Check alarm panel for error codes; refer to user manual or contact manufacturer [5] |

| Sash movement issues [34] | Dirty tracks, worn cables, or counterbalance problems [34] | Clean and lubricate tracks; contact technician for cable replacement or adjustment [34] |

| UV light ineffective [7] | Dusty bulb, decreased output, or end of lamp life [7] | Clean lamp weekly with 70% ethanol; test output periodically; replace as needed [7] |

Frequently Asked Questions (FAQs)

Q1: Which cleaning agents are appropriate for routine decontamination of a BSC? A1: Common and effective disinfectants include 70% isopropyl alcohol (effective against a wide range of microorganisms and evaporates quickly) and dilute bleach solutions (typically 1:10 dilution for broad-spectrum effectiveness) [33]. However, bleach can be corrosive to metal surfaces if not properly rinsed, so a second wipe with 70% ethanol or sterile water is recommended [7]. The choice of disinfectant should be based on its effectiveness against the biological agents used in the BSC, compatibility with cabinet materials, and safety for personnel [33].

Q2: How often does a BSC require certification, and what triggers the need for it? A2: BSCs must be certified at least annually, according to CDC/NIH guidelines [7]. Additionally, certification is required at the time of initial installation, after moving a BSC, after servicing internal plenums, and after replacing HEPA filters [7]. This certification must be performed by qualified personnel using approved test methods to ensure the cabinet contains biohazardous aerosols effectively [7] [17].

Q3: Can I use a UV light as the primary method for decontaminating my BSC? A3: No. Ultraviolet lamps are not recommended as a primary decontamination method and should never be relied upon alone to disinfect a contaminated work area [7]. Their effectiveness is limited to direct exposure, as dust, dirt, or organic matter can shield microorganisms [7]. UV lights can be used as an optional extra precaution for maintaining decontamination between uses but must be turned off when the room is occupied to protect occupants' skin and eyes from exposure [7].

Q4: What is the proper sequence for cleaning the interior surfaces of the BSC? A4: The cleaning process should always proceed from the cleanest areas to the most contaminated, and from top to bottom [33]. Begin with the ceiling, then move to the back and side walls, followed by the work surface, and finish with the front and back grilles [33]. This method ensures that contaminants are not spread from dirtier areas to cleaner ones during the process.

Q5: What should I do if a spill occurs inside the BSC during an experiment? A5: Keep the cabinet blower on and clean the spill immediately [40]. Replace contaminated PPE, cover the spill with paper towels, and carefully pour an appropriate disinfectant over it, starting at the outside edge and working inward [40]. Allow for the required contact time (e.g., 20 minutes for a 10% bleach solution), then wipe up the material, dispose of it as biohazardous waste, and decontaminate the entire interior surface of the BSC [40].

The Scientist's Toolkit: Essential Reagents and Materials

| Item | Function | Key Considerations |

|---|---|---|

| 70% Isopropyl Alcohol | General disinfection; effective against a wide range of microorganisms and evaporates without residue [33]. | Flammable; requires caution. Less corrosive than bleach but may not be effective against all agents [33]. |

| Sodium Hypochlorite (Bleach) | Broad-spectrum disinfectant; effective against most pathogens at a 1:10 dilution [33]. | Corrosive to stainless steel; must be rinsed with sterile water or 70% ethanol after use [7]. |

| Lint-Free Wipes/Cloths | Applying disinfectant to all interior surfaces without leaving fibers or residue [33]. | Use heavy-duty wipes to prevent them from being drawn into the rear riser, which can damage the cabinet [7]. |

| Personal Protective Equipment (PPE) | Protects the researcher from exposure to hazardous materials and disinfectants [33] [40]. | Includes a long-sleeved lab coat with knit cuffs, disposable gloves, and safety goggles [7] [40]. |

| HEPA Filters | The primary containment barrier; removes airborne particles and microorganisms from incoming and outgoing air [17]. | Must be certified annually and replaced by a qualified professional when needed [7] [5]. |

| GLP-2(3-33) | GLP-2(3-33), MF:C156H242N40O53S, MW:3557.9 g/mol | Chemical Reagent |

| Amycolatopsin A | Amycolatopsin A, MF:C60H98O23, MW:1187.4 g/mol | Chemical Reagent |

FAQs on Spill Tray and Drain Pan Cleaning

Q1: What is the step-by-step procedure for cleaning the spill tray or drain pan after a spill?

After a spill, the spill tray or drain pan requires immediate and thorough decontamination. Follow this detailed protocol:

- Leave the BSC running: Keep the cabinet operational during the initial cleanup to contain aerosols [41] [42].

- Gain access: Lift or remove the main work surface to access the catch basin or drain pan beneath it [41] [17].

- Flood with disinfectant: Ensure the drain valve is closed, then pour an appropriate disinfectant (e.g., a 1:10 dilution of fresh bleach) directly onto the work surface and through the front and rear grilles so that it flows into the drain pan [41]. Do not use large quantities of alcohol due to fire hazard [42].

- Ensure contact time: Allow the disinfectant to sit in the drain pan for an extended period, typically 20 to 30 minutes, to ensure effective decontamination [41] [9].